This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3600815 Hexagon Head Cap Screw is a specialized fastener designed for use in commercial trucks. It is integral to the maintenance and operation of these vehicles, ensuring that various components remain securely fastened under demanding conditions. This screw is part of a broader range of high-quality fasteners that Cummins offers, aimed at enhancing the reliability and performance of commercial trucks.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tightening and loosening using standard tools such as wrenches or sockets. The design of the cap screw includes a threaded shank that engages with internal threads in the mating part, providing a strong and secure connection. Cap screws are commonly used in mechanical assemblies where high strength and resistance to loosening are required 1.

Purpose of the 3600815 Hexagon Head Cap Screw in Truck Operation

The 3600815 Hexagon Head Cap Screw plays a specific role in the operation and maintenance of commercial trucks. It is utilized in various truck assemblies where secure fastening is crucial. Common applications include fastening engine components, securing chassis parts, and attaching body panels. The screw’s design ensures that these critical connections remain intact, even under the vibrations and stresses encountered during truck operation 2.

Key Features of the 3600815 Hexagon Head Cap Screw

The 3600815 Hexagon Head Cap Screw boasts several key features that contribute to its functionality and durability. It is made from high-strength materials, typically alloy steel, which provides excellent tensile strength and resistance to wear. The screw features a coarse thread type, which allows for quick and easy installation while maintaining a strong grip. The hexagonal head design facilitates the use of standard tools, ensuring convenient and efficient fastening. Additionally, the screw is coated to enhance corrosion resistance, prolonging its service life in various environmental conditions 3.

Benefits of Using the 3600815 Hexagon Head Cap Screw

Using the 3600815 Hexagon Head Cap Screw in truck maintenance offers several advantages. The high-strength material and coarse thread type provide improved fastening security, reducing the risk of loosening over time. The hexagonal head allows for easy installation and removal using standard tools, enhancing efficiency during maintenance procedures. The corrosion-resistant coating ensures that the screw remains reliable in diverse operating environments, contributing to the overall durability and performance of the truck 4.

Installation Guidelines

Proper installation of the 3600815 Hexagon Head Cap Screw is vital to ensure secure fastening. Begin by cleaning the mating threads and surfaces to remove any debris or contaminants. Use a torque wrench to tighten the screw to the specified torque value, which ensures that the fastener is adequately secured without over-tightening, which could lead to damage. It is also important to follow best practices, such as using a thread lubricant if recommended, to facilitate smooth installation and reduce the risk of galling or seizing 5.

Troubleshooting and Maintenance

Common issues with Hexagon Head Cap Screws include loosening over time due to vibrations or inadequate torque, and corrosion in harsh environments. To troubleshoot these issues, regularly inspect the screws for signs of wear or corrosion. If loosening is detected, re-tighten the screw to the specified torque value. In cases of severe corrosion, replacement of the screw may be necessary. Maintenance tips include applying a corrosion-resistant coating periodically and ensuring that all fasteners are tightened to the correct specifications during routine inspections 6.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company is committed to quality and innovation, continually developing advanced components and solutions to enhance the performance and reliability of commercial vehicles. Cummins’ dedication to excellence is evident in its comprehensive range of truck components, including high-quality fasteners like the 3600815 Hexagon Head Cap Screw.

Cummins Engine Compatibility with Hexagon Head Cap Screw Part 3600815

The Cummins Hexagon Head Cap Screw part number 3600815 is a versatile component designed to fit a wide range of Cummins engines. This part is integral in securing various engine components, ensuring stability and reliability across multiple engine models.

Cummins Diesel Engines

- 4B3.9

- 6B5.9

- 6C8.3

- G8.3

- G855

- ISC CM554

- ISL CM554

- QSB5.9 44 CM550

- QSC8.3 CM554

These engines, primarily used in heavy-duty applications, benefit from the robust design of the 3600815 screw. Its application in these engines ensures that critical components are securely fastened, contributing to the overall performance and longevity of the engine.

Cummins Natural Gas Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

The Hexagon Head Cap Screw part number 3600815 is also compatible with Cummins’ natural gas engines. These engines, designed for cleaner and more efficient operation, rely on precise and reliable fastening solutions to maintain their operational integrity.

