This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

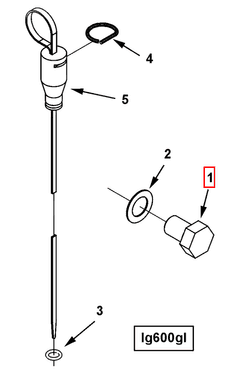

The S181C Hexagon Head Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces this screw to meet the demanding requirements of truck assembly and maintenance. The S181C is integral to ensuring the secure fastening of various components within commercial trucks, contributing to the overall reliability and performance of these vehicles 2.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tightening and loosening using a wrench or socket. These screws are commonly used in applications requiring a high degree of torque and secure fastening. Mechanically, the hexagonal head design provides a stable interface for tools, reducing the risk of cam-out and ensuring consistent torque application. The cap, or the covered end of the screw, protects the fastened surface from damage and debris, enhancing the screw’s functionality and durability 1.

Purpose of the S181C Hexagon Head Cap Screw in Truck Operations

The S181C Hexagon Head Cap Screw plays a specific role in the assembly and maintenance of commercial trucks. It is utilized in areas where secure and durable fastening is required, such as in the attachment of engine components, chassis parts, and various structural elements. Its design ensures that critical components remain firmly in place under the stress and vibration encountered during truck operations, contributing to the vehicle’s safety and performance 2.

Key Features of the S181C Hexagon Head Cap Screw

The S181C Hexagon Head Cap Screw is distinguished by several key features that enhance its functionality and durability. It is composed of high-strength materials, typically alloy steel, which provides resistance to wear and tear. The screw features a specific threading type that ensures a secure grip on the fastened material, reducing the likelihood of loosening over time. The hexagonal head design facilitates easy installation and removal, while the cap protects the screw and the fastened surface from environmental factors 2.

Benefits of Using the S181C Hexagon Head Cap Screw

Employing the S181C Hexagon Head Cap Screw in truck maintenance and assembly offers several advantages. Its resistance to corrosion ensures longevity in various environmental conditions, reducing the need for frequent replacements. The ease of installation, thanks to its hexagonal head, allows for efficient assembly processes. Additionally, its reliability under stress makes it a preferred choice for critical fastening applications in commercial trucks 2.

Installation and Usage Guidelines

Proper installation of the S181C Hexagon Head Cap Screw involves several steps to ensure secure and lasting fastening. Begin by selecting the appropriate size and type of screw for the application. Use a wrench or socket that fits the hexagonal head to tighten the screw to the specified torque, which can be found in the manufacturer’s guidelines. It is important to avoid over-tightening, which can damage the screw or the fastened material. Recommended tools include a torque wrench for precise torque application and a socket set for efficient tightening 2.

Troubleshooting and Maintenance

Common issues with Hexagon Head Cap Screws include loosening over time due to vibration or insufficient torque during installation. Regular inspection of screws for signs of wear, corrosion, or loosening is recommended to maintain the integrity of the fastened components. Maintenance tips include applying a thread locker to prevent loosening and ensuring that screws are tightened to the manufacturer’s specified torque. Replacement should be considered if screws show significant wear or damage 2.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s extensive product range includes engines, powertrains, and components designed to meet the demanding requirements of commercial vehicles. Cummins’ commitment to innovation and customer satisfaction makes it a preferred choice for truck components, including the S181C Hexagon Head Cap Screw 2.

Cummins Engine Compatibility with S181C Hexagon Head Cap Screw

The S181C Hexagon Head Cap Screw, manufactured by Cummins, is a versatile component that finds application across a range of their engines. This part is integral in securing various engine components, ensuring structural integrity and operational efficiency. Below is a detailed look at how this screw fits into different Cummins engines:

G855 CM558 and GTA855 CM558 (CM2358) Engines

The S181C screw is used in the assembly of the G855 CM558 and GTA855 CM558 (CM2358) engines. These engines are known for their robust design and high performance, and the S181C screw plays a critical role in maintaining the alignment and stability of the engine’s internal components.

G101, K19, K38, K50, KTA19GC, and KTA19GC CM558 Engines

In the G101, K19, K38, K50, KTA19GC, and KTA19GC CM558 engines, the S181C screw is utilized in various applications, including securing engine mounts, brackets, and other critical assemblies. Its use in these engines ensures that the engine components remain tightly fastened, which is crucial for the engine’s overall performance and longevity.

N14 MECHANICAL and NH/NT 855 Engines

The N14 MECHANICAL and NH/NT 855 engines also benefit from the S181C screw. In these engines, the screw is often used in the fastening of the cylinder head, engine block, and other structural components. Its high strength and durability make it an ideal choice for these applications.

QSK19 Series Engines

The S181C screw is compatible with several models in the QSK19 series, including QSK19 CM2350 K105, QSK19 CM2350 K114, QSK19 CM2350 K144G, QSK19 CM500, QSK19 CM850 MCRS, QSK19G, QSK38 CM2150 MCRS, and QSK38 CM850 MCRS engines. These engines are designed for a variety of applications, from marine to industrial use, and the S181C screw ensures that all components are securely fastened, contributing to the engine’s reliability and efficiency.

QSK50 Series Engines

In the QSK50 series, which includes QSK50 CM2150 K107, QSK50 CM2150 MCRS, QSK50 CM2350 K108, and QSK50 CM2350 K108 engines, the S181C screw is used to secure various engine components. Its precision and strength are essential for maintaining the structural integrity of these engines, which are known for their high power output and durability.

V28 and QSN14 CM876 N103 Engines

Finally, the S181C screw is also used in the V28 and QSN14 CM876 N103 engines. In these engines, the screw is crucial for securing components such as engine mounts and brackets, ensuring that the engine operates smoothly and efficiently.

Role of the S181C Hexagon Head Cap Screw in Engine Systems

The S181C Hexagon Head Cap Screw is integral to the assembly and secure functioning of various engine components. Its application spans across multiple systems, ensuring stability and reliability.

Oil System Components

In the oil system, the S181C screw is employed in the oil pan assembly to secure the oil pan to the engine block. This connection is vital for maintaining the integrity of the oil reservoir. Additionally, it is used in the front oil pan assembly to ensure a tight seal, preventing oil leaks.

The screw also plays a role in securing the oil level gauge and oil level sight glass to the oil pan. This is essential for accurate oil level readings, which are necessary for proper engine lubrication.

Cooling System Components

Within the engine cooling system, the S181C screw is utilized in the heat exchanger to fasten components that facilitate efficient heat transfer. It is also found in the expansion tank assembly, ensuring that the tank remains securely attached to the engine cooling system, which is important for maintaining coolant levels and pressure.

Gear and Conversion Kits

The S181C screw is crucial in the assembly of gear cover conversion kits. It secures the gear cover to the gearbox, ensuring that the internal components are well-protected and aligned. This is particularly important in high-stress environments where vibrations and movement could otherwise lead to misalignment.

Electrical and Sensor Components

In electrical systems, the screw is used to mount the electronic control module wiring harness. This ensures that the wiring remains secure and does not shift, which could lead to electrical faults. It also secures the EBM-gauge and other sensor components, ensuring accurate readings and reliable performance.

Miscellaneous Applications

The S181C screw is also employed in various miscellaneous applications such as securing the air intake manifold to the engine block, fastening the corrosion resistor in place, and attaching the water pump mounting guard. These applications highlight the screw’s versatility and importance in maintaining the structural integrity of the engine system.

Conclusion

In summary, the S181C Hexagon Head Cap Screw is a fundamental component in the secure assembly and operation of numerous engine systems, contributing to the overall reliability and performance of the engine 2.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.