205409

Hexagon Head Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Head Cap Screw, specifically Part #205409 by Cummins, is a vital component in the realm of commercial trucks. Cummins, a renowned manufacturer in the automotive industry, produces this screw, which is integral to the assembly and maintenance of commercial trucks. This overview delves into the specifics of the Hexagon Head Cap Screw, its design, functionality, and the role it plays in truck operations.

Basic Concepts of Hexagon Head Cap Screw

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tightening and loosening using a wrench or socket. The screw’s design includes a threaded shaft that engages with internal threads in the material being fastened, providing a secure connection. In fastening applications, the Hexagon Head Cap Screw is utilized for its strength, reliability, and ease of use, making it a preferred choice in various industrial and automotive settings 1.

Purpose of the 205409 Hexagon Head Cap Screw in Truck Operation

This Cummins part serves a specific role in the assembly and maintenance of commercial trucks. It is employed in various truck components, including engine mounts, chassis assemblies, and other critical areas where secure fastening is required. The screw’s design ensures that it can withstand the rigors of truck operation, providing a reliable connection that contributes to the overall integrity and performance of the vehicle.

Key Features

The 205409 Hexagon Head Cap Screw boasts several key features that enhance its performance and durability. Its hexagonal head design allows for efficient tightening and loosening, reducing the risk of cam-out and providing a secure grip. The screw is composed of high-quality materials, ensuring resistance to corrosion and wear. The threading is designed to provide a strong and secure connection, while any unique attributes, such as a special coating or treatment, further enhance its performance in demanding environments 2.

Benefits

This part offers several benefits that make it an ideal choice for commercial truck applications. These include improved fastening strength, which ensures a secure connection under various operating conditions. The screw’s design also provides resistance to loosening, reducing the need for frequent re-tightening. Additionally, the ease of installation and removal, along with its compatibility with various truck components, makes it a versatile and reliable fastening solution 3.

Installation Guidelines

Proper installation of the 205409 Hexagon Head Cap Screw is crucial for ensuring secure and reliable fastening. The installation process involves selecting the appropriate wrench or socket to match the screw’s hexagonal head. Torque specifications should be followed to achieve the correct tightening force, ensuring a secure connection without over-tightening, which could damage the screw or the material being fastened. Recommended tools and best practices, such as using a torque wrench, should be employed to ensure accurate and consistent installation.

Troubleshooting and Maintenance

Common issues that may arise with Hexagon Head Cap Screws include loosening, corrosion, or damage. Troubleshooting tips involve regularly inspecting the screws for signs of wear or corrosion and addressing any issues promptly. Maintenance procedures may include re-tightening loose screws, applying a corrosion-resistant coating, or replacing damaged screws to ensure continued reliable performance and prolong the screw’s lifespan.

Cummins: Manufacturer Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its commitment to producing high-quality truck components. With a rich history and a strong reputation, Cummins has earned the trust of professionals in the industry. The company’s dedication to quality and innovation is evident in its products, including the 205409 Hexagon Head Cap Screw, which is designed to meet the demanding requirements of commercial truck applications.

Cummins Engine Compatibility with Hexagon Head Cap Screw Part 205409

The Cummins Hexagon Head Cap Screw part number 205409 is a versatile component that finds application across a range of Cummins engines. This screw is designed to secure various parts within the engine assembly, ensuring structural integrity and operational efficiency.

K-Series Engines

The part 205409 is compatible with several K-Series engines, including:

- K19

- K38

- K50

These engines benefit from the screw’s robust design, which helps maintain the alignment and stability of critical engine components.

KTA19GC Engine

The KTA19GC engine also utilizes the 205409 screw, ensuring that the engine’s internal parts remain securely fastened under operational stresses.

M11 Engines

The M11 engine series, which includes both mechanical and CELECT PLUS variants, incorporates the 205409 screw. This ensures that the engine’s electronic and mechanical components are properly secured.

- M11 MECHANICAL

- M11 CELECT PLUS

N14 Engines

The N14 engine series, available in mechanical, CELECT, and CELECT PLUS versions, also relies on the 205409 screw for its assembly. This screw is crucial for maintaining the structural integrity of the engine.

