S120

Hexagon Head Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The S120 Hexagon Head Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in the commercial truck industry. Cummins, a well-established name in the automotive sector, produces this screw to meet the demanding requirements of heavy-duty applications. This Cummins part is integral to the assembly and maintenance of commercial trucks, ensuring components are securely fastened and systems operate efficiently.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tightening and loosening using a wrench or socket. These screws are commonly used in mechanical assemblies to secure components together. The hexagonal shape of the head provides a firm grip, reducing the risk of cam-out and ensuring consistent torque application. In various applications, these screws play a role in maintaining the integrity and functionality of mechanical systems 1.

Purpose of the S120 Hexagon Head Cap Screw in Truck Operations

In the context of commercial trucks, the S120 Hexagon Head Cap Screw serves multiple functions. It is utilized in the assembly of engine components, where it helps secure critical parts in place, ensuring they remain stable under operational stress. Additionally, it is employed in the chassis and other structural elements of the truck, contributing to the overall durability and reliability of the vehicle. The screw’s design allows it to withstand the vibrations and loads encountered in heavy-duty truck operations 2.

Key Features of the S120 Hexagon Head Cap Screw

The S120 Hexagon Head Cap Screw is engineered with several design elements that enhance its functionality and durability. Its hexagonal head provides a robust interface for tools, facilitating easy installation and removal. The threaded shaft ensures a secure fit into mating components, while the material composition is chosen to offer resistance to corrosion and wear. These features collectively contribute to the screw’s performance in demanding environments 3.

Benefits of Using the S120 Hexagon Head Cap Screw

The S120 Hexagon Head Cap Screw offers several advantages for its users. Its design resists loosening over time, which is crucial in applications where vibrations are common. The ease of installation and removal allows for efficient maintenance procedures. Additionally, the screw is compatible with a variety of truck components, making it a versatile choice for different assembly needs. These benefits contribute to the reliability and longevity of commercial truck systems 4.

Installation Guidelines

Proper installation of the S120 Hexagon Head Cap Screw is vital for optimal performance. To install, ensure the mating surfaces are clean and free of debris. Use the appropriate wrench or socket to tighten the screw to the specified torque, avoiding over-tightening which can lead to damage. It is also important to periodically check the screw’s tightness during operation to prevent loosening.

Maintenance and Troubleshooting

Maintaining the S120 Hexagon Head Cap Screw involves regular inspection for signs of wear or corrosion. Common issues such as stripping can be addressed by replacing the screw or using a repair kit. Corrosion may be mitigated by applying a protective coating or using screws made from corrosion-resistant materials. Prompt attention to these issues helps ensure the continued reliability of the fastener.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality and innovation. The company’s product range includes engines, powertrains, and related components, serving a variety of industries including commercial trucking. Cummins’ dedication to excellence is reflected in its comprehensive approach to product development and customer support.

Cummins Engine Compatibility with S120 Hexagon Head Cap Screw

The S120 Hexagon Head Cap Screw, manufactured by Cummins, is a versatile component that fits into various engine models. This part is integral to the assembly and maintenance of these engines, ensuring secure fastening and reliable performance. Below is a detailed breakdown of the engines that are compatible with the S120 Hexagon Head Cap Screw.

Engine Series Compatibility

4B3.9 and 6B5.9 Series

The 4B3.9 and 6B5.9 engines are part of the older generation of Cummins engines, known for their robust design and durability. The S120 Hexagon Head Cap Screw is used in these engines to secure various components, ensuring that the engine operates smoothly and efficiently.

6C8.3 and G855 Series

The 6C8.3 and G855 engines represent a more modern approach to engine design, incorporating advanced technologies for improved performance and efficiency. The S120 Hexagon Head Cap Screw is utilized in these engines to maintain the integrity of critical assemblies, contributing to the overall reliability of the engine.

GTA38 G CMEICS G116C and GTA855 CM558 (CM2358) G101

These engines are part of the higher-performance range, often used in demanding applications. The S120 Hexagon Head Cap Screw is essential in these engines, providing the necessary strength and durability to withstand the rigors of heavy-duty operations.

ISM CM570, ISM CM570/870, and ISM11 CM876 SN

The ISM series engines are designed for commercial use, offering a balance of power and efficiency. The S120 Hexagon Head Cap Screw is used extensively in these engines to secure various parts, ensuring that the engine maintains its structural integrity under various operating conditions.

K19, K38, and K50 Series

The K-series engines are known for their versatility and reliability. The S120 Hexagon Head Cap Screw is a key component in these engines, providing the necessary fastening strength to keep the engine components securely in place.

KTA19GC, KTA19GC CM558, and KTA38GC CM558

These engines are designed for industrial applications, offering high performance and durability. The S120 Hexagon Head Cap Screw is used in these engines to ensure that all components are tightly secured, contributing to the engine’s overall reliability and longevity.

L10 Series

The L10 engines are part of the lighter-duty range, commonly used in various applications. The S120 Hexagon Head Cap Screw is used in these engines to secure various parts, ensuring that the engine operates smoothly and efficiently.

M11 Series

The M11 engines are known for their versatility and reliability. The S120 Hexagon Head Cap Screw is used in these engines to secure various components, ensuring that the engine maintains its structural integrity under various operating conditions.

N14 Series

The N14 engines are part of the heavy-duty range, offering high performance and durability. The S120 Hexagon Head Cap Screw is used in these engines to ensure that all components are tightly secured, contributing to the engine’s overall reliability and longevity.

Role of S120 Hexagon Head Cap Screw in Various Engine Components

The S120 Hexagon Head Cap Screw is a versatile fastener utilized across a multitude of engine components to ensure secure assembly and reliable operation. Its application spans several key areas within engine systems, contributing to the overall efficiency and durability of the machinery.

