The Hexagon Head Cap Screw, specifically Part #3020093 by Cummins, is a vital component in the realm of commercial trucks. Cummins, a renowned manufacturer in the industry, produces this screw to meet the demanding requirements of heavy-duty applications. This part is integral to ensuring the structural integrity and reliable operation of various truck components.

Basic Concepts of Hexagon Head Cap Screw

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tightening and loosening using a wrench or socket. The screw’s design includes external threading that engages with internal threads in the mating part, creating a secure connection. In fastening applications, these screws are used to join components together, providing strength and stability 1.

Purpose of the 3020093 Hexagon Head Cap Screw in Truck Operation

This Cummins part plays a specific role in the operation and maintenance of commercial trucks. It is employed in various critical areas where secure fastening is required. This includes engine components, chassis assemblies, and accessory mounting points. By providing a robust connection, the screw helps maintain the structural integrity of these parts, ensuring they function correctly under the stresses of heavy-duty use.

Key Features

The 3020093 Hexagon Head Cap Screw boasts several key features that make it suitable for demanding applications. Its hexagonal head design allows for easy and precise tightening using standard tools. The screw is composed of high-quality materials, typically alloy steel, which offers excellent strength and durability. Additionally, the threading specifications are designed to provide a strong and secure fit, reducing the risk of loosening over time 2.

Benefits

This part offers several benefits that enhance its performance in commercial truck applications. One of the primary advantages is its enhanced fastening strength, which ensures that components remain securely attached even under significant stress. The screw’s design also provides resistance to loosening, which is crucial in dynamic environments where vibrations are common. Furthermore, the ease of installation and removal makes it a practical choice for both initial assembly and maintenance procedures.

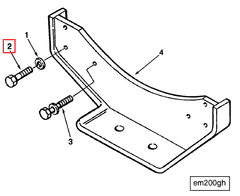

Installation Process

Proper installation of the 3020093 Hexagon Head Cap Screw is crucial to ensure optimal performance. The process involves several steps: First, ensure that the mating threads are clean and free of debris. Next, align the screw with the designated hole and begin threading it by hand to avoid cross-threading. Once the screw is started, use a wrench or socket to tighten it to the specified torque. It is important to use the recommended tools and follow the torque specifications provided by Cummins to achieve the correct tension without over-tightening 3.

Common Applications

This part is utilized in a variety of common applications within commercial trucks. These include fastening engine components such as cylinder heads and valve covers, securing chassis assemblies, and mounting accessories like brackets and panels. Its versatility and reliability make it a preferred choice for these critical applications.

Troubleshooting and Maintenance

In the course of its use, the 3020093 Hexagon Head Cap Screw may encounter issues such as loosening, corrosion, or damage. Troubleshooting these problems involves inspecting the screw and its mating threads for signs of wear or damage. If loosening is detected, re-tightening to the specified torque may resolve the issue. Corrosion can be addressed by cleaning the affected areas and applying a suitable anti-corrosion treatment. Regular maintenance, including periodic checks and re-tightening, can help ensure the screw continues to perform optimally.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its high-quality engines and components. Founded in 1919, Cummins has a long history of innovation and excellence. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts, all designed to meet the rigorous demands of heavy-duty applications. Cummins’ reputation for reliability and performance makes it a trusted name among fleet operators and maintenance professionals 4.

Hexagon Head Cap Screw 3020093 in Cummins Engines

The Hexagon Head Cap Screw 3020093, manufactured by Cummins, is a critical component in various Cummins engine models. This screw is integral to the assembly and maintenance of several engine types, ensuring structural integrity and operational efficiency.

ISM CM570

The ISM CM570 engine benefits from the 3020093 screw in its assembly, providing a reliable fastening solution for various components. This screw’s precision and strength are crucial for maintaining the engine’s structural integrity.