- N14 MECHANICAL

- N14 CELECT

- N14 CELECT PLUS

NH/NT 855 Engine

The NH/NT 855 engine uses the 205409 screw to secure various parts, ensuring the engine operates smoothly and efficiently.

QSK19 Engines

The QSK19 series engines, which include various configurations, utilize the 205409 screw for their assembly. This screw is essential for maintaining the alignment and stability of the engine components.

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

QSK19G Engine

The QSK19G engine also incorporates the 205409 screw, ensuring the engine’s components are securely fastened.

QSK38 Engines

The QSK38 series engines, including the CM2150 MCRS and CM850 MCRS configurations, use the 205409 screw for their assembly.

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

QSK50 Engines

The QSK50 series engines, which include the CM2150 MCRS and CM2350 K108 configurations, also utilize the 205409 screw.

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

QSK50 CM850 MCRS Engine

The QSK50 CM850 MCRS engine incorporates the 205409 screw, ensuring the engine’s components are properly secured.

Role of Part 205409 Hexagon Head Cap Screw in Various Engine Components

The part 205409 Hexagon Head Cap Screw is instrumental in the assembly and functionality of several key components within engine systems. Its robust design and reliable performance make it a preferred choice for securing various parts, ensuring they function as intended under demanding conditions.

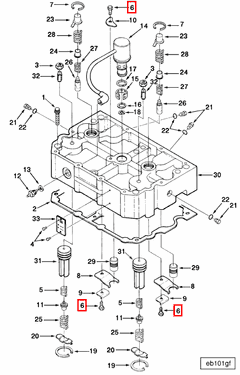

Baffle Plate and Flywheel Housing Baffle

In the baffle plate and flywheel housing baffle, the 205409 screw plays a significant role in maintaining structural integrity. It secures the baffle plate, which is essential for directing airflow and managing temperatures within the engine compartment. Similarly, in the flywheel housing baffle, it ensures that the baffle remains firmly in place, contributing to the efficient operation of the flywheel housing.

Brake Systems

Across different brake systems, including the brake, C brake (top level) kit, C brake kit, and C-brake kit, the 205409 screw is used to fasten components that are vital for the brake’s performance. It secures parts within the brake assembly, ensuring that all elements work in unison to provide reliable braking power.

Clamping and Mounting Plates

The clamping mounting plate and clamping plate kit rely on the 205409 screw to hold various plates and brackets in position. This is particularly important in ensuring that the mounting plates remain stable and do not shift during engine operation, which could lead to misalignment and reduced efficiency.

Engine and Cummins Engine Brake Systems

In the engine and Cummins engine brake systems, the 205409 screw is employed to secure critical components. Whether it’s part of the Cummins engine brake kit or the engine brake overhaul kit, this screw ensures that all brake components are tightly fastened, contributing to the overall effectiveness of the braking system.

Flywheel Housing and Manifolds

The flywheel housing and water manifold both benefit from the secure fastening provided by the 205409 screw. In the flywheel housing, it helps maintain the alignment and integrity of the housing, while in the water manifold, it ensures that connections remain tight, preventing leaks and ensuring efficient water flow.

Oil Pan and Rear Oil Crankshaft Seal

The oil pan and rear oil crankshaft seal are other areas where the 205409 screw is vital. It secures the oil pan, ensuring that it remains sealed and does not leak, while also fastening the rear oil crankshaft seal, which is essential for maintaining proper lubrication and preventing oil loss.

Rocker Housing and Solenoid Mounting Clamp

In the rocker housing and solenoid mounting clamp, the 205409 screw ensures that these components are held firmly in place. This is important for the rocker housing to function correctly and for the solenoid mounting clamp to maintain its position, ensuring the solenoid operates as intended.

Shield and Debris Management

The shield, designed to protect various engine components from debris, also utilizes the 205409 screw. It ensures that the shield remains securely attached, providing the necessary protection against debris that could otherwise cause damage to sensitive engine parts.

Conclusion

In summary, the 205409 Hexagon Head Cap Screw is a versatile and essential component in the assembly and maintenance of various engine systems. Its reliable performance and strong fastening capabilities make it indispensable in ensuring the proper function and durability of these critical engine components.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.