3018006

Hexagon Head Cap Screw

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3018006 Hexagon Head Cap Screw is a component manufactured by Cummins, a well-established name in the automotive industry. This screw is specifically designed for use in commercial trucks, where it plays a role in securing various components and assemblies. Its robust design and high-quality materials make it suitable for the demanding conditions encountered in heavy-duty applications.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tightening and loosening using a wrench or socket. These screws are commonly used in mechanical assemblies to secure components in place. The hexagonal shape of the head provides a firm grip, reducing the risk of cam-out during installation and removal. The threaded shaft of the screw engages with the internal threads of a nut or a tapped hole, creating a secure connection that can withstand significant loads and vibrations 1.

Purpose of the 3018006 Hexagon Head Cap Screw in Truck Operation

In the context of commercial trucks, the 3018006 Hexagon Head Cap Screw serves multiple functions. It is used to fasten critical components in various truck systems, including the engine, transmission, and chassis. By providing a reliable and durable connection, this screw helps maintain the structural integrity and operational efficiency of the truck. Its applications range from securing engine mounts to attaching body panels, ensuring that all parts remain firmly in place under the stresses of heavy-duty use.

Key Features of the 3018006 Hexagon Head Cap Screw

The 3018006 Hexagon Head Cap Screw is designed with several key features that enhance its performance and reliability. Its hexagonal head is meticulously crafted to ensure a precise fit with standard wrenches and sockets, facilitating easy installation and removal. The screw’s thread pitch is optimized for the specific applications it is intended for, providing a strong and secure connection. Additionally, the screw may feature special coatings or treatments to improve its resistance to corrosion and wear, extending its service life in harsh environments 2.

Benefits of Using the 3018006 Hexagon Head Cap Screw

Utilizing the 3018006 Hexagon Head Cap Screw offers several advantages. Its durable construction and high-quality materials contribute to enhanced longevity and reliability. The screw’s design reduces the likelihood of loosening over time, even under dynamic loads and vibrations. Furthermore, the ease of installation and removal simplifies maintenance procedures, allowing for quick and efficient repairs and adjustments.

Installation and Usage Guidelines

Proper installation of the 3018006 Hexagon Head Cap Screw is crucial for ensuring its effectiveness and longevity. To install the screw, use the appropriate wrench or socket to achieve the recommended torque specifications. This ensures that the screw is tightened to the correct level, providing a secure connection without over-tightening, which could damage the screw or the surrounding components. Always use the recommended tools and follow the manufacturer’s guidelines to achieve the best results 3.

Troubleshooting Common Issues

Common issues associated with Hexagon Head Cap Screws include stripping and corrosion. Stripping can occur if the screw is over-tightened or if the wrong tool is used during installation. To prevent this, always use the correct wrench or socket and adhere to the specified torque settings. Corrosion can be mitigated by selecting screws with appropriate coatings or treatments for the environment in which they will be used. Regular inspection and maintenance can help identify and address these issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and reliable performance of the 3018006 Hexagon Head Cap Screw, regular inspection and maintenance are recommended. Check for signs of corrosion, wear, or loosening during routine maintenance checks. If any issues are detected, address them promptly to prevent further damage. Additionally, ensure that all tools used for installation and removal are in good condition and properly sized for the screw to avoid damage.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality, innovation, and customer satisfaction. The company’s extensive product range includes engines, powertrains, and related components for various industries, including commercial trucking. Cummins’ dedication to excellence is evident in the high-quality components it produces, such as the 3018006 Hexagon Head Cap Screw.

Hexagon Head Cap Screw 3018006 in Cummins Engines

The Cummins Hexagon Head Cap Screw part number 3018006 is a versatile component that finds application across a variety of Cummins engine models. This screw is integral in securing various parts and assemblies within the engine, ensuring structural integrity and operational efficiency.

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

The ISM series engines, including the ISM CM570, ISM CM570/870, ISM CM876, and ISM11 CM876 SN, utilize the 3018006 screw in several critical applications. These engines, known for their robust performance and reliability, require precise fastening to maintain their operational standards. The screw is often used in securing engine mounts, brackets, and other structural components that are essential for the engine’s stability and performance.

L10 Series Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

The L10 series engines, comprising the L10 CELECT, L10 GAS, and L10 MECHANICAL variants, also incorporate the 3018006 screw in their design. These engines are designed for heavy-duty applications and require reliable fastening solutions to handle the stresses and strains of their operation. The screw is used in various applications, including securing engine blocks, valve covers, and other critical components.

M11 Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

The M11 series engines, including the M11 CELECT, M11 CELECT PLUS, and M11 MECHANICAL, utilize the 3018006 screw in several key areas. These engines are known for their efficiency and power, and the screw is used to secure various parts, ensuring the engine’s components remain tightly fastened and properly aligned.

QSC8.3 CM850(CM2850) and QSM11 Series Engines

- QSC8.3 CM850(CM2850)

- QSM11 CM570

- QSM11 CM876

The QSC8.3 CM850(CM2850) and QSM11 series engines, including the QSM11 CM570 and QSM11 CM876, also incorporate the 3018006 screw in their design. These engines are designed for specific applications and require reliable fastening solutions to ensure their performance and longevity. The screw is used in securing various engine components, ensuring they remain securely fastened under operational conditions.

QST30 CM552 and V903 Engines

- QST30 CM552

- V903

The QST30 CM552 and V903 engines also utilize the 3018006 screw in their design. These engines, designed for specific applications, require reliable fastening solutions to ensure their components remain securely fastened and properly aligned. The screw is used in securing various parts, ensuring the engine’s performance and reliability.

Role of Part 3018006 Hexagon Head Cap Screw in Engine Systems

The part 3018006 Hexagon Head Cap Screw is integral to the assembly and secure functioning of various engine components. It is commonly used in the connection of the exhaust outlet to the engine, ensuring a tight and reliable seal that prevents exhaust leaks.

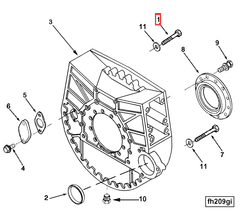

In the engine installation kit, this screw plays a significant role in attaching the engine to the engine supports and mounting brackets, providing the necessary stability during operation. It is also utilized in the assembly of the flywheel housing and flywheel mounting housing, where it secures the housing to the flywheel, ensuring smooth operation and minimizing vibrations.

Furthermore, the screw is employed in the attachment of the flywheel R PTO (Remote Power Take-Off) to the housing, facilitating the transfer of power to auxiliary components. In the mounting of the starting motor, it ensures that the motor is firmly attached to the engine, allowing for reliable starting performance.

During product installation and package assembly, the screw is used to secure various components, such as the plumbing connections to the radiator and the attachment of the rail to the base. It also plays a role in the service tool replacer and shipping bracket assemblies, ensuring that these components are securely fastened during transportation and storage.

In the context of the power train and rear engine support, the screw is used to attach the subbase and support structures, contributing to the overall stability and durability of the engine system.

Conclusion

The 3018006 Hexagon Head Cap Screw is a critical component in the assembly and operation of Cummins engines, particularly in commercial trucks. Its robust design, high-quality materials, and precise engineering make it an essential part for securing various engine components, ensuring structural integrity and operational efficiency. Proper installation, regular maintenance, and adherence to manufacturer guidelines are crucial for maximizing the performance and longevity of this Cummins part.

-

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Asef, P., Padmanaban, S., & Lapthorn, A. (2022). Modern Automotive Electrical Systems. Wiley.

↩ -

Reif, K. (Ed.). (2014). Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.