This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Head Cap Screw, specifically Part #3165930 by Cummins, is a vital component in the realm of commercial trucks. Cummins, a renowned manufacturer in the automotive industry, produces this screw which is integral to the fastening systems in trucks. This overview will delve into the specifics of the Hexagon Head Cap Screw, its design, functionality, and the role it plays in the maintenance and operation of commercial trucks.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tightening and loosening using a wrench or socket. The design of the screw ensures a secure fit, minimizing the risk of slippage during installation. In fastening applications, these screws are used to join components securely, playing a role in maintaining the structural integrity of various parts within a vehicle 1.

Purpose of the 3165930 Hexagon Head Cap Screw in Truck Operations

The 3165930 Hexagon Head Cap Screw by Cummins is designed to meet the demanding requirements of commercial truck operations. It is utilized in various applications where secure fastening is required, such as in the attachment of body panels, engine components, and other critical parts. The screw’s design ensures that it can withstand the vibrations and stresses encountered in heavy-duty truck environments, contributing to the overall reliability and safety of the vehicle 2.

Key Features of the 3165930 Hexagon Head Cap Screw

The 3165930 Hexagon Head Cap Screw boasts several features that make it suitable for heavy-duty applications. Its hexagonal head provides a firm grip for tools, facilitating easy installation and removal. The screw is crafted from high-quality materials, ensuring durability and resistance to corrosion. Additionally, its design includes threading that engages effectively with mating components, enhancing the security of the fastening 3.

Benefits of Using the 3165930 Hexagon Head Cap Screw

Utilizing the 3165930 Hexagon Head Cap Screw offers several advantages. Its robust construction contributes to the longevity of the fastening, reducing the need for frequent replacements. The screw’s reliability is enhanced by its resistance to wear and corrosion, which is particularly beneficial in the harsh environments typical of commercial truck operations. Furthermore, the ease of installation and removal provided by its hexagonal head simplifies maintenance procedures.

Installation Procedures

To ensure optimal performance and safety, the 3165930 Hexagon Head Cap Screw should be installed following specific procedures. Begin by selecting the appropriate tool for the screw’s hexagonal head. Align the screw with the designated hole and start threading it in by hand to avoid cross-threading. Once the screw is started, use the tool to tighten it to the manufacturer’s specified torque settings. This ensures that the screw is secure without being overtightened, which could damage the screw or the component it is fastening.

Troubleshooting Common Issues

Common issues with Hexagon Head Cap Screws may include difficulty in tightening, slippage, or corrosion. If tightening is problematic, ensure that the screw is correctly aligned and that the mating surface is clean and free of debris. Slippage can often be addressed by using a wrench or socket that fits snugly on the hexagonal head. Corrosion may be prevented by applying a suitable anti-corrosive treatment to the screw before installation, especially in environments where exposure to moisture is likely.

Maintenance Tips

Regular maintenance of the 3165930 Hexagon Head Cap Screw is important to prolong its lifespan and ensure continued efficiency. Inspect the screw periodically for signs of wear, corrosion, or loosening. If any issues are detected, address them promptly to prevent further damage. Cleaning the screw and its surrounding area can also help maintain its condition. Additionally, ensuring that the screw is tightened to the correct torque specification during maintenance checks will help preserve the integrity of the fastening.

Cummins: A Brief Overview

Cummins is a well-established manufacturer with a strong reputation in the automotive industry. The company has a history of producing high-quality components, including the 3165930 Hexagon Head Cap Screw. Cummins’ commitment to quality is evident in the design and manufacturing processes of their products, which are engineered to meet the rigorous demands of commercial truck applications. The company’s dedication to innovation and customer satisfaction underscores its position as a trusted provider of automotive components.

Hexagon Head Cap Screw 3165930 in Cummins Engines

The Cummins Hexagon Head Cap Screw part number 3165930 is a critical component in various Cummins engine models. This screw is integral to the assembly and maintenance of these engines, ensuring structural integrity and operational efficiency.

K-Series Engines

In the K-Series engines, specifically the K19, K38, and K50, the 3165930 screw is used in several key applications. These engines, known for their robust design and reliability, require precise fastening to maintain the alignment and stability of various components. The screw’s hexagonal head provides a secure grip for wrenches, facilitating easy installation and removal during maintenance.

N-Series Engines

For the N-Series engines, including the N14 MECHANICAL, the 3165930 screw plays a vital role in securing different parts. This engine, recognized for its durability and performance, relies on the screw to hold together components that are subjected to significant stress and vibration. The screw’s design ensures that these parts remain tightly fastened, contributing to the engine’s overall longevity and efficiency.

QSK Engines

In the QSK engines, such as the QSK19 CM850 MCRS and QSK38 CM850 MCRS, the 3165930 screw is used in various critical applications. These engines are designed for heavy-duty operations and require reliable fastening solutions to maintain their structural integrity. The screw’s high-strength properties make it suitable for the demanding conditions these engines operate under.

QSNT Engines

The QSNT14 CM876 N102 engine also utilizes the 3165930 screw in its assembly. This engine, known for its versatility and performance, depends on the screw to secure components that are essential for its operation. The screw’s design ensures that these parts remain securely fastened, contributing to the engine’s reliability and efficiency.

Overall, the Cummins Hexagon Head Cap Screw part number 3165930 is a vital component across various Cummins engine models, ensuring the secure assembly and maintenance of critical parts.

Role of Part 3165930 Hexagon Head Cap Screw in Engine Systems

In the intricate assembly of engine systems, the part 3165930 Hexagon Head Cap Screw serves as a fundamental fastening component. Its application spans across various engine components, ensuring secure and reliable connections.

Accessories

Within the realm of engine accessories, the Hexagon Head Cap Screw is instrumental in attaching components such as sensors, gauges, and control modules. These accessories rely on the screw’s robust fastening capability to maintain their position and functionality amidst the dynamic environment of the engine compartment.

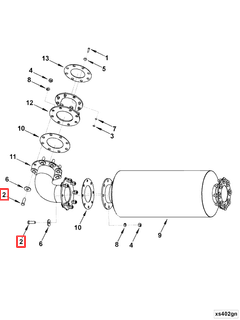

Exhaust Outlet

The exhaust outlet, a vital component responsible for expelling exhaust gases from the engine, necessitates precise assembly. The Hexagon Head Cap Screw plays a pivotal role in securing the exhaust outlet to the engine block or manifold, ensuring a leak-free seal and optimal exhaust flow.

Connection

In the intricate network of engine connections, the Hexagon Head Cap Screw facilitates the secure attachment of various components. Whether connecting intake manifolds, fuel injectors, or wiring harnesses, this screw ensures stability and integrity in the engine’s complex assembly.

Exhaust Accessory Mounting

Exhaust accessories, such as catalytic converters and resonators, require sturdy mounting solutions to withstand the rigors of engine operation. The Hexagon Head Cap Screw provides reliable fastening for these accessories, ensuring they remain securely in place and function effectively within the exhaust system.

Muffler

The muffler, tasked with reducing engine noise and controlling exhaust emissions, relies on the Hexagon Head Cap Screw for secure attachment to the exhaust system. This screw ensures the muffler remains firmly in position, contributing to the overall efficiency and performance of the exhaust system.

Conclusion

In summary, the part 3165930 Hexagon Head Cap Screw plays a vital role in the assembly and functionality of various engine components, including accessories, exhaust outlets, connections, exhaust accessory mountings, and mufflers. Its reliable fastening capability ensures the integrity and performance of these critical engine systems.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩ -

Schneider, W.-H. (2016). Pistons and Engine Testing. Springer Nature.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.