3348182

Socket Head Cap Screw

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Socket Head Cap Screw, specifically Part #3348182 by Cummins, is a vital component in the realm of commercial trucks. Cummins, a renowned manufacturer in the industry, produces this screw to meet the demanding requirements of heavy-duty applications. This screw is integral to the fastening systems used in commercial trucks, ensuring components remain securely attached under various operational conditions.

Basic Concepts of Socket Head Cap Screws

A Socket Head Cap Screw is a type of fastener characterized by its cylindrical head with a hexagonal socket. This design allows for efficient tightening and loosening using a hex key, making it a preferred choice in applications where space is limited or where frequent adjustments are necessary. The screw’s threaded shaft engages with the internal threads of a component, creating a secure connection that can withstand significant stress 1.

Purpose of the 3348182 Socket Head Cap Screw in Truck Operations

The 3348182 Socket Head Cap Screw by Cummins serves a specific role in the operation and maintenance of commercial trucks. It is utilized in applications where a strong, reliable fastening solution is required. This screw helps in securing various components, ensuring they remain in place under the dynamic conditions experienced by commercial trucks. Its design and material properties contribute to the overall reliability and performance of the truck 2.

Key Features

The 3348182 Socket Head Cap Screw boasts several key features that make it suitable for heavy-duty applications. It is constructed from high-strength materials, ensuring durability under stress. The screw features a fine or coarse thread, depending on the application, allowing for a secure fit in various components. Its head design facilitates easy installation and removal using a hex key, enhancing efficiency in maintenance procedures 3.

Benefits

Utilizing the 3348182 Socket Head Cap Screw offers several advantages. Its high-strength material contributes to durability, reducing the likelihood of failure under load. The design of the screw head allows for easy installation and adjustment, saving time during maintenance. Additionally, the screw’s resistance to loosening ensures that components remain securely fastened, enhancing the safety and reliability of the truck 4.

Installation Procedures

Proper installation of the 3348182 Socket Head Cap Screw is crucial for optimal performance and safety. Begin by ensuring the mating threads are clean and free of debris. Use a hex key to start the screw by hand, aligning it with the internal threads. Once started, continue tightening until the desired torque is achieved, using a torque wrench to ensure accuracy. Avoid over-tightening, as this can damage the screw or the component being fastened.

Common Applications

The 3348182 Socket Head Cap Screw is commonly used in various applications within commercial trucks. It is found in engine components, where it secures parts that are subject to high stress and vibration. Additionally, it is used in chassis parts, contributing to the structural integrity of the truck. Other critical areas include brake systems and transmission components, where reliable fastening is paramount.

Troubleshooting and Maintenance

Identifying common issues with Socket Head Cap Screws, such as corrosion or stripping, is important for maintaining the performance and safety of commercial trucks. Regular inspection for signs of wear or damage can prevent failures. Maintenance practices, such as applying a thread locker to prevent loosening and ensuring proper torque settings during installation, can prolong the lifespan of these screws.

Safety Considerations

When working with Socket Head Cap Screws, adhering to safety practices is vital. Use the appropriate tools, such as hex keys and torque wrenches, to ensure accurate installation. Follow the recommended torque settings provided by the manufacturer to avoid over-tightening, which can lead to damage. Additionally, wear personal protective equipment (PPE) to safeguard against injuries during installation and maintenance procedures.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins serves commercial truck, bus, construction, agricultural, and power generation markets. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the rigorous demands of heavy-duty applications. Cummins’ dedication to quality and innovation ensures that its components, like the 3348182 Socket Head Cap Screw, contribute to the reliability and performance of commercial trucks.

Socket Head Cap Screw 3348182 Compatibility with Cummins Engines

The Socket Head Cap Screw part number 3348182, manufactured by Cummins, is a versatile component designed to fit various Cummins engine models. This part is integral in securing different parts within the engine assembly, ensuring structural integrity and operational efficiency.

ISC Series Engines

- ISC CM554

- ISC CM850

The Socket Head Cap Screw 3348182 is compatible with the ISC series engines, specifically the ISC CM554 and ISC CM850. This screw is used in various applications within these engines, including securing engine mounts, brackets, and other critical components.

ISL Series Engines

- ISL CM554

- ISL9 CM2150 SN

For the ISL series engines, the 3348182 screw fits both the ISL CM554 and the ISL9 CM2150 SN models. It is utilized in securing parts that require a robust fastening solution, ensuring that these components remain tightly secured under operational stresses.

ISX Series Engines

- ISX CM570

- ISX CM870

- ISX CM871

The ISX series engines, including the ISX CM570, ISX CM870, and ISX CM871, also utilize the Socket Head Cap Screw 3348182. This screw is essential for fastening various engine parts, contributing to the overall stability and performance of these engines.

QSC Series Engines

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

In the QSC series engines, the 3348182 screw is compatible with both the QSC8.3 CM554 and the QSC8.3 CM850 (CM2850). This screw is used in securing components that are critical to the engine’s operation, ensuring that these parts remain firmly attached.

QSL Series Engines

- QSL8.9 CM2150 L141

- QSL9 CM554

- QSL9 CM850 (CM2850)

The QSL series engines, including the QSL8.9 CM2150 L141, QSL9 CM554, and QSL9 CM850 (CM2850), also incorporate the Socket Head Cap Screw 3348182. This screw is used in securing various parts within these engines, ensuring that the components remain tightly fastened and operationally efficient.

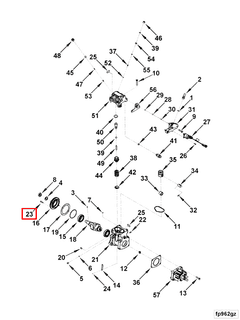

Role of Part 3348182 Socket Head Cap Screw in Engine Systems

The part 3348182 Socket Head Cap Screw is a versatