This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Head Cap Screw is a fundamental component in the maintenance and assembly of commercial trucks. It is utilized for its robust fastening capabilities and is integral to ensuring the structural integrity of various truck components. Cummins, a renowned manufacturer in the automotive industry, produces the 137768 Hexagon Head Cap Screw, which is designed to meet the demanding requirements of commercial truck operations. This overview provides insight into the significance of this screw in truck maintenance and introduces Cummins as a leading manufacturer.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is characterized by its hexagonal head, which allows for efficient tightening and loosening using a wrench or socket. This design ensures a secure fit and reduces the risk of cam-out during installation. Typically, these screws are made from materials such as carbon steel, stainless steel, or alloy steel, each offering distinct properties like tensile strength, durability, and corrosion resistance. The choice of material depends on the specific application and environmental conditions the screw will encounter 1.

Purpose of the 137768 Hexagon Head Cap Screw in Truck Operation

The 137768 Hexagon Head Cap Screw plays a role in the assembly and maintenance of commercial trucks by securing critical components. It is commonly used in applications such as engine mounts, chassis assemblies, and various structural attachments. Its design ensures a strong and reliable connection, which is vital for the safe and efficient operation of heavy-duty trucks 2.

Key Features of the 137768 Hexagon Head Cap Screw

The 137768 Hexagon Head Cap Screw features a coarse thread, which provides excellent holding power in various materials. The hexagonal head is designed for easy engagement with tools, ensuring precise installation. Additionally, this screw may include special coatings or treatments, such as zinc plating or black oxide finish, to enhance corrosion resistance and prolong service life 3.

Benefits of Using Cummins Hexagon Head Cap Screws

Cummins-manufactured Hexagon Head Cap Screws offer several advantages. These include superior durability, which is crucial for withstanding the rigors of commercial truck use. The screws also exhibit excellent corrosion resistance, ensuring longevity even in harsh environments. Furthermore, their performance under stress is notable, providing reliable fastening solutions for critical truck components 4.

Installation Guidelines

Proper installation of the 137768 Hexagon Head Cap Screw is vital for optimal performance. Begin by ensuring the mating surfaces are clean and free of debris. Use the appropriate wrench or socket to tighten the screw to the specified torque setting, which ensures a secure fit without over-tightening. It is also important to periodically check the screw for any signs of loosening or damage during routine maintenance.

Troubleshooting Common Issues

Common issues with Hexagon Head Cap Screws include loosening, corrosion, and damage. To address loosening, re-tighten the screw to the recommended torque specification. Corrosion can be mitigated by applying a protective coating or replacing the screw if significant degradation is present. Damage to the screw may require replacement to maintain the integrity of the fastened components.

Maintenance Tips

Regular maintenance checks are recommended to ensure the continued reliable operation of Hexagon Head Cap Screws. Inspect screws for signs of wear, corrosion, or loosening during routine service intervals. Cleaning the screws and applying a protective coating can help prevent corrosion and extend their service life. Additionally, replacing screws that show significant wear or damage is advisable to maintain the structural integrity of the truck.

Cummins as a Manufacturer

Cummins has a long-standing reputation in the automotive industry for producing high-quality components. Founded in 1919, the company has consistently demonstrated a commitment to innovation and excellence. Cummins’ focus on quality assurance and continuous improvement ensures that their products, including the 137768 Hexagon Head Cap Screw, meet the highest standards of performance and reliability.

Hexagon Head Cap Screw 137768 in Cummins Engines

The Hexagon Head Cap Screw, part number 137768, manufactured by Cummins, is a critical component in the assembly and maintenance of several Cummins engine models. This screw is integral to ensuring the structural integrity and operational efficiency of the engines.

G8.3 Engine

In the G8.3 engine, the 137768 screw is utilized in various applications where secure fastening is required. Its design allows for easy installation and removal, making it suitable for frequent maintenance tasks. The screw’s hex head provides a reliable grip for tools, facilitating efficient assembly and disassembly.

N14 CELECT and N14 CELECT PLUS Engines

For the N14 CELECT and N14 CELECT PLUS engines, the 137768 screw is employed in similar capacities. Given the robust nature of these engines, the screw’s strength and durability are essential. It is used in areas where high torque and pressure are common, ensuring that components remain tightly secured under operational stress.

The use of the 137768 screw across these engines highlights its versatility and importance in maintaining the integrity of the engine assemblies. Its design and material properties make it a preferred choice for securing various parts within these engines.

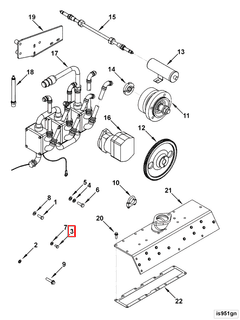

Role of Part 137768 Hexagon Head Cap Screw in Engine Systems

The part 137768 Hexagon Head Cap Screw is integral to the secure assembly and operation of various engine components. Its application spans across multiple systems, ensuring the stability and functionality of the engine.

Ignition System

In the ignition system, the Hexagon Head Cap Screw is utilized to fasten the ignition module to the engine block. This secure attachment is essential for maintaining the module’s position and ensuring consistent performance of the ignition process. Additionally, it helps in grounding the module, which is vital for the proper functioning of the ignition system.

Engine Control Module

The Engine Control Module (ECM) relies on the Hexagon Head Cap Screw for secure mounting. This screw ensures that the ECM remains firmly in place, protecting it from vibrations and external impacts that could otherwise disrupt its operation. The stable mounting is crucial for the accurate processing of sensor data and the delivery of precise control signals to various engine components.

Fuel Plumbing and Supply

Within the fuel system, the Hexagon Head Cap Screw is employed to attach the fuel supply mounting tube and fuel tubing to the engine. This secure connection prevents fuel leaks and ensures a consistent fuel supply to the engine. It also plays a role in maintaining the integrity of the fuel lines under varying pressure conditions.

Wiring and Mounting Harness

The Hexagon Head Cap Screw is essential in the assembly of the wiring and mounting harness. It secures the harness to the engine, ensuring that all electrical connections remain intact and are not compromised by engine vibrations. This is particularly important for the programmed controls group and programmed hardware, where stable electrical connections are paramount for reliable engine operation.

Overall Engine Arrangement

In the broader context of the engine arrangement, the Hexagon Head Cap Screw contributes to the overall structural integrity of the engine. It is used in various points throughout the engine to fasten components, ensuring that the engine remains a cohesive unit capable of withstanding the stresses of operation.

By providing a reliable means of attachment across these diverse engine systems, the Hexagon Head Cap Screw plays a significant role in the efficient and safe operation of the engine.

Conclusion

The 137768 Hexagon Head Cap Screw is a critical component in the maintenance and assembly of commercial trucks and Cummins engines. Its robust design, superior durability, and corrosion resistance make it an essential part for securing various engine components. Proper installation, regular maintenance, and timely replacement are key to ensuring the continued reliability and performance of this Cummins part.

-

Isermann, R. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Peters, G., & Peters, B. J. (2002). Automobile Vehicle Safety. CRC Press.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.