L10 Series

The L10 series, which includes the L10 CELECT, L10 GAS, and L10 MECHANICAL engines, utilizes the 3020093 screw in multiple applications. This screw is essential for securing parts within these engines, ensuring that all components are properly aligned and fastened.

- L10 CELECT: The 3020093 screw is used in the CELECT variant to secure various engine parts, contributing to the engine’s overall performance and reliability.

- L10 GAS: In the L10 GAS engine, this screw is vital for fastening components that are exposed to high temperatures and pressures, ensuring durability and longevity.

- L10 MECHANICAL: The 3020093 screw is also used in the L10 MECHANICAL engine, providing a robust fastening solution for critical engine parts.

M11 Series

The M11 series, comprising the M11 CELECT, M11 CELECT PLUS, and M11 MECHANICAL engines, relies on the 3020093 screw for several key applications. This screw’s precision and strength are essential for maintaining the engine’s structural integrity and performance.

- M11 CELECT: The 3020093 screw is used in the CELECT variant to secure various engine components, ensuring optimal performance and reliability.

- M11 CELECT PLUS: In the M11 CELECT PLUS engine, this screw is crucial for fastening parts that are subject to high stress and wear, contributing to the engine’s durability.

- M11 MECHANICAL: The 3020093 screw is also used in the M11 MECHANICAL engine, providing a reliable fastening solution for critical engine components.

QSM11 CM570

The QSM11 CM570 engine utilizes the 3020093 screw in its assembly, ensuring that all components are securely fastened. This screw’s precision and strength are essential for maintaining the engine’s structural integrity and performance.

Role of Part 3020093 Hexagon Head Cap Screw in Engine Systems

This part is integral to the assembly and securement of various components within engine systems. Its robust design ensures reliable fastening, which is essential for the proper functioning and durability of the engine.

Cooler and Lubricating Oil Systems

In the cooler and lubricating oil systems, the Hexagon Head Cap Screw is used to mount the cooler lubricating oil. This secure attachment ensures that the cooler remains firmly in place, allowing for efficient heat exchange and maintaining the optimal temperature of the lubricating oil. Additionally, it is employed in the engine oil cooler to ensure that the cooler is stably mounted, contributing to consistent engine oil temperature regulation.

Turbocharger and Front Engine Arrangement

For the turbocharger, the Hexagon Head Cap Screw plays a significant role in the front arrangement. It secures the turbocharger to the engine, ensuring that it operates within the designed parameters. This fastening is vital for the turbocharger’s efficiency and longevity, as any movement or misalignment could lead to performance issues or damage.

Gear Housing and Mounting Covers

In the gear housing, the Hexagon Head Cap Screw is used to mount the cover securely. This ensures that the gear housing remains intact, protecting the internal components from contaminants and external damage. Similarly, in the head and oil filter cooler, these screws provide the necessary tension to keep the components in place, ensuring a leak-free seal and efficient operation.

Intake Manifold and Support Structures

The intake manifold mounting adapter relies on the Hexagon Head Cap Screw to ensure a tight and secure fit. This is essential for maintaining the integrity of the air intake system, which directly affects engine performance. Furthermore, in the front engine support and overall engine front support structures, these screws are critical for maintaining the structural integrity and alignment of the engine within the vehicle’s chassis.

EBM-Location and Additional Applications

At the EBM-location (Electric Blower Motor), the Hexagon Head Cap Screw ensures that the motor is securely fastened, allowing for stable operation and preventing vibrations that could affect performance. This screw is also utilized in various other applications throughout the engine system to provide reliable fastening where needed.

Conclusion

Overall, the part 3020093 Hexagon Head Cap Screw is a versatile and essential component in the assembly and maintenance of engine systems, ensuring that all interconnected parts function harmoniously and efficiently.

-

Gifford, Clive. Cars Encyclopedia. DK Publishing, 2014.

↩ -

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩ -

Trzesniowski, Michael. The Complete Vehicle. Springer Nature, 2023.

↩ -

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.