This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4965326 Hexagon Head Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces this screw to meet the rigorous demands of truck operations. This screw is integral to the assembly and maintenance of various truck components, ensuring secure and reliable fastening in challenging environments.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tightening and loosening using standard tools such as wrenches or sockets. The design of the hexagonal head provides a robust grip, minimizing the risk of cam-out—a common issue with other screw head types. The screw’s threaded shaft engages with the internal threads of a nut or tapped hole, creating a strong and stable connection. This type of screw is commonly used in applications requiring high torque and secure fastening 1.

Purpose and Role in Truck Operation

The 4965326 Hexagon Head Cap Screw plays a significant role in commercial truck operations by securing various components and assemblies. It is often used in critical applications where vibration and dynamic loads are present, such as in the engine compartment, chassis, and other structural elements. By providing a reliable fastening solution, this screw helps maintain the integrity and safety of the truck’s components under operating conditions 2.

Key Features

The 4965326 Hexagon Head Cap Screw boasts several key features that enhance its performance and reliability. Its hexagonal head design allows for easy engagement with standard tools, facilitating quick and efficient installation and removal. The screw is typically made from high-strength materials, such as alloy steel, to withstand substantial loads and stresses. Additionally, it features precise threading specifications to ensure a secure fit and optimal torque transmission. The screw’s surface may be treated to improve corrosion resistance, extending its service life in harsh environments 3.

Benefits

The 4965326 Hexagon Head Cap Screw offers several benefits that make it a preferred choice for commercial truck applications. Its durable construction ensures long-lasting performance, even under demanding conditions. The screw’s resistance to loosening helps maintain secure fastenings over time, reducing the need for frequent re-tightening. Additionally, the ease of use with standard tools simplifies installation and maintenance procedures, enhancing overall efficiency.

Installation Guidelines

Proper installation of the 4965326 Hexagon Head Cap Screw is crucial for ensuring its effectiveness and longevity. Follow these guidelines for optimal results:

- Clean the Threads: Ensure that the mating threads are clean and free of debris to facilitate smooth engagement.

- Use the Correct Tool: Employ a wrench or socket that fits the hexagonal head precisely to avoid damage.

- Apply Torque Specifications: Adhere to the manufacturer’s torque specifications to achieve the correct clamping force without over-tightening.

- Check for Proper Seating: Ensure the screw is fully seated in the hole or nut to maximize thread engagement.

- Inspect the Connection: After installation, inspect the fastening to confirm it is secure and functions as intended.

Troubleshooting and Maintenance

Common issues with Hexagon Head Cap Screws include loosening due to vibration, corrosion, and wear. To troubleshoot and maintain these screws:

- Regular Inspection: Periodically check screws for signs of loosening or corrosion.

- Re-tighten as Needed: If screws show signs of loosening, re-tighten them to the specified torque.

- Replace Damaged Screws: Screws that are corroded or show signs of wear should be replaced to maintain secure fastenings.

- Use Corrosion-Resistant Coatings: Applying anti-seize compounds or coatings can help prevent corrosion and ease future removal.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products, including engines, powertrains, and aftermarket parts, designed to meet the needs of various industries. Cummins’ commitment to excellence and customer satisfaction has established it as a trusted name in the automotive and heavy-duty truck sectors.

Hexagon Head Cap Screw 4965326 in Cummins Engines

The Cummins Hexagon Head Cap Screw part number 4965326 is a critical component in several of Cummins’ engine models. This screw is integral to the assembly and maintenance of the QSB3.3 CM2250 EC, QSB4.5 CM2250 EC, and QSB6.7 CM2250 engines.

In the QSB3.3 CM2250 EC and QSB4.5 CM2250 EC engines, the 4965326 screw is used in various applications to ensure secure fastening of components. Its design allows for precise torque application, which is essential for maintaining the integrity of the engine’s structure and ensuring optimal performance.

For the QSB6.7 CM2250 engine, the 4965326 screw is similarly vital. Given the larger size and power of the QSB6.7 engine, the screw’s robust construction helps withstand the higher stresses and loads encountered in this engine. Its use in securing critical components ensures that the engine operates reliably under demanding conditions.

The consistent use of the 4965326 screw across these engine models highlights its importance in Cummins’ design philosophy, emphasizing reliability and durability in engine assembly.

Role of Part 4965326 Hexagon Head Cap Screw in Aftertreatment Systems

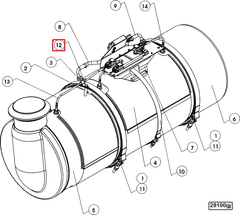

The part 4965326 Hexagon Head Cap Screw is instrumental in the assembly and maintenance of aftertreatment devices and systems. In the context of aftertreatment systems, this screw is commonly used to secure various components that are essential for reducing emissions and ensuring the engine operates within environmental regulations.

Application in Aftertreatment Devices

In aftertreatment devices, the 4965326 Hexagon Head Cap Screw is often employed to fasten components such as:

-

Catalytic Converters: These devices convert harmful exhaust gases into less harmful emissions. The screw ensures that the converter is securely mounted to the exhaust system, preventing vibrations and ensuring efficient operation.

-

Diesel Particulate Filters (DPF): The DPF captures soot and other particulate matter from the exhaust. The screw is used to attach the filter housing, maintaining structural integrity and sealing to prevent leaks.

-

Selective Catalytic Reduction (SCR) Systems: In SCR systems, the screw helps in securing the urea injection components, ensuring precise delivery and mixing of urea with exhaust gases for effective NOx reduction.

Integration within Aftertreatment Systems

Beyond individual devices, the 4965326 Hexagon Head Cap Screw plays a significant role in the broader aftertreatment system by:

-

Securing Mounting Brackets: It is used to fasten mounting brackets that hold aftertreatment components in place, ensuring they remain stable under the dynamic conditions of engine operation.

-

Connecting Pipes and Hoses: The screw is utilized in clamping connections for pipes and hoses within the aftertreatment system, maintaining airtight seals that are vital for system efficiency.

-

Attaching Sensors and Actuators: Many aftertreatment systems rely on sensors and actuators to monitor and control emissions. The screw is essential in attaching these components, ensuring they are correctly positioned and operational.

Conclusion

In summary, the 4965326 Hexagon Head Cap Screw is a fundamental fastening component in aftertreatment devices and systems, contributing to the secure assembly and reliable performance of these critical emissions control technologies. Its robust design, ease of use, and resistance to corrosion make it an essential part in the maintenance and operation of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.