Actuator

In actuators, the S120 screw is employed to fasten the housing to the mounting bracket, ensuring that the actuator remains securely in place during operation. This is essential for maintaining the precise control of various engine functions.

Aftercooler Plumbing

For aftercooler plumbing, the S120 screw is used to secure the plumbing components to the engine frame. This ensures that the aftercooler system remains stable and does not shift during operation, which is vital for efficient cooling of compressed air.

Air Compressor

Within air compressors, the S120 screw plays a role in attaching the compressor housing to the engine block. This secure attachment is necessary to withstand the high pressures generated during compression cycles.

Air Starter Brackets

Air starter brackets utilize the S120 screw to mount the starter mechanism to the engine. This ensures that the starter remains firmly in place, allowing for reliable engine starts under various conditions.

Arrangement, Fuel Governor

In the arrangement of fuel governors, the S120 screw is used to secure the governor housing to the engine. This attachment is important for maintaining the governor’s position and ensuring accurate fuel delivery.

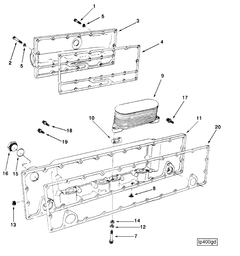

Camshaft Mounting Cover

The S120 screw is integral in fastening the camshaft mounting cover to the engine block. This secures the cover, protecting the camshaft and ensuring smooth operation of the valve train.

Cleaner, Air

For air cleaners, the S120 screw is used to attach the cleaner housing to the engine intake system. This ensures that the air cleaner remains in the correct position, facilitating efficient air filtration.

Connecting Rod and Piston

Although not directly attached to the connecting rod and piston, the S120 screw is used in the assembly of supporting structures and covers that house these components, ensuring they are held in place securely.

Conversion Kit

In conversion kits, the S120 screw is used to secure various components to the engine, facilitating the adaptation of the engine to different applications or fuel types.

Cooler, Torque Converter Mounting

For torque converter mounting, the S120 screw is employed to fasten the converter to the engine or transmission. This ensures that the converter remains stable during operation, contributing to smooth power transmission.

Drive, Fuel Pump

The S120 screw is used in the assembly of fuel pumps to secure the pump housing to the engine. This attachment is vital for maintaining the pump’s position and ensuring consistent fuel delivery.

Drive Arrangement, Fan

In fan drive arrangements, the S120 screw is utilized to attach the fan housing to the engine. This ensures that the fan remains in the correct position, aiding in effective engine cooling.

Filter Cooler

For filter coolers, the S120 screw is used to secure the cooler to the engine or frame. This stable attachment is necessary for maintaining the cooler’s efficiency in filtering and cooling fluids.

Flywheel

The S120 screw is employed in the attachment of the flywheel to the engine crankshaft. This secure connection is essential for smooth power transfer and engine balance.

Fuel and Mounting Filter

In fuel and mounting filters, the S120 screw is used to fasten the filter housing to the engine. This ensures that the filter remains in place, facilitating efficient fuel filtration.

Fuel Filter/Water Separator

For fuel filter/water separators, the S120 screw is utilized to secure the separator housing to the engine. This attachment is important for maintaining the separator’s position and ensuring effective water removal from the fuel.

Fuel Tubing

Although not directly attaching fuel tubing, the S120 screw is used in the assembly of fuel system components that support and route the tubing, ensuring a secure and leak-free system.

Mounting Alternator

The S120 screw is used to fasten the alternator to the engine. This secure attachment is necessary for maintaining the alternator’s position and ensuring reliable power generation.

Oil Pan Mounting Cover

For oil pan mounting covers, the S120 screw is employed to attach the cover to the engine block. This ensures that the cover remains in place, protecting the oil pan and its contents.

Oil Pan Mounting

In oil pan mounting, the S120 screw is used to secure the oil pan to the engine frame. This stable attachment is vital for maintaining the integrity of the oil pan and preventing oil leaks.

Radiator Connection

For radiator connections, the S120 screw is utilized to fasten the radiator to the engine or frame. This ensures that the radiator remains in the correct position, facilitating efficient cooling of the engine.

Rocker Lever Housing

In rocker lever housings, the S120 screw is used to secure the housing to the engine block. This attachment is important for maintaining the position of the rocker levers and ensuring smooth valve operation.

Sea Water Transfer

For sea water transfer systems, the S120 screw is employed to attach the transfer components to the engine or frame. This ensures that the system remains stable and efficient in transferring sea water for cooling purposes.

Service Kit & Pump

In service kits and pumps, the S120 screw is used to secure various components to the engine. This ensures that the components remain in place, facilitating efficient maintenance and operation.

Lub Oil

For lubrication oil systems, the S120 screw is utilized to fasten components such as filters and pumps to the engine. This secure attachment is necessary for maintaining the efficiency of the lubrication system.

Conclusion

The S120 Hexagon Head Cap Screw is a critical component in the assembly and maintenance of commercial trucks and various engine components. Its robust design, ease of installation, and resistance to wear and corrosion make it an ideal choice for heavy-duty applications. Proper installation and maintenance of this Cummins part ensure the reliability and longevity of the systems it supports.

-

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013

↩ -

Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings, Dominique Bonneau, Aurelian Fatu and Dominique Souchet, Wiley-ISTE, 2014

↩ -

Cars Encyclopedia, Clive Gifford, DK Publishing, 2014

↩ -

SAE International’s Dictionary for Automotive Engineers, John F Kershaw, SAE International, 2023

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.