This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins S144 Hexagon Head Cap Screw is a specialized fastener designed for use in heavy-duty truck components. Its robust construction and reliable performance in demanding environments make it integral to the assembly and maintenance of various truck systems, ensuring components remain securely fastened under significant stress and vibration 1.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is characterized by its hexagonal head, which allows for efficient tightening and loosening using standard tools such as wrenches or sockets. These screws are commonly used in the mechanical and automotive industries to join metal parts together, converting rotational force into linear force to create a secure connection 2.

Purpose and Role in Truck Operation

The S144 Hexagon Head Cap Screw is utilized in various truck systems, including the engine, transmission, and chassis. Its primary function is to provide a strong, durable connection between components subject to high levels of stress and vibration, ensuring the integrity and safety of the truck’s structure and systems 3.

Key Features

This Cummins part boasts several key features:

- Made from high-strength steel for durability and resistance to wear.

- Hexagonal head for easy tool engagement.

- Threaded shaft for a secure fit.

- May feature a unique coating or treatment to enhance corrosion resistance and longevity 4.

Benefits

Using the S144 Hexagon Head Cap Screw offers several advantages:

- High-strength material ensures durability under heavy loads and harsh conditions.

- Resistance to vibration helps maintain a secure connection over time.

- Compatibility with standard tools simplifies installation and maintenance processes 5.

Installation and Usage Guidelines

Proper installation of this part is vital for optimal performance and longevity. It should be installed using the correct torque specifications to ensure a secure yet not over-tightened connection. Recommended practices include:

- Cleaning the mating surfaces before installation.

- Using a torque wrench for accurate tightening.

- Periodically checking the screw’s tightness during maintenance intervals 6.

Troubleshooting and Maintenance

Common issues with Hexagon Head Cap Screws include loosening due to vibration, corrosion, and wear. Troubleshooting tips involve:

- Inspecting the screw and mating surfaces for signs of damage or corrosion.

- Ensuring proper torque during installation.

- Applying an appropriate anti-seize compound to prevent galling and facilitate future removal.

- Regular maintenance checks can help identify and address issues before they lead to component failure 7.

Safety Considerations

When handling and installing the S144 Hexagon Head Cap Screw, it is important to observe safety practices. This includes:

- Wearing personal protective equipment (PPE) such as gloves and safety glasses to protect against injury.

- Ensuring a stable work environment.

- Using the correct tools and techniques to prevent accidents and ensure a secure installation 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles 9.

Cummins Engine Compatibility with S144 Hexagon Head Cap Screw

The S144 Hexagon Head Cap Screw is a versatile component that fits into a variety of Cummins engines, providing essential fastening capabilities. Here’s how it integrates with specific engine models:

K-Series Engines

The K-Series engines, including the K19, K38, and K50, utilize the S144 Hexagon Head Cap Screw in several applications. This screw is particularly suited for securing components in these engines due to its robust design and compatibility with the engine’s structural requirements.

QSK-Series Engines

The QSK-Series engines, such as the QSK19 CM2350 K114, QSK19 CM2350 K144G, QSK19 CM500, QSK19 CM850 MCRS, and QSK19G, also benefit from the S144 Hexagon Head Cap Screw. This screw is integral in maintaining the integrity of the engine’s components, ensuring that parts remain securely fastened under operational stresses.

QST-Series Engines

The QST30 CM2350 T101 engine incorporates the S144 Hexagon Head Cap Screw in its assembly. This engine, known for its reliability and performance, relies on the screw to secure various parts, ensuring the engine operates smoothly and efficiently.

6C-Series Engines

The 6C8.3 engine is another model that utilizes the S144 Hexagon Head Cap Screw. This screw is essential in maintaining the structural integrity of the engine, providing a reliable fastening solution for various components.

V-Series Engines

The V28 engine also integrates the S144 Hexagon Head Cap Screw into its design. This screw is critical for securing components within the engine, ensuring that all parts remain firmly in place during operation.

The Cummins S144 Hexagon Head Cap Screw is a key component in the assembly and maintenance of these engines, providing the necessary fastening strength and durability required for optimal engine performance 10.

Role of S144 Hexagon Head Cap Screw in Engine Systems

The S144 Hexagon Head Cap Screw is integral to the assembly and functionality of various engine components. Its robust design and secure fastening capabilities make it suitable for a wide range of applications within engine systems.

Base Rail Mounting

In the base rail mounting system, the S144 screw ensures that the base rails are firmly attached to the engine frame. This secure attachment is essential for maintaining the structural integrity and alignment of the engine components.

Cooler and Torque Converter Mounting

For the cooler and torque converter mounting, the S144 screw plays a significant role in securing these components to the engine. Proper fastening is vital to ensure efficient heat exchange and smooth torque transmission, respectively.

Crossmember Mounting

When it comes to crossmember mounting, the S144 screw provides the necessary strength to hold the crossmembers in place. This is important for the overall stability and support of the engine structure.

Cylinder Block Assembly

In the cylinder block assembly, the S144 screw is used to fasten various parts together, ensuring that the cylinder block remains intact and functions correctly. This is fundamental for the engine’s combustion process.

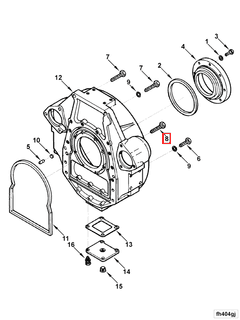

Flywheel Housing Support and Mounting

For the flywheel housing support and mounting, the S144 screw secures the flywheel housing to the engine, which is critical for the proper operation of the flywheel and the balance of the engine.

Front Engine Support

The front engine support relies on the S144 screw to maintain the engine’s position within the vehicle. This is important for the engine’s performance and the vehicle’s handling.

Hotstart Plumbing and Kim Hotstart

In the hotstart plumbing and Kim hotstart systems, the S144 screw ensures that all connections are tight and secure, which is essential for the reliable operation of the hotstart system.

Alternator and Injector Mounting

For alternator and injector mounting, the S144 screw provides a secure attachment point, ensuring that these components are properly positioned and function efficiently.

Radiator and Radiator Mounting

In the radiator and radiator mounting systems, the S144 screw helps to secure the radiator in place, which is vital for effective cooling of the engine.

Subbase and Power Train Support

The subbase and power train support systems utilize the S144 screw to ensure that all components are firmly attached, contributing to the overall stability and performance of the engine.

Rear Engine Support and Terminal Block

Finally, in the rear engine support and terminal block applications, the S144 screw provides the necessary fastening strength to secure these components, ensuring the engine operates smoothly and reliably 11.

Conclusion

The Cummins S144 Hexagon Head Cap Screw is a critical component in the assembly and maintenance of heavy-duty truck engines. Its robust design, high-strength material, and secure fastening capabilities ensure the integrity and reliability of various engine systems. Proper installation, maintenance, and adherence to safety practices are essential for optimal performance and longevity of this part.

-

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Atkins, R. D. (2009). An Introduction to Engine Testing and Development. SAE International.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Cummins Inc. (2011). QSF3.8 CM2350 F118, Service Manual (4388708).

↩ -

Cummins Inc. (2011). QSF3.8 CM2350 F118, Service Manual (4388708).

↩ -

Cummins Inc. (2011). QSF3.8 CM2350 F118, Service Manual (4388708).

↩ -

Cummins Inc. (2011). QSF3.8 CM2350 F118, Service Manual (4388708).

↩ -

Cummins Inc. (2011). QSF3.8 CM2350 F118, Service Manual (4388708).

↩ -

Cummins Inc. (2011). QSF3.8 CM2350 F118, Service Manual (4388708).

↩ -

Cummins Inc. (2011). QSF3.8 CM2350 F118, Service Manual (4388708).

↩ -

Cummins Inc. (2011). QSF3.8 CM2350 F118, Service Manual (4388708).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.