3064109

Hexagon Head Cap Screw

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

Minimum Quantity 4

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3064109 Hexagon Head Cap Screw is a component manufactured by Cummins, a well-established name in the commercial truck industry. This screw is designed for use in commercial trucks, where it plays a role in securing various components together, ensuring the structural integrity and operational efficiency of the vehicle.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tightening and loosening using a wrench or socket. These screws are commonly used in mechanical assemblies to secure components together. They function by threading into a pre-drilled hole, creating a strong and reliable connection that can withstand significant stress and vibration 1.

Purpose of the 3064109 Hexagon Head Cap Screw in Truck Operation

This Cummins part is utilized in various applications within commercial trucks. It is employed in areas where secure fastening is required, such as in the attachment of engine components, chassis parts, and other critical assemblies. Its role is to provide a durable and reliable connection that can endure the harsh conditions and heavy loads typical of commercial trucking operations.

Key Features

The 3064109 features a hexagonal head design, which facilitates easy and precise tightening using standard tools. It is composed of high-quality materials, ensuring durability and resistance to corrosion. The screw’s threading is designed to provide a strong grip, minimizing the risk of loosening over time. Additionally, it may possess unique attributes that enhance its performance in demanding environments 2.

Benefits

Using this Cummins part offers several advantages. It provides improved fastening security, ensuring that components remain firmly attached even under significant stress. Its design resists loosening, maintaining the integrity of the assembly over time. Furthermore, its durability allows it to perform well in the harsh operating conditions typical of commercial trucking, contributing to the longevity and reliability of the vehicle 3.

Installation Considerations

Proper installation of the 3064109 is crucial for optimal performance and safety. It is recommended to follow torque specifications provided by the manufacturer to ensure the screw is tightened to the correct level. Using the appropriate tools, such as a torque wrench, can help achieve the desired tightness. Additionally, taking precautions such as cleaning the mating surfaces and inspecting the screw for any defects before installation can contribute to a secure and lasting connection.

Troubleshooting and Maintenance

Common issues that may arise with the 3064109 include corrosion, stripping, or loosening. Regular inspection and maintenance can help identify and address these issues early. If corrosion is detected, cleaning the affected area and applying a corrosion-resistant coating can prevent further damage. In cases of stripping or loosening, replacing the screw may be necessary to maintain the integrity of the assembly.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s extensive product range and commitment to innovation ensure that components like the 3064109 meet the high standards required for commercial trucking applications.

Hexagon Head Cap Screw 3064109 Compatibility with Cummins Engines

The Cummins Hexagon Head Cap Screw part number 3064109 is a versatile component that fits a variety of Cummins engines. This screw is designed to secure different parts and assemblies within the engine, ensuring structural integrity and proper function. Below is a detailed breakdown of the engines with which this screw is compatible:

G-Series Engines

- G5.9

- G8.3

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

L10 Series Engines

- L10 CELECT

- L10 MECHANICAL

M11 Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

QSK Series Engines

- QSK19 CM850 MCRS

QSM Series Engines

- QSM11 CM570

- QSM11 CM876

QST Series Engines

- QST30 CM2350 T101

- QST30 CM552

QSX Series Engines

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

This screw is engineered to meet the stringent requirements of Cummins engines, ensuring durability and reliability in various operating conditions. It is essential for maintaining the alignment and securing the components within these engines, contributing to their overall performance and longevity.

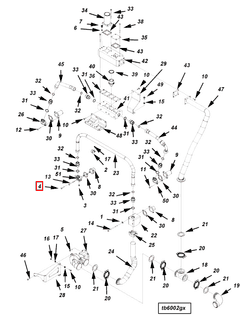

Role of Part 3064109 Hexagon Head Cap Screw in Engine Systems

The 3064109 is integral to the assembly and operation of various engine components. Its robust design ensures secure fastening, which is essential for maintaining the integrity and efficiency of the engine system.

Accessories and Electric Starting

In the context of accessories and electric starting systems, the Hexagon Head Cap Screw is used to mount and secure components such as the starter motor and related electrical connections. This ensures that the electric starting system remains stable and functions correctly during engine start-up.

Air Compressor Upfit Kit and Brackets

For the air compressor upfit kit, this screw plays a significant role in attaching the compressor to its mounting bracket. It ensures that the compressor is firmly secured, which is vital for consistent air pressure delivery and overall system reliability.

Fuel Governor and Oil Fill Arrangement

In the fuel governor arrangement, the screw is employed to fasten the governor housing and linkages, ensuring precise fuel delivery and engine performance. Similarly, in the oil fill arrangement, it secures the oil fill cap and associated components, maintaining a sealed system for optimal lubrication.

Breather and Crankcase Components

The breather and crankcase components rely on the Hexagon Head Cap Screw to secure breather tubes and crankcase covers. This is important for managing pressure within the crankcase and ensuring that contaminants are effectively vented from the engine.

Compressor and Air Connection

For the air compressor and its connections, the screw is used to attach air lines and fittings, guaranteeing a leak-free system that delivers compressed air efficiently to various engine components.

Exhaust Outlet and Coupling

In the exhaust system, the screw secures the exhaust outlet and coupling components, ensuring that the exhaust gases are directed away from the engine compartment safely and efficiently.

Fuel Pump and Drive

The fuel pump and its drive mechanism utilize the screw to attach the pump to the engine block and secure drive components, ensuring consistent fuel supply under varying engine loads.

Engine Control Module and Governor

The engine control module (ECM) and fuel governor benefit from the screw’s secure fastening capabilities, ensuring that these critical control units remain firmly in place and operate within specified parameters.

Idler Top Level Assembly Pulley

In the idler top-level assembly pulley system, the screw is used to attach the pulley to its bracket, ensuring smooth belt tension and reliable accessory drive operation.

Mounting Air Compressor and Alternator

For mounting the air compressor and alternator, the screw provides the necessary strength to withstand vibrational forces, ensuring these components remain operational and efficiently contribute to engine performance.

Oil Pan and Plumbing Components

The oil pan and various plumbing components, such as the aftercooler water and crankcase breather systems, rely on the screw to secure fittings and ensure leak-free operation, which is essential for maintaining engine lubrication and cooling.

Turbocharger, Raw Water Pump, and Auxiliary Cooling System

In the turbocharger, raw water pump, and auxiliary cooling system, the screw is used to attach and secure critical components, ensuring these systems operate efficiently and contribute to overall engine performance and longevity.

Thermostat Housing

Finally, in the thermostat housing, the screw ensures that the housing is securely attached to the engine, maintaining proper coolant flow and temperature regulation.

Conclusion

The 3064109 Hexagon Head Cap Screw is a critical component in the maintenance and operation of Cummins engines. Its design and features ensure secure fastening, durability, and resistance to corrosion, contributing to the overall performance and longevity of commercial trucks. Proper installation, regular maintenance, and understanding its role in various engine systems are essential for maximizing the benefits of this Cummins part.

-

Van Gelder, Kirk T. Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning, 2018.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Robinson, Alan, and Andrew Livesey. The Repair of Vehicle Bodies Fifth Edition. Elsevier, 2006.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.