This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Head Cap Screw, specifically part #3076314 manufactured by Cummins, plays a significant role in commercial truck applications. This screw is integral to the fastening systems used in various truck components, ensuring the secure assembly of parts that are subject to rigorous operational conditions.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient torque application using common tools such as wrenches or sockets. The hexagonal design prevents the head from rounding, which enhances the screw’s durability and reliability in fastening applications. Mechanically, these screws function by converting rotational force into linear force, securing components together under tension 1.

Role of the 3076314 Hexagon Head Cap Screw in Truck Operation

This Cummins part is utilized in various applications within commercial trucks. It is commonly found in engine components, chassis assemblies, and other critical systems where secure fastening is required. This screw contributes to the overall functionality and reliability of the vehicle by ensuring that components remain firmly attached, even under the stress of heavy-duty operations.

Key Features

The 3076314 Hexagon Head Cap Screw is crafted from high-quality materials, typically featuring a robust thread type designed for heavy-duty applications. It may include special coatings or treatments to enhance corrosion resistance and improve performance in demanding environments. These features collectively contribute to the screw’s ability to maintain secure fastenings over extended periods, even in harsh conditions.

Benefits

Using the 3076314 Hexagon Head Cap Screw offers several advantages, including improved fastening security, enhanced corrosion resistance, and ease of installation and removal. These benefits contribute to the efficiency and safety of truck operations by ensuring that critical components remain securely fastened, reducing the risk of failure due to loosening or corrosion.

Troubleshooting and Maintenance

Common issues with Hexagon Head Cap Screws may include loosening over time or corrosion in exposed applications. Troubleshooting these issues involves checking for proper torque settings and ensuring that screws are not overtightened, which can lead to stripping. Regular maintenance practices, such as periodic inspection and re-torquing, help ensure the longevity and reliability of the 3076314 screw. Additionally, applying appropriate lubricants or anti-seize compounds can prevent seizing and facilitate easier removal when necessary 2.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel engines, natural gas engines, and related technologies. With a strong commitment to quality and innovation, Cummins has established itself as a trusted name in the commercial vehicle industry, providing reliable components that enhance the performance and durability of trucks and other heavy-duty equipment.

Hexagon Head Cap Screw (Part 3076314) in Cummins Engines

The Hexagon Head Cap Screw, part number 3076314, manufactured by Cummins, is a critical component in various Cummins engine models. This screw is designed to provide secure fastening in applications where high strength and durability are essential.

G855 and NH/NT 855 Engines

In the G855 and NH/NT 855 engines, the Hexagon Head Cap Screw is utilized for fastening various parts of the engine’s internal and external structures. Its robust design ensures that it can withstand the high stresses and vibrations typical in these engine models.

N14 CELECT and N14 CELECT PLUS Engines

For the N14 CELECT and N14 CELECT PLUS engines, the Hexagon Head Cap Screw is integral in maintaining the integrity of the engine’s components. These engines, known for their reliability and performance, benefit from the precision and strength offered by this screw in securing critical engine parts.

N14 MECHANICAL Engine

In the N14 MECHANICAL engine, the Hexagon Head Cap Screw is used extensively for fastening various engine components. Its design ensures that it can handle the mechanical stresses encountered in this engine model, contributing to the overall durability and performance of the engine.

QSK19 CM850 MCRS Engine

The QSK19 CM850 MCRS engine also relies on the Hexagon Head Cap Screw for securing numerous engine parts. This screw’s ability to provide a tight and secure fit is crucial in maintaining the engine’s operational efficiency and longevity.

Role of Part 3076314 Hexagon Head Cap Screw in Engine Systems

The Part 3076314 Hexagon Head Cap Screw is integral to the assembly and securement of various components within engine systems. Its application spans across multiple areas, ensuring the stability and functionality of the engine’s cooling and support structures.

Accessory Kit

Within the accessory kit, the Hexagon Head Cap Screw is utilized to fasten smaller components that are essential for the engine’s operation. This includes securing sensors, small brackets, and other accessories that contribute to the engine’s performance and efficiency.

Brackets

The screw plays a significant role in attaching brackets that support various engine components. Whether it’s the bracket for the fan & support TCC or the fan hub, these brackets must be securely fastened to withstand the vibrations and stresses of engine operation.

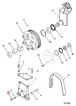

Fan & Support TCC

In the fan & support TCC assembly, the Hexagon Head Cap Screw is employed to ensure that the fan and its support structure are firmly attached. This is vital for the efficient operation of the cooling system, as any looseness could lead to inefficient cooling or even damage to the fan blades.

Fan Hub and Damper

The fan hub, which is central to the fan’s operation, relies on the Hexagon Head Cap Screw for secure attachment to the damper. This connection is essential for the smooth operation of the fan, reducing vibrations and ensuring consistent airflow through the radiator cooling system.

Fan Drive and Arrangements

For the fan drive and its arrangements, the screw is used to secure the drive mechanism to the engine. This is important for the transmission of power to the fan, ensuring it operates at the correct speed to maintain optimal engine temperature.

Fan Brace Kit and Support

The fan brace kit and its support structures are critical for maintaining the alignment and stability of the fan. The Hexagon Head Cap Screw is used throughout these assemblies to provide the necessary strength and durability.

Radiator Cooling System

In the radiator cooling system, the screw is used to attach the fan bracket and its support to the radiator. This ensures that the fan is positioned correctly to draw air through the radiator, facilitating effective heat exchange and engine cooling.

Torque Converter Cooling

Lastly, in the torque converter cooling setup, the Hexagon Head Cap Screw is used to secure components that are part of the cooling circuit for the torque converter. This is essential for maintaining the converter’s temperature within operational limits, ensuring smooth and efficient power transmission.

Throughout these applications, the Part 3076314 Hexagon Head Cap Screw demonstrates its versatility and importance in maintaining the integrity and performance of engine systems.

Conclusion

The 3076314 Hexagon Head Cap Screw by Cummins is a vital component in the assembly and maintenance of commercial truck engines and components. Its robust design, high-quality materials, and versatile applications make it an essential part in ensuring the secure fastening of various engine components, contributing to the overall reliability and performance of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.