4394386

Hexagon Head Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Hexagon Head Cap Screw, part number 4394386, is a crucial component in commercial truck applications. This screw is instrumental in fastening various truck components, ensuring structural integrity and reliable performance. Understanding its function and significance is essential for maintaining and assembling commercial trucks effectively.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tool engagement. This design facilitates the application of torque, making it easier to install and remove the screw using common tools such as wrenches or sockets. The hexagonal shape prevents the tool from slipping off the screw head, providing a secure grip during installation and removal. This feature is particularly advantageous in high-torque applications, where precise and consistent force application is required 1.

Role of the 4394386 Hexagon Head Cap Screw in Truck Operation

This Cummins part is employed in various applications within commercial trucks. It is used to fasten components such as engine parts, chassis elements, and other critical assemblies. By securely holding these components in place, the screw contributes to the overall structural integrity of the truck. Additionally, it plays a role in maintaining the alignment and stability of truck components, which is essential for safe and efficient operation 2.

Key Features

The 4394386 Hexagon Head Cap Screw boasts several key features that enhance its performance and durability. It is typically made from high-strength materials such as alloy steel, which provides excellent tensile strength and resistance to wear. The screw features a threaded shaft that allows it to be driven into pre-drilled holes, creating a strong and secure connection. Additionally, it may be coated with anti-corrosion treatments to protect against rust and environmental damage, ensuring longevity in various operating conditions 3.

Benefits

This part offers several benefits that contribute to the reliability and longevity of truck components. Its corrosion-resistant properties help prevent rust and degradation, even in harsh environments. The high tensile strength of the screw ensures that it can withstand significant loads and stresses without failing. Furthermore, the ease of installation provided by its hexagonal head design allows for quick and efficient fastening, reducing downtime during maintenance and repair operations.

Troubleshooting and Maintenance

Common issues with Hexagon Head Cap Screws may include corrosion, stripping of the screw head, or loosening over time. To address these problems, regular inspection for signs of wear or corrosion is recommended. If corrosion is detected, the affected screws should be replaced to prevent further damage. In cases where the screw head has been stripped, specialized tools or replacement screws may be necessary. Proper torque settings during installation are crucial to ensure that the screws are tightened to the manufacturer’s specifications, preventing over-tightening or under-tightening that could lead to failure.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company is renowned for its expertise in diesel engines and related technologies, consistently delivering high-quality, innovative solutions that meet the demanding requirements of commercial trucking applications. Cummins’ commitment to quality and innovation ensures that its products, including the 4394386 Hexagon Head Cap Screw, are designed to provide reliable performance and durability in various operating conditions.

Cummins Hexagon Head Cap Screw 4394386 in Engine Applications

The Cummins Hexagon Head Cap Screw part number 4394386 is a critical component in various engine assemblies. This part is engineered to provide reliable fastening in demanding environments, ensuring the structural integrity and operational efficiency of the engines it supports.

B6.2 and CM2670 Engines

In the B6.2 and CM2670 engines, the 4394386 screw is utilized in several key areas. It is often found securing engine covers, housings, and other critical components that require robust fastening solutions. The precision and strength of this screw are essential for maintaining the alignment and stability of these parts, which directly impacts engine performance and longevity.

B156B Engine

The B156B engine also incorporates the 4394386 screw in its design. Here, it is used to fasten various engine components, ensuring that they remain securely in place under operational stresses. This screw’s design allows for easy installation and removal, which is crucial during maintenance and repair procedures.

Grouping of Engines

When considering the B6.2 and CM2670 engines together, it is evident that both utilize the 4394386 screw in similar applications. This commonality highlights the versatility and reliability of the screw in high-performance engine environments. The B156B engine, while distinct, also benefits from the same robust fastening capabilities provided by this part.

The use of the 4394386 screw across these engines underscores its importance in maintaining the structural and functional integrity of Cummins engine systems.

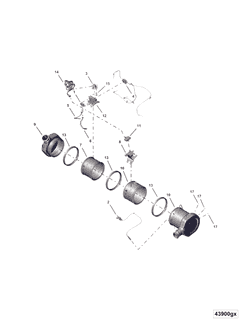

Role of Part 4394386 Hexagon Head Cap Screw in Aftertreatment Device

The part 4394386 Hexagon Head Cap Screw is integral to the assembly and functionality of the aftertreatment device in modern engine systems. This screw is utilized to secure various components within the aftertreatment system, ensuring that all parts remain firmly in place under operational conditions.

In the aftertreatment device, the 4394386 screw is commonly employed to fasten the Diesel Particulate Filter (DPF) to its housing. This secure attachment is essential for maintaining the structural integrity of the DPF, which is responsible for trapping and reducing particulate matter emitted by the engine.

Additionally, the screw is used in the mounting of the Selective Catalytic Reduction (SCR) system components. These components include the urea injection module and the catalyst itself. Proper fastening with the 4394386 screw ensures that the SCR system operates efficiently, converting harmful nitrogen oxides (NOx) into harmless nitrogen and water.

Furthermore, the screw plays a role in the attachment of sensors and monitoring devices within the aftertreatment system. These sensors are vital for providing real-time data on the performance of the aftertreatment components, allowing for timely maintenance and adjustments.

Overall, the 4394386 Hexagon Head Cap Screw is a key component in ensuring the reliable operation and durability of the aftertreatment device, contributing to the overall efficiency and environmental compliance of the engine system.

Conclusion

The Cummins Hexagon Head Cap Screw, part number 4394386, is a vital component in commercial truck applications, particularly in engine and aftertreatment systems. Its robust design, high tensile strength, and corrosion-resistant properties ensure reliable performance and durability. Regular maintenance and proper installation are crucial to maximizing the benefits of this part, contributing to the overall efficiency and safety of commercial trucks.

-

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.