Cummins Medium-Duty Engines

- N14 CELECT

- N14 G

- N14 MECHANICAL

In the medium-duty engine lineup, the 3600815 screw is used to secure various components, ensuring that these engines perform reliably under demanding conditions.

Cummins Industrial Engines

- KTA19GC CM558

- V903

For industrial applications, the 3600815 screw is essential in maintaining the structural integrity of the KTA19GC CM558 and V903 engines. Its use in these engines ensures that they can withstand the rigors of continuous operation in demanding industrial environments.

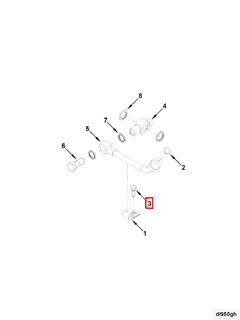

Role of Part 3600815 Hexagon Head Cap Screw in Engine Systems

The part 3600815 Hexagon Head Cap Screw is integral to the assembly and securement of various components within engine systems. Its application spans across multiple subsystems, ensuring the stability and functionality of each part.

In the Air Heater Starting system, this screw is used to fasten components that facilitate the preheating of air before it enters the combustion chamber, enhancing engine start-up in cold conditions.

For the Air Transfer Mounting Tube, the screw plays a role in securing the tube to the engine frame, ensuring a stable and leak-free connection for the transfer of air.

In the Turbocharger arrangement, the screw is employed to mount the turbocharger to the engine, ensuring it remains securely in place during operation.

The BRKT to Plate MTG (Bracket to Plate Mounting) utilizes this screw to connect brackets to plates, providing a sturdy foundation for various engine components.

Within the Dust Seal application, the screw helps in mounting the dust seal, which is essential for preventing contaminants from entering sensitive engine parts.

For the EBM-Location (Electrical Mounting Bracket), the screw is critical in securing electrical components to the engine, ensuring they remain in place and function correctly.

In the Engine Cooling Fan Shroud, the screw is used to attach the shroud to the engine, aiding in the efficient dissipation of heat.

The Engine Instrumentation system benefits from this screw by securing gauges and sensors to the engine, allowing for accurate monitoring of engine performance.

In the Exhaust Cooler Leak Test Kit, the screw is utilized to mount components that are essential for testing the integrity of the exhaust cooler.

For the Filter, Oil Bypass, the screw is instrumental in securing the filter housing, ensuring the bypass system functions correctly.

In the Guard, Dumper & Sea Wtr PU (Sea Water Pump), the screw is used to mount the guard, protecting the pump from debris and ensuring its longevity.

The Hourmeter and Hourmeter Mounting rely on this screw to securely attach the hourmeter to the engine, providing accurate operational hours data.

In the Lever, Throttle, the screw is used to mount the throttle lever, ensuring precise control over engine speed.

For the Module, Engine Control, the screw is essential in securing the control module to the engine, facilitating efficient engine management.

In the Pace Control system, the screw is used to mount components that regulate the engine’s pace, ensuring smooth operation.

The Piston Assembly Remover utilizes this screw to secure components during the removal process, ensuring safety and efficiency.

In the Pump, Raw Water, the screw is used to mount the pump, ensuring it remains securely in place during operation.

For the System, Electronic Engine Control, the screw is critical in securing electronic components, ensuring reliable engine control.

In the Turbocharger Location and Turbocharger Mounting, the screw is used to secure the turbocharger to the engine, ensuring it operates efficiently.

The Turbocharger Mounting Kit relies on this screw to assemble and secure the turbocharger to the engine.

In the Valve, Pressure Regulator, the screw is used to mount the valve, ensuring it regulates pressure effectively.

Conclusion

The Cummins 3600815 Hexagon Head Cap Screw is a critical component in the maintenance and operation of commercial trucks. Its high-strength material, coarse thread type, and corrosion-resistant coating make it an ideal choice for securing various engine components across a wide range of Cummins engines. Proper installation and regular maintenance ensure the longevity and reliability of this fastener, contributing to the overall performance and durability of commercial vehicles.

-

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Department of Energy. (2015). Department of Energy Fundamentals Handbook. Department of Energy.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4332644.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4332644.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.