This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Part #204249 Hexagon Head Cap Screw is a specialized fastener designed for heavy-duty truck applications. This component plays a significant role in ensuring structural integrity and reliable performance within the truck’s assembly. By providing secure fastening solutions, it contributes to the overall durability and efficiency of the vehicle.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient and secure tool engagement. The hexagonal shape ensures that the screw can be tightened or loosened with minimal risk of slipping, enhancing the precision and reliability of the fastening process. This design is particularly advantageous in applications where consistent torque application is required 1.

Purpose and Role in Truck Operation

This Cummins part serves a specific purpose in heavy-duty truck applications. It is utilized to fasten various components securely, ensuring that critical parts remain firmly in place under demanding conditions. This screw contributes to the truck’s operation by maintaining the structural integrity of assemblies, which is vital for the vehicle’s performance and safety 2.

Key Features

The Cummins Part #204249 Hexagon Head Cap Screw boasts several key features that enhance its performance and durability. These include a robust material composition, typically high-strength steel, which provides excellent resistance to wear and tear. The screw also features a specific thread type designed to offer optimal grip and secure fastening. Additionally, unique design elements may be incorporated to further improve its functionality in heavy-duty applications 3.

Benefits

Using this Cummins part offers several benefits. Its design contributes to improved fastening strength, ensuring that components remain securely attached even under significant stress. The screw’s resistance to loosening helps maintain the integrity of the fastening over time, reducing the need for frequent re-tightening. Furthermore, its compatibility with various truck components makes it a versatile choice for different applications 4.

Installation Guidelines

Proper installation of the Cummins Part #204249 Hexagon Head Cap Screw is crucial for ensuring its effectiveness. Begin by selecting the appropriate tool, typically a hexagonal socket wrench, to engage with the screw’s head. Apply the screw to the designated location, ensuring it aligns correctly with the mating threads. Gradually tighten the screw to the specified torque, using a torque wrench to achieve the recommended setting. This process ensures that the screw is securely fastened without over-tightening, which could lead to damage 5.

Troubleshooting and Maintenance

Common issues with Hexagon Head Cap Screws, such as loosening or corrosion, can be addressed through regular maintenance and inspection. If a screw appears loose, it should be re-tightened to the specified torque. In cases of corrosion, cleaning the affected area and applying a suitable lubricant or corrosion-resistant coating can help prevent further degradation. Regular checks and maintenance will ensure the longevity and optimal performance of the screws 6.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a rich history of producing diesel engines and related technologies for various industries, including heavy-duty trucks. The company’s reputation for quality and innovation has established it as a leader in the field, providing reliable and high-performance components that meet the demanding requirements of modern transportation.

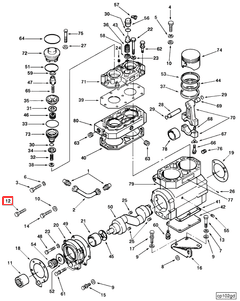

Integration of Hexagon Head Cap Screw 204249 in Cummins Engines

The Cummins Hexagon Head Cap Screw part number 204249 is a critical component in various Cummins engine models, ensuring secure fastening and structural integrity. This screw is designed to withstand high stress and torque, making it suitable for use in demanding engine environments.

N14 CELECT PLUS and N14 MECHANICAL Engines

In the N14 CELECT PLUS and N14 MECHANICAL engines, the 204249 screw is utilized in several key areas. These engines, known for their robust performance, require reliable fastening solutions to maintain the alignment and stability of various engine components. The screw’s design allows for precise torque application, ensuring that parts remain securely fastened under high operational stress.

NH/NT 855 Engines

The NH/NT 855 engines also benefit from the use of the 204249 Hexagon Head Cap Screw. These engines are designed for heavy-duty applications, and the screw’s durability and strength are essential for maintaining the integrity of the engine’s structure. The screw’s hex head provides easy access for tightening and loosening, which is crucial during maintenance and repair operations.

V28 Engines

In the V28 engines, the 204249 screw is employed in various critical applications. The V28 engine is known for its versatility and power, and the screw’s ability to handle high torque and stress is vital for ensuring the longevity and reliability of the engine. The screw’s design allows for efficient assembly and disassembly, facilitating quick maintenance and repair work.

Each of these engine models relies on the 204249 Hexagon Head Cap Screw to maintain the structural integrity and operational efficiency of the engine. The screw’s compatibility with these engines underscores its importance in ensuring reliable performance and durability.

Role of Part 204249 Hexagon Head Cap Screw in Engine Systems

The Part 204249 Hexagon Head Cap Screw is integral to the assembly and securement of various components within engine systems. Its application spans across multiple subsystems, ensuring the structural integrity and operational efficiency of the engine.

Accessory Drive System

In the accessory drive system, the Hexagon Head Cap Screw is employed to fasten the drive components to the engine block or accessory mounting brackets. This securement is vital for maintaining the alignment and tension of the drive belts, which are responsible for operating accessories such as the alternator, power steering pump, and air conditioning compressor.

Air Compressor and Mounting

The air compressor, a key component in the vehicle’s air conditioning system, relies on the Hexagon Head Cap Screw for secure attachment to its mounting bracket. This ensures that the compressor remains firmly in place, allowing for efficient operation and minimizing vibrations that could lead to premature wear or failure.

Compressor and Fuel Pump Mounting

For systems where the compressor is mounted alongside the fuel pump, the Hexagon Head Cap Screw plays a role in securing both components to their shared mounting structure. This not only ensures the stability of each component but also facilitates the maintenance and replacement processes by providing a reliable fastening solution.

Drive Accessory Integration

Within the drive accessory integration, the Hexagon Head Cap Screw is used to attach various accessories to the engine’s accessory drive system. This includes components like the air compressor, ensuring that they are properly aligned and tensioned for optimal performance.

EBM (Electric Blower Motor) Compressor Air Mounting

In systems utilizing an EBM compressor for air conditioning, the Hexagon Head Cap Screw is crucial for securing the compressor to its mounting structure. This application ensures that the compressor operates within the designed parameters, contributing to the overall efficiency and reliability of the air conditioning system.

Compressor Mounting Variations

Across different compressor mounting configurations, whether it’s a standalone compressor mounting or a combined compressor/fuel pump mounting, the Hexagon Head Cap Screw provides the necessary securement. This versatility underscores its importance in maintaining the structural integrity and operational stability of the engine’s auxiliary systems.

Conclusion

The Cummins Part #204249 Hexagon Head Cap Screw is a vital component in heavy-duty truck and engine applications. Its robust design, secure fastening capabilities, and compatibility with various engine systems make it an essential part for maintaining structural integrity and operational efficiency. Proper installation, regular maintenance, and understanding its role in different engine subsystems are crucial for ensuring the longevity and reliability of this fastener.

-

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Rajamani, R. (2005). Vehicle Dynamics and Control. Springer.

↩ -

Harrison, M. (2004). Controlling Noise and Vibration in Road Vehicles. SAE International.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5467668.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5467668.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.