This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Hexagon Head Cap Screw is a critical component in commercial truck maintenance and operation. This screw ensures the secure fastening of various truck parts, contributing to the vehicle’s reliability and safety. Cummins Inc., a leading manufacturer in the commercial vehicle industry, produces the 137796 Hexagon Head Cap Screw, exemplifying Cummins’ commitment to quality and innovation in automotive components 1.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is characterized by its hexagonal head, allowing for efficient tightening and loosening using standard tools such as wrenches or sockets. The screw’s design includes external threads that mate with internal threads in a corresponding part, creating a secure connection. Cap screws are widely used across various industries for their robustness and versatility in fastening applications 2.

Purpose of the 137796 Hexagon Head Cap Screw in Truck Operation

The 137796 Hexagon Head Cap Screw is employed in critical assemblies where secure fastening is paramount. It is commonly used for attaching engine components, securing chassis parts, and fastening body panels. Its use ensures that these components remain firmly in place, contributing to the truck’s structural integrity and performance 3.

Key Features of the 137796 Hexagon Head Cap Screw

The 137796 Hexagon Head Cap Screw is distinguished by several key features that enhance its functionality and durability. These include its material composition, typically a high-strength alloy, which provides resistance to wear and corrosion. The screw features a specific thread type designed for optimal engagement with mating parts, ensuring a secure fit. Additionally, the hexagonal head design facilitates easy manipulation with standard tools, making it a practical choice for various fastening tasks.

Benefits of Using the 137796 Hexagon Head Cap Screw

Incorporating the 137796 Hexagon Head Cap Screw in truck maintenance offers several advantages. Its design contributes to improved fastening security, reducing the risk of component loosening over time. The use of standard tools for installation and removal enhances ease of use, making it a convenient option for maintenance professionals. Furthermore, its resistance to loosening ensures long-term reliability, minimizing the need for frequent re-tightening.

Installation Guidelines

Proper installation of the 137796 Hexagon Head Cap Screw is vital to ensure optimal performance and longevity. It is recommended to follow specific torque specifications provided by the manufacturer to achieve the correct tension without over-tightening, which could damage the screw or the mating part. Using the appropriate tool size and ensuring the screw is aligned correctly with the mating thread are also important practices during installation.

Troubleshooting Common Issues

Frequent problems associated with Hexagon Head Cap Screws include stripping and corrosion. Stripping can occur if the screw is over-tightened or if the wrong tool is used. To prevent this, it is important to use the correct tool size and adhere to torque specifications. Corrosion can be mitigated by selecting screws made from corrosion-resistant materials and by applying protective coatings where necessary.

Maintenance Tips

Regular maintenance of Hexagon Head Cap Screws is essential to prolong their service life. This includes routine inspections for signs of wear, corrosion, or loosening. Cleaning the screws and their mating parts can prevent the buildup of debris that may affect performance. When screws show significant wear or damage, it is advisable to replace them to maintain the integrity of the fastened components.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial vehicle industry, known for its extensive product range and commitment to quality. Founded with a focus on engine manufacturing, Cummins has expanded its offerings to include a variety of components essential for vehicle operation, including the 137796 Hexagon Head Cap Screw. The company’s reputation for innovation and reliability underscores its position as a trusted provider in the automotive sector.

Role of Part 137796 Hexagon Head Cap Screw in Engine Systems

Part 137796, the Hexagon Head Cap Screw, is integral to the assembly and functionality of various engine components. Its robust design ensures secure fastening, which is essential for the reliable operation of the engine system.

Accessory Drive Conversion Kit

In the accessory drive conversion kit, this part is used to fasten components that drive accessories such as alternators, water pumps, and air conditioning compressors. This ensures that these accessories are securely mounted and can operate efficiently without risk of detachment.

Actuator Harness

The actuator harness often requires secure mounting to prevent damage and ensure proper signal transmission. This Cummins part is employed to fasten the harness to the engine frame, providing stability and protection against vibrations.

Base Parts

Base parts, which form the foundational structure of the engine, utilize 137796 to secure various sub-components. This includes mounting brackets, sensor housings, and other critical elements that need to remain firmly in place.

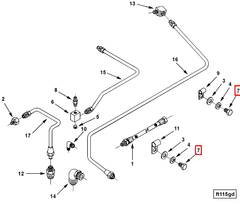

Bypass Mounting Tube

For the bypass mounting tube, 137796 is crucial in attaching the tube to the engine block. This secure attachment ensures that the bypass system functions correctly, allowing for proper fluid flow and temperature regulation.

Cam Follower Mounting Housing

In the cam follower mounting housing, 137796 is used to fasten the housing to the engine block. This secure attachment is vital for the precise operation of the cam followers, which are essential for the timing and efficiency of the engine.

Electric System Kit

The electric system kit includes various components such as sensors, control modules, and wiring harnesses. 137796 is used to mount these components securely, ensuring they remain in place and function correctly under engine operation conditions.

Engine Bill of Materials - Module

Within the engine bill of materials, 137796 is specified for fastening modules that are part of the engine control system. This includes electronic control modules and sensor arrays, ensuring they are correctly positioned and operational.

Engine Control

For the engine control system, 137796 is utilized to secure control units and wiring harnesses. This ensures that the engine control system remains intact and functions reliably, contributing to overall engine performance.

Fuel Supply Mounting Tube

In the fuel supply system, 137796 is used to fasten the fuel supply mounting tube to the engine. This secure attachment is essential for maintaining the integrity of the fuel supply line, ensuring consistent fuel delivery to the engine.

Fuel Tubing

137796 is also employed in the fuel tubing system to secure connections and fittings. This ensures that the fuel lines remain intact and do not leak, which is vital for safe and efficient engine operation.

Harness and Wiring

For harnesses such as the electronic control module wiring and the ETR CNT MDL WRG, 137796 is used to secure these harnesses to the engine frame. This prevents damage from vibrations and ensures reliable electrical connections.

Mounting and Fuel Supply Tube

In the mounting and fuel supply tube assembly, 137796 is critical for securing the tube to the engine. This ensures that the fuel supply remains consistent and that the tube does not shift or detach during engine operation.

Pace Control

The pace control system, which regulates the engine’s speed, uses 137796 to secure its components. This ensures that the pace control system remains operational and can effectively manage engine speed.

Plumbing, Fuel, and Ignition System

In the plumbing, fuel, and ignition systems, 137796 is used to fasten various components such as fuel lines, ignition coils, and plumbing fittings. This secure attachment is essential for the reliable operation of these systems.

Throttle Switch Lever

The throttle switch lever, which controls the engine’s throttle, is secured using 137796. This ensures that the lever remains in place and operates correctly, contributing to the engine’s performance and drivability.

Programmed Controls Group and Programmed Hardware

For the programmed controls group and programmed hardware, 137796 is used to secure control units and sensors. This ensures that these components remain correctly positioned and can operate as intended.

System Ignition

In the system ignition, 137796 is utilized to fasten ignition components such as spark plugs and ignition coils. This secure attachment ensures reliable ignition and consistent engine performance.

Conclusion

The 137796 Hexagon Head Cap Screw by Cummins is a vital component in the maintenance and operation of commercial trucks and engines. Its robust design, ease of use, and resistance to loosening make it an essential part for ensuring the secure fastening of various engine components. Proper installation, regular maintenance, and adherence to torque specifications are crucial for maximizing the performance and longevity of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.