137868

Hexagon Head Cap Screw

Cummins®

AVAILABLE

7 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 137868 Hexagon Head Cap Screw is a specialized fastener designed for use in commercial truck operations. It is engineered to provide secure fastening in various truck components, ensuring the integrity and reliability of the vehicle’s mechanical assemblies. This screw is integral to maintaining the structural and functional stability of commercial trucks, contributing to their overall performance and longevity.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tightening and loosening using standard tools such as wrenches or sockets. These screws are commonly used in mechanical assemblies to secure components together. The hexagonal shape of the head provides a firm grip, reducing the risk of cam-out and ensuring precise torque application. In commercial trucks, these screws play a vital role in maintaining the structural integrity of various parts, from engine components to chassis assemblies 1.

Purpose of the Cummins 137868 Hexagon Head Cap Screw

The Cummins 137868 Hexagon Head Cap Screw is specifically designed to meet the demanding requirements of commercial truck operations. It is used in a variety of applications within the truck, including securing engine components, transmission parts, and chassis assemblies. The screw’s robust design ensures that it can withstand the high stresses and vibrations encountered in heavy-duty truck environments, providing reliable fastening that contributes to the overall performance and safety of the vehicle.

Key Features

The Cummins 137868 Hexagon Head Cap Screw boasts several key characteristics that enhance its functionality and durability. It is typically made from high-strength materials such as alloy steel, which provides excellent resistance to wear and corrosion. The screw features a fine or coarse thread, depending on the application, allowing it to securely fasten components together. The hexagonal head design ensures easy installation and removal using standard tools, while the cap under the head provides additional protection against debris and environmental factors.

Benefits

Using the Cummins 137868 Hexagon Head Cap Screw offers several advantages in truck maintenance and repair. Its high-strength material composition ensures enhanced durability, making it suitable for withstanding the rigors of commercial truck operations. The screw’s design provides excellent resistance to vibration, reducing the likelihood of loosening over time. Additionally, the hexagonal head allows for easy installation and removal using standard tools, simplifying maintenance procedures and reducing downtime.

Installation Guidelines

Proper installation of the Cummins 137868 Hexagon Head Cap Screw is crucial to ensure secure fastening and optimal performance. Begin by cleaning the mating surfaces to remove any debris or corrosion. Use a torque wrench to apply the specified torque, ensuring that the screw is tightened to the manufacturer’s recommended settings. It is important to follow best practices, such as using a thread lubricant in certain applications to prevent seizing and facilitate easier removal in the future. Always verify that the screw is fully seated and that the components are properly aligned.

Troubleshooting and Maintenance

Common issues associated with Hexagon Head Cap Screws include loosening due to vibration, corrosion, and wear. Regular inspection of the screws during maintenance intervals can help identify these issues early. If corrosion is detected, cleaning the affected area and applying a corrosion-resistant coating can help prolong the life of the screw. In cases of wear or damage, replacing the screw with a new one is recommended to maintain the integrity of the fastening. Proper torque application during installation and periodic re-torque checks can also help ensure ongoing performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company is committed to innovation and quality, continually developing advanced technologies and components that enhance the performance, efficiency, and reliability of commercial vehicles. Cummins’ dedication to excellence is evident in its wide range of truck components, including the Cummins 137868 Hexagon Head Cap Screw, which is designed to meet the high standards required for heavy-duty applications.

Role of Part 137868 Hexagon Head Cap Screw in Engine Systems

The Cummins part 137868, a Hexagon Head Cap Screw, is a critical component in the assembly and maintenance of several Cummins engine models. This part is integral to the structural integrity and operational efficiency of the engines, ensuring that various components are securely fastened and aligned.

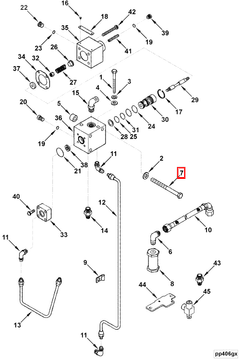

Intake Manifold and Related Components

In the intake manifold, this screw is used to secure the manifold to the engine block, ensuring a tight seal that prevents air leaks. It is also employed in the air intake manifold mounting to maintain structural integrity and alignment. The intake manifold plumbing benefits from the screw’s secure fastening, which is essential for maintaining the correct airflow and pressure within the system.

Aftercooler Systems

For the aftercooler and its associated kits (front and rear), the Hexagon Head Cap Screw plays a significant role in mounting the housing to the engine. This ensures efficient cooling of the compressed air, which is vital for optimal engine performance. The screw’s robust design handles the thermal expansion and contraction that occur within the aftercooler system.

Camshaft and Cylinder Head Mounting

In the camshaft and cylinder head mounting applications, the screw provides the necessary tension to keep these components in place. This is important for maintaining the precise timing and clearances required for the engine’s valves to operate correctly.

Alternator and Support Mounting

The alternator mounting and support mounting systems rely on the Hexagon Head Cap Screw to secure the alternator to the engine block. This ensures stable operation of the alternator, which is crucial for generating electricity to power the engine’s electrical systems.

Lubricating Oil Supply Tube and Mounting

In the lubricating oil supply tube and its mounting, the screw ensures that the tube remains firmly attached to the engine. This is essential for maintaining a consistent flow of lubricant to the moving parts, reducing friction and wear.

Noise Kit Panel and Thermostat Top Level Assembly Housing

The noise kit panel uses the screw to dampen vibrations and reduce noise, contributing to a quieter engine operation. In the thermostat top level assembly housing, it secures the thermostat in place, ensuring accurate temperature regulation within the engine.

Timing Control Valve

Finally, in the timing control valve, the screw ensures that the valve remains securely mounted. This is important for maintaining the precise timing of the engine’s operations, which directly impacts its efficiency and performance.

Conclusion

The Cummins 137868 Hexagon Head Cap Screw is a fundamental component in the assembly and maintenance of Cummins engines. Its robust design and high-strength material composition ensure secure fastening and reliable operation across various engine systems. Proper installation and maintenance of this screw are crucial for the optimal performance and longevity of commercial trucks.

-

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.