5309267

Hexagon Flange Head Cap Screw

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins part 5309267, a Hexagon Flange Head Cap Screw, is a vital component in the maintenance and assembly of various Cummins diesel engines. This part is designed to provide secure fastening in applications where a robust and reliable connection is essential. Cummins, a renowned manufacturer in the automotive industry, produces this screw, which is integral to ensuring the structural integrity and operational efficiency of engines. This overview will delve into the specifics of this screw, its design, functionality, and the benefits it offers in engine maintenance.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of fastener characterized by its hexagonal head and a flange beneath the head. The hexagonal head allows for efficient torque application using standard tools, while the flange provides a larger bearing surface that helps distribute the load more evenly. In an engine’s assembly, this screw plays a role in securing various components, ensuring they remain firmly in place under operational stress.

Purpose and Role in Engine Operation

The 5309267 Hexagon Flange Head Cap Screw is designed to play a specific role in the operation and maintenance of Cummins diesel engines. It is used in applications where high tensile strength and resistance to loosening are required. This screw helps in securing critical components, ensuring they withstand the rigors of heavy-duty use. Its design contributes to the overall reliability and safety of the engine by maintaining the integrity of the assembled parts.

Key Features

The 5309267 Hexagon Flange Head Cap Screw boasts several key features that make it suitable for demanding applications. Its hexagonal head design allows for easy and secure tightening using common tools. The flange characteristic provides additional surface area, which helps in distributing the load and preventing the screw from pulling through the material. Additionally, the screw is made from high-quality materials, ensuring durability and resistance to corrosion.

Benefits

Using the 5309267 Hexagon Flange Head Cap Screw offers several benefits. The screw’s design enhances durability, making it resistant to the stresses encountered in engine operations. Its resistance to loosening ensures that secured components remain firmly in place, reducing the risk of failure. Furthermore, the ease of installation, thanks to its hexagonal head, allows for quick and efficient assembly, minimizing downtime during maintenance.

Installation Process

Proper installation of the 5309267 Hexagon Flange Head Cap Screw is crucial for optimal performance and longevity. Begin by ensuring the mating surfaces are clean and free of debris. Use a torque wrench to tighten the screw to the manufacturer’s specified torque settings. This ensures that the screw is neither over-tightened, which could cause damage, nor under-tightened, which could lead to loosening. Regularly check the tightness of the screw during maintenance intervals to ensure it remains secure.

Troubleshooting Common Issues

Common issues with Hexagon Flange Head Cap Screws include loosening over time and corrosion. To address loosening, ensure that the screw is tightened to the correct torque specification during installation. If loosening occurs, re-tighten the screw and inspect the mating surfaces for any damage or wear that may need addressing. Corrosion can be mitigated by using screws made from corrosion-resistant materials and applying a protective coating if necessary.

Maintenance Tips

To prolong the lifespan of the 5309267 Hexagon Flange Head Cap Screw, regular inspections are recommended. Check for signs of wear, corrosion, or loosening during routine maintenance checks. Torque checks should be performed to ensure the screw remains tightened to the specified settings. Additionally, keeping the mating surfaces clean and free of contaminants will help maintain the screw’s performance over time.

Cummins: Manufacturer Overview

Cummins is a well-established manufacturer with a strong reputation in the automotive industry. Known for their commitment to producing high-quality components, Cummins has a long history of innovation and excellence. Their products, including the 5309267 Hexagon Flange Head Cap Screw, are designed to meet the demanding requirements of commercial truck applications, ensuring reliability and performance 1.

Application in Cummins Engines

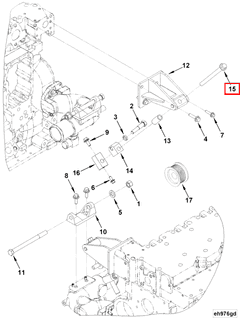

QSB6.7 CM850 (CM2850) and QSB6.7 M CM2250

In the QSB6.7 CM850 (CM2850) and QSB6.7 M CM2250 engines, the Hexagon Flange Head Cap Screw is used in several key areas. These include securing various engine covers, brackets, and other structural components. The screw’s flange head provides a large surface area for torque application, ensuring that the components remain tightly fastened under operational stresses. This is particularly important in maintaining the integrity of the engine’s cooling system and other critical assemblies.

QSB7 CM2880 B117

For the QSB7 CM2880 B117 engine, the Hexagon Flange Head Cap Screw is utilized in similar applications. Given the larger size and power output of this engine, the screw’s ability to withstand higher loads and provide a secure fastening is crucial. It is often used in securing the engine’s main housing, ensuring that all components are properly aligned and fastened to prevent any misalignment or failure during operation.

Importance of the Hexagon Flange Head Cap Screw

The design of the Hexagon Flange Head Cap Screw, with its large flange head and hexagonal shape, allows for efficient torque application using a wrench or socket. This design ensures that the screw can be tightened securely without stripping, which is vital for maintaining the structural integrity of the engine. The material used in the manufacture of this screw is typically high-strength steel, ensuring durability and resistance to the harsh operating conditions within the engine compartment 2.

Installation and Maintenance

Proper installation of the Hexagon Flange Head Cap Screw is essential to ensure the longevity and performance of the engine. Technicians must follow the manufacturer’s torque specifications to avoid over-tightening, which can strip the threads or damage the mating surfaces. Regular maintenance checks should include inspecting these screws for any signs of loosening or damage, ensuring that they remain in optimal condition to perform their critical function.

Role of Part 5309267 Hexagon Flange Head Cap Screw in Engine Systems

Mounting Applications

Part 5309267 Hexagon Flange Head Cap Screw is extensively utilized in mounting applications within engine systems. Its design allows for secure fastening of various components to the engine block or other structural elements. This screw ensures that components remain firmly in place, even under the dynamic conditions experienced during engine operation. The flange head provides additional surface area for distribution of clamping force, reducing the risk of component loosening over time.

Alternator Attachment

In alternator applications, Part 5309267 plays a significant role in securing the alternator to the engine. The alternator, which is responsible for generating electrical power to charge the battery and power the vehicle’s electrical systems, must be mounted securely to ensure consistent performance. The Hexagon Flange Head Cap Screw offers the necessary strength and stability for this critical connection. Its design helps in maintaining the alignment and integrity of the alternator, ensuring efficient power generation and transfer 3.

Conclusion

The Cummins part 5309267, a Hexagon Flange Head Cap Screw, is an essential component in the assembly and maintenance of Cummins diesel engines. Its design, featuring a hexagonal head and a flange, ensures efficient torque application and secure fastening of critical components. The screw’s high-strength material and resistance to corrosion make it suitable for demanding engine applications. Proper installation and regular maintenance are crucial to ensure the longevity and performance of the engine. Cummins’ commitment to quality and innovation is evident in the design and functionality of this part, contributing to the reliability and efficiency of their diesel engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.