This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Hexagon Head Cap Screw is a fundamental component in the realm of commercial trucks, providing secure fastening solutions that are vital for the integrity and performance of various truck systems. Manufactured by Cummins, a renowned name in the commercial truck industry, the 3064115 Hexagon Head Cap Screw is designed to meet the rigorous demands of heavy-duty applications. This overview delves into the specifics of this screw, its functionality, and the manufacturer behind it.

Basic Concepts of Hexagon Head Cap Screw

A Hexagon Head Cap Screw is characterized by its hexagonal head, which allows for efficient tightening and loosening using a wrench or socket. This design ensures a firm grip, reducing the risk of slippage during installation. Within mechanical systems, these screws play a role in securing components together, ensuring structural integrity and proper function. The cap at the end of the screw covers and protects the fastener, enhancing its durability and resistance to environmental factors 1.

Purpose of the 3064115 Hexagon Head Cap Screw in Truck Operation

The 3064115 Hexagon Head Cap Screw is integral to the operation and maintenance of commercial trucks. It is used in various applications where secure fastening is required, such as in engine components, chassis assemblies, and other critical areas. By providing a reliable connection, this screw helps maintain the structural integrity and performance of the truck, ensuring that components remain securely in place under varying operational conditions.

Key Features of the 3064115 Hexagon Head Cap Screw

The 3064115 Hexagon Head Cap Screw is engineered with specific attributes that make it suitable for heavy-duty applications. It is constructed from high-strength materials, ensuring durability under significant stress. The threading is designed to provide a strong grip, preventing loosening over time. Additionally, the hexagonal head design facilitates easy installation and removal, enhancing efficiency during maintenance procedures.

Benefits of Using the 3064115 Hexagon Head Cap Screw

Utilizing the 3064115 Hexagon Head Cap Screw offers several advantages. Its robust construction contributes to the longevity of the fastening, reducing the need for frequent replacements. The ease of installation, thanks to its hexagonal head, allows for quick and efficient assembly. Moreover, the screw’s design minimizes the risk of loosening, ensuring that components remain securely fastened throughout the truck’s operation.

Installation and Usage Guidelines

Proper installation of the 3064115 Hexagon Head Cap Screw is vital for its effectiveness. Begin by ensuring the mating surfaces are clean and free of debris. Use the appropriate wrench or socket to tighten the screw to the specified torque, which can be found in the manufacturer’s guidelines. It is important to avoid over-tightening, as this can damage the screw or the components being fastened. Recommended tools include a torque wrench for precise tightening and a socket set for efficient handling.

Troubleshooting Common Issues

Common issues with Hexagon Head Cap Screws include loosening, corrosion, and damage. To address loosening, ensure the screw is tightened to the correct torque during installation. Corrosion can be mitigated by using screws made from corrosion-resistant materials and applying a protective coating if necessary. Damage to the screw or surrounding components may require replacement or repair, following proper maintenance procedures.

Maintenance Tips

Regular inspection and maintenance of the 3064115 Hexagon Head Cap Screw are important for ensuring its longevity and performance. Check for signs of loosening, corrosion, or damage during routine maintenance checks. Re-tighten screws as needed and replace any that show signs of wear or failure. Keeping the screw and surrounding areas clean will also help prevent issues and ensure reliable operation.

Cummins: Manufacturer Overview

Cummins is a leading manufacturer in the commercial truck industry, known for its high-quality engines and components. With a rich history of innovation and excellence, Cummins offers a wide range of products designed to meet the demanding requirements of heavy-duty applications. The company’s reputation for reliability and performance makes it a trusted choice for truck operators and maintenance professionals alike 2.

Hexagon Head Cap Screw 3064115 in Cummins Engines

The Cummins Hexagon Head Cap Screw part number 3064115 is a versatile component utilized across various Cummins engine models. This screw is integral in securing different parts within the engine assembly, ensuring structural integrity and operational efficiency.

G8.3 Series

In the G8.3 series, the 3064115 screw is employed in several applications, including securing the engine’s mounting brackets and other critical components. Its robust design ensures that these parts remain firmly in place under varying operational conditions.

G855 Series

Similarly, in the G855 series, this screw is used to fasten various engine components, ensuring that the engine’s internal parts are securely held together. This is crucial for maintaining the engine’s performance and longevity.

ISBE CM800

The ISBE CM800 engine utilizes the 3064115 screw in its assembly, particularly in securing the engine’s mounting points and other critical fixtures. This ensures that the engine operates smoothly and efficiently.

