This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5335865 Hexagon Flange Head Cap Screw is a specialized fastener designed for use in commercial trucks. It is engineered to provide secure and reliable fastening in various truck components, ensuring the integrity and performance of the vehicle. This screw is particularly valued for its robust design and functionality in demanding environments.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of bolt characterized by its hexagonal head and flanged base. The hexagonal head allows for efficient tightening and loosening using a wrench or socket, while the flange provides additional surface area for distribution of clamping force. This design helps prevent the screw from sinking into the material it is fastening, enhancing stability and security. Within mechanical systems, these screws play a role in joining components together securely, ensuring that parts remain in place under operational stress 1.

Purpose and Role in Truck Operation

The 5335865 Hexagon Flange Head Cap Screw serves a specific role in the operation of a truck by securing various components that are subject to vibration and stress. It is commonly used in applications such as engine mounts, transmission housings, and chassis components. By providing a strong and stable connection, this screw helps maintain the structural integrity of the truck, ensuring that parts remain securely fastened during operation 2.

Key Features

The 5335865 Hexagon Flange Head Cap Screw features a hexagonal head design that facilitates easy and precise tightening. The flange at the base of the screw head distributes clamping force more evenly, reducing the risk of damage to the fastened material. Additionally, the screw is typically made from high-strength materials, offering enhanced durability and resistance to corrosion. These features contribute to its reliability in demanding truck applications.

Benefits

Using the 5335865 Hexagon Flange Head Cap Screw offers several advantages. Its durable construction ensures long-lasting performance, even in harsh operating conditions. The flange design provides resistance to loosening, which is particularly important in applications where vibrations are common. Additionally, the hexagonal head allows for straightforward installation and removal, making it a practical choice for maintenance and repair tasks.

Installation Process

Proper installation of the 5335865 Hexagon Flange Head Cap Screw involves several steps to ensure a secure and lasting connection. Begin by cleaning the fastening area to remove any debris or contaminants. Use a wrench or socket to tighten the screw to the specified torque, which ensures that the correct amount of clamping force is applied without over-tightening. It is important to follow the manufacturer’s torque specifications to avoid damaging the screw or the fastened components.

Common Applications

The 5335865 Hexagon Flange Head Cap Screw is versatile and finds applications in various parts of commercial trucks. It is commonly used in engine components, transmission systems, and chassis assemblies. Its robust design makes it suitable for securing heavy-duty parts that are exposed to significant stress and vibration.

Troubleshooting and Maintenance

To ensure the longevity of the 5335865 Hexagon Flange Head Cap Screw, regular inspection and maintenance are recommended. Check for signs of corrosion, wear, or loosening, and address any issues promptly. If a screw appears damaged or worn, it should be replaced to maintain the integrity of the fastening. Additionally, ensuring that all screws are tightened to the correct torque during installation can prevent future problems.

Safety Considerations

When working with the 5335865 Hexagon Flange Head Cap Screw, it is important to observe several safety guidelines. Always use the appropriate tools to avoid damaging the screw or the wrench. Ensure that the work area is clean and free from hazards. Follow all torque specifications to prevent over-tightening, which can lead to damage. Additionally, wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against injury.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the demanding needs of commercial vehicles, ensuring reliable performance and durability.

Cummins Hexagon Flange Head Cap Screw 5335865 in Engine Applications

The Cummins part number 5335865, a Hexagon Flange Head Cap Screw, is a critical component in various Cummins engine models. This part is designed to provide secure fastening in applications where high strength and durability are essential. Below is a detailed description of how this screw is utilized across different Cummins engine series.

B4.5 and B6.7 Series

The B4.5 CM2350 B135B and B6.7 CM2350 B135B engines both utilize the 5335865 screw in several key areas. These engines are known for their robust design and are often used in heavy-duty applications. The screw is typically employed in securing components that require a reliable fastening solution, such as engine mounts, brackets, and various covers. Its flange head design ensures a large bearing surface, which is crucial for distributing loads evenly and preventing damage to the fastened parts.

F3.8 Series

The F3.8 CM2350 F120B engine also incorporates the 5335865 screw in its assembly. This engine is designed for versatility and efficiency, often used in both industrial and mobile applications. The screw’s role here is similar to its function in the B series engines, providing critical fastening for engine mounts and other structural components. The flange head allows for easy access and removal, which is essential during maintenance and repair operations.

ISB4.5 Series

In the ISB4.5 CM2350 B104 engine, the 5335865 screw is used in several high-stress areas. This engine is known for its durability and is often found in on-highway and off-highway applications. The screw’s application in this engine includes securing various engine covers and brackets, ensuring that these components remain tightly fastened under the demanding conditions of heavy-duty operation.

QSK95 Series

The QSK95 CM2350 K113 engine, a high-performance model, also employs the 5335865 screw. This engine is designed for demanding applications, such as power generation and marine use. The screw’s use in this engine is critical for maintaining the integrity of engine mounts and other structural components that are subjected to significant stress and vibration.

Grouping by Application

The 5335865 screw is a versatile component that finds application across multiple Cummins engine series. Its use in securing engine mounts, brackets, and covers is consistent across the B4.5, B6.7, F3.8, ISB4.5, and QSK95 engines. This commonality highlights the importance of reliable fastening solutions in ensuring the longevity and performance of these engines. The screw’s design, with its flange head and hexagonal shape, provides the necessary strength and ease of use required in these demanding environments.

Role of Part 5335865 Hexagon Flange Head Cap Screw in Engine Systems

The part 5335865 Hexagon Flange Head Cap Screw is integral in securing various components within engine systems, ensuring stability and proper function.

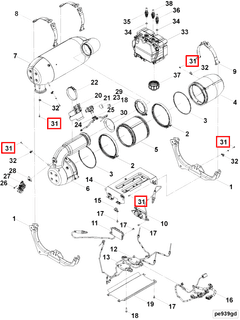

Aftertreatment Arrangement

In the aftertreatment arrangement, this screw is used to fasten components that are essential for reducing emissions. It secures parts such as catalytic converters and diesel particulate filters, ensuring they remain in place under the stress of engine operation. The flange head design provides a larger surface area for distribution of clamping force, minimizing the risk of component loosening.

Aftertreatment Device

For aftertreatment devices, the Hexagon Flange Head Cap Screw plays a role in attaching sensors and monitoring equipment. These devices often include temperature sensors and pressure sensors that need to be firmly mounted to provide accurate readings. The screw’s design allows for easy installation and removal, facilitating maintenance and replacement of sensors without causing damage to the device.

Aftertreatment System

Within the aftertreatment system, this screw is employed to connect various subsystems, such as the selective catalytic reduction (SCR) system and the exhaust gas recirculation (EGR) system. It ensures that all components are securely fastened, which is vital for the efficient operation of the aftertreatment processes. The robust nature of the flange head also helps in withstanding vibrations and thermal expansions typical in aftertreatment systems.

Sensor Bracket

The screw is also utilized in securing sensor brackets. These brackets hold critical sensors that monitor various parameters like oxygen levels, temperature, and pressure within the engine system. The flange head provides additional torque application capability, ensuring that the sensors remain fixed in their optimal positions for accurate data collection.

Conclusion

The Cummins 5335865 Hexagon Flange Head Cap Screw is a reliable and essential component in the operation and maintenance of commercial trucks and Cummins engines. Its robust design, ease of use, and durability make it a critical fastening solution for various applications, ensuring the integrity and performance of engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.