This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3026342 Hexagon Head Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial truck applications. Cummins, a well-established name in the commercial truck industry, is known for its commitment to quality and innovation. This particular screw is significant due to its role in ensuring the structural integrity and reliable operation of truck components.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tightening and loosening using a wrench or socket. The design of the cap screw includes a threaded shank that extends through the components being joined, and a head that distributes the clamping force. Cap screws are commonly used in mechanical assemblies where high strength and secure fastening are required 1.

Role of the 3026342 Hexagon Head Cap Screw in Truck Operation

The 3026342 Hexagon Head Cap Screw plays a specific role in the operation and maintenance of commercial trucks. It is utilized in various truck assemblies, such as engine components, chassis parts, and body panels. Its primary function is to provide a strong and secure connection between different truck components, ensuring that they remain firmly attached under operational stress 2.

Key Features of the 3026342 Hexagon Head Cap Screw

The 3026342 Hexagon Head Cap Screw is defined by several key features that enhance its functionality and durability. These include its material composition, typically a high-strength alloy steel, which provides excellent tensile strength. The screw features a coarse thread type, which allows for quick and secure fastening. The hexagonal head design enables efficient torque application, ensuring a tight and reliable connection 3.

Benefits of Using the 3026342 Hexagon Head Cap Screw

Using the 3026342 Hexagon Head Cap Screw in truck maintenance and repair offers several advantages. Its high-strength material composition ensures enhanced durability and resistance to wear and tear. The screw’s design also provides corrosion resistance, making it suitable for use in various environmental conditions. Additionally, the hexagonal head allows for easy installation and removal, facilitating efficient maintenance procedures 4.

Installation and Usage Guidelines

Proper installation of the 3026342 Hexagon Head Cap Screw involves several steps. Begin by ensuring that the mating surfaces are clean and free of debris. Use a wrench or socket to tighten the screw to the specified torque setting, which can be found in the truck’s maintenance manual. It is important to use the correct tools to avoid damage to the screw or surrounding components. Following these guidelines ensures a secure and lasting connection.

Troubleshooting Common Issues

Common problems associated with Hexagon Head Cap Screws include loosening, corrosion, and thread damage. To address loosening, periodically inspect and re-torque the screws to the manufacturer’s specifications. Corrosion can be mitigated by applying a protective coating or using screws made from corrosion-resistant materials. Thread damage may require replacing the screw or the mating component to restore proper function.

Maintenance Tips

Regular maintenance of the 3026342 Hexagon Head Cap Screw is important for ensuring longevity and reliable performance. This includes periodic inspections to check for signs of wear, corrosion, or loosening. Re-torquing the screws at recommended intervals helps maintain the integrity of the fastening. Keeping the mating surfaces clean and free of contaminants also contributes to the screw’s performance.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, with a history of producing high-quality engine and powertrain components. The company’s product range includes engines, transmissions, and aftermarket parts, all designed to meet the demanding requirements of commercial trucking. Cummins is renowned for its commitment to quality, innovation, and customer satisfaction, making it a trusted name in the industry.

Cummins Hexagon Head Cap Screw 3026342 in Engine Applications

The Cummins Hexagon Head Cap Screw part number 3026342 is a critical component in various engine assemblies. This screw is designed to provide robust fastening capabilities, ensuring secure connections in high-stress environments. Its application spans across multiple engine models, where it plays a pivotal role in maintaining structural integrity and operational efficiency.

L10 MECHANICAL

In the L10 MECHANICAL engine, the Hexagon Head Cap Screw 3026342 is utilized in several key areas. It is often employed in the assembly of engine blocks, where it secures various components together. This screw’s design allows for precise torque application, which is essential for maintaining the alignment and stability of the engine’s internal parts. Additionally, it is used in the mounting of ancillary systems such as the alternator and air intake manifolds, ensuring these systems remain firmly attached under operational conditions.

The use of this screw in the L10 MECHANICAL engine underscores its importance in achieving a reliable and durable engine assembly. Its application in these critical areas highlights the need for high-quality fasteners that can withstand the rigors of engine operation.

Part 3026342 Hexagon Head Cap Screw in Engine Systems

The part 3026342 Hexagon Head Cap Screw is instrumental in securing various components within engine systems, ensuring stability and reliability under operational conditions.

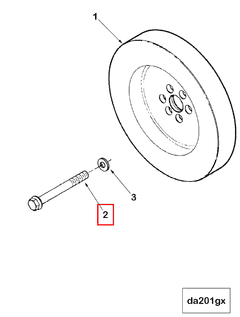

Damper Assembly Integration

In damper assemblies, the Hexagon Head Cap Screw plays a significant role by fastening the damper to the engine block or other structural components. This secure attachment is essential for maintaining the damper’s position and functionality, which in turn helps in absorbing and reducing vibrations generated during engine operation.

Vibration Control

When it comes to vibration management, the Hexagon Head Cap Screw is used to mount vibration dampers and isolators. These components are designed to minimize the transmission of vibrations from the engine to the vehicle’s chassis and other sensitive parts. The screw ensures that the dampers remain firmly in place, allowing them to effectively perform their role in vibration attenuation.

Vibration Damper Attachment

For vibration dampers, the Hexagon Head Cap Screw is employed to connect the damper to the crankshaft or other rotating parts. This connection is vital for the damper to function correctly, absorbing torsional vibrations and preventing them from affecting the engine’s performance and longevity. The screw’s robust design ensures that it can withstand the dynamic loads and stresses encountered in these applications.

Conclusion

The 3026342 Hexagon Head Cap Screw is a vital component in the maintenance and operation of commercial trucks, particularly in engine assemblies. Its high-strength material, efficient design, and reliable performance make it an essential fastener for ensuring the structural integrity and operational efficiency of truck components. Proper installation, regular maintenance, and timely troubleshooting are key to maximizing the benefits of this Cummins part.

-

Alma Hillier, Fundamentals of Motor Vehicle Technology Book 1 6th Edition, Oxford University Press, 2014.

↩ -

Gijs Mom, The Evolution of Automotive Engineering: A Handbook, SAE International, 2023.

↩ -

William B. Ribbens, Understanding Automotive Electronics, Elsevier Science, 2003.

↩ -

Konrad Reif, Automotive Mechatronics, Springer Vieweg, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.