This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Hexagon Head Cap Screw, specifically part number 3863364 manufactured by Cummins, is a critical component in commercial truck maintenance. Cummins, a well-established industry leader, ensures that this part meets rigorous standards for durability and performance, contributing to the structural integrity and operational efficiency of trucks 1.

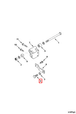

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is distinguished by its hexagonal head, which allows for efficient torque application using a wrench or socket. This design ensures secure fastening in various mechanical systems. The screw’s threaded shaft engages with corresponding threads in the material it is securing, creating a robust and reliable connection 2.

Purpose of the 3863364 Hexagon Head Cap Screw in Truck Operation

This Cummins part is essential in the operation and maintenance of commercial trucks. It is used in applications requiring secure fastening, such as attaching panels, securing engine components, and joining structural elements. The screw provides a strong, durable connection that withstands the rigors of truck operation, ensuring components remain securely in place 3.

Key Features of the 3863364 Hexagon Head Cap Screw

The 3863364 is constructed from high-quality materials, ensuring durability and resistance to wear. It features a specific thread type for optimal engagement with the material it is securing. The hexagonal head design allows for easy and efficient torque application, facilitating quick and secure fastening.

Benefits of Using the 3863364 Hexagon Head Cap Screw

Utilizing this part offers several advantages. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. The ease of installation, thanks to its hexagonal head, allows for efficient assembly and disassembly. Additionally, its design resists loosening over time, maintaining a secure connection under operational stresses.

Installation and Usage Guidelines

To ensure optimal performance and longevity, the 3863364 should be installed according to specific guidelines. Begin by ensuring the mating surfaces are clean and free of debris. Apply the screw using a wrench or socket, applying even torque to avoid cross-threading. It is important to achieve the recommended torque specification to ensure a secure connection without over-tightening, which could damage the screw or the material.

Troubleshooting Common Issues

Common issues with Hexagon Head Cap Screws may include loosening over time or difficulty in removal. To address loosening, ensure the screw is properly torqued during installation and consider using a thread locker for additional security. If removal is difficult, applying penetrating oil and allowing it to dwell can help loosen the screw. In cases of stripped threads, it may be necessary to repair or replace the damaged component.

Maintenance Tips

Regular maintenance can prolong the life of the 3863364 and ensure continued reliable performance. Inspect screws periodically for signs of wear or loosening. Re-torque screws as necessary to maintain secure connections. Keep mating surfaces clean to prevent corrosion, which can weaken the screw’s hold. Additionally, protect screws from environmental factors that may accelerate wear, such as moisture or extreme temperatures.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality, innovation, and reliability in the commercial truck industry. The company’s extensive product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial applications.

Compatibility of 3863364 with Cummins Engines

The 3863364, manufactured by Cummins, is compatible with a variety of Cummins engines. This screw is designed to provide a secure fastening solution, ensuring that engine components remain tightly secured during operation. Below is a detailed breakdown of the engines with which this part is compatible:

Cummins 4B3.9 and 6B5.9 Engines

The 4B3.9 and 6B5.9 engines, known for their reliability and performance, utilize the 3863364 in several critical applications. These engines, often found in medium-duty trucks, benefit from the screw’s ability to withstand high torque and maintain a tight seal, ensuring optimal engine performance.

Cummins 6C8.3 Engines

The 6C8.3 engine, a part of Cummins’ range of medium-duty diesel engines, also incorporates the 3863364. This engine, favored for its balance of power and efficiency, relies on the screw for securing various engine components, ensuring longevity and reliability.

Cummins ISC CM2150 and ISL CM2150 Engines

Both the ISC CM2150 and ISL CM2150 engines, which are widely used in heavy-duty applications, feature the 3863364. These engines benefit from the screw’s robust design, which helps maintain the integrity of engine mounts and other critical assemblies.

Cummins QSB4.5 and QSB6.7 Engines

The QSB4.5 and QSB6.7 engines, known for their versatility in both industrial and agricultural applications, use the 3863364 in multiple configurations. This includes securing engine blocks, exhaust systems, and other vital components, ensuring that these engines operate smoothly and efficiently.

- QSB4.5 CM2250 EC

- QSB4.5 CM850 (CM2850)

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

Cummins QSB7 and QSC8.3 Engines

The QSB7 and QSC8.3 engines, which are designed for heavy-duty applications, also incorporate the 3863364. This screw is crucial for maintaining the structural integrity of these engines, ensuring that they can handle the rigors of demanding environments.

- QSB7 CM2880 B117

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

Cummins QSC9 and QSL9 Engines

The QSC9 and QSL9 engines, which are part of Cummins’ high-performance engine lineup, also utilize the 3863364. This screw is essential for securing various engine components, ensuring that these powerful engines operate reliably and efficiently.

- QSC9 CM2250 / QSL9 CM2250

- QSL9 CM554

- QSL9 CM850 (CM2850)

Role of 3863364 in Engine Systems

The 3863364 Hexagon Head Cap Screw is integral to the secure assembly and operation of various engine components. In alternator mounting applications, this screw ensures that the alternator is firmly attached to its bracket, allowing for stable operation and minimizing vibrations that could affect performance. The screw’s design facilitates easy installation and removal, which is essential during maintenance or repairs.

For general mounting purposes within the engine system, the 3863364 provides a reliable fastening solution. It is often used to secure covers, brackets, and other ancillary components, ensuring they remain in place under the dynamic conditions of engine operation. This stability is important for the longevity and efficiency of the engine.

Conclusion

The 3863364 Hexagon Head Cap Screw plays a significant role in maintaining the structural integrity and operational efficiency of engine systems by securely fastening critical components. Its durable construction, ease of installation, and resistance to loosening make it a valuable component in the maintenance and operation of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.