ISC CM554 and ISL CM554

Both the ISC CM554 and ISL CM554 engines incorporate the 3064115 screw in their design. This screw is used to fasten various components, ensuring that the engine’s internal parts are securely held together, contributing to the engine’s overall performance.

ISM CM570 and ISM CM570/870

The ISM CM570 and ISM CM570/870 engines also use the 3064115 screw. This screw is crucial in securing the engine’s mounting brackets and other critical components, ensuring that the engine operates reliably and efficiently.

ISM11 CM876 SN

In the ISM11 CM876 SN engine, the 3064115 screw is used to fasten various parts, ensuring that the engine’s internal components are securely held together. This is essential for maintaining the engine’s performance and durability.

L10 Series

The L10 series, which includes the L10 CELECT, L10 GAS, and L10 MECHANICAL engines, utilizes the 3064115 screw in its assembly. This screw is used to secure the engine’s mounting points and other critical fixtures, ensuring that the engine operates smoothly and efficiently.

M11 Series

The M11 series, including the M11 CELECT, M11 CELECT PLUS, and M11 MECHANICAL engines, also incorporates the 3064115 screw. This screw is used to fasten various components, ensuring that the engine’s internal parts are securely held together, contributing to the engine’s overall performance.

QSC8.3 Series

In the QSC8.3 series, the 3064115 screw is used to secure the engine’s mounting brackets and other critical components. Its robust design ensures that these parts remain firmly in place under varying operational conditions.

QSC8.3 CM850 (CM2850) and QSL9 CM554

The QSC8.3 CM850 (CM2850) and QSL9 CM554 engines also utilize the 3064115 screw. This screw is crucial in securing the engine’s mounting points and other critical fixtures, ensuring that the engine operates reliably and efficiently.

QSM11 CM570

The QSM11 CM570 engine incorporates the 3064115 screw in its design. This screw is used to fasten various components, ensuring that the engine’s internal parts are securely held together, contributing to the engine’s overall performance.

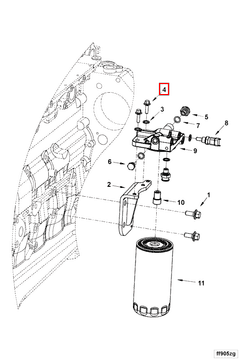

Component Usage of 3064115 Hexagon Head Cap Screw

The 3064115 Hexagon Head Cap Screw is integral to the assembly and maintenance of various engine components. Its robust design ensures secure fastening, which is essential for the reliable operation of the following components:

- Belt Tensioner Kit: The screw is used to secure the tensioner, ensuring the proper tension on the belts that drive accessories such as the alternator and water pump.

- Cam Housing Module: It plays a role in fastening the module, which houses the camshaft and related components, ensuring precise valve timing.

- Air Cleaner: Secures the air cleaner housing, maintaining the integrity of the air intake system and ensuring clean air flow to the engine.

- Air Intake Connection: Fastens components within the air intake system, ensuring a sealed and efficient airflow path to the engine.

- Crankshaft Seal Replacer: Used during the replacement process to secure the tool, allowing for the safe and effective replacement of crankshaft seals.

- Engine Mounting Plate: Secures the mounting plate, which is critical for the stable attachment of the engine to the vehicle’s frame.

- Heat Exchanger: Fastens components of the heat exchanger, ensuring efficient heat transfer and maintaining the cooling system’s performance.

- Fuel Filter: Secures the fuel filter housing, ensuring that the filter remains in place and functions correctly to remove contaminants from the fuel.

- Fuel Filter Head: Used to fasten the head of the fuel filter, ensuring a secure connection and preventing leaks.

- Fuel Pump: Secures components of the fuel pump assembly, ensuring it remains firmly in place within the fuel tank.

- Fuel Control Module: Fastens the module, which regulates fuel delivery to the engine, ensuring optimal performance and efficiency.

- Alternator Mounting: Secures the alternator to the engine, ensuring it operates correctly to charge the battery and power electrical systems.

- Refrigerant Compressor Mounting: Used to fasten the compressor, which is vital for the operation of the vehicle’s air conditioning system.

- Auxiliary Pump: Secures auxiliary pumps, which may be used for additional fluid circulation needs within the engine system.

Conclusion

The 3064115 Hexagon Head Cap Screw by Cummins is a critical component in the assembly and maintenance of commercial truck engines. Its robust design, ease of installation, and reliable performance make it an essential part for securing various engine components. Proper installation, regular maintenance, and understanding its applications across different Cummins engine models ensure the longevity and efficiency of the truck’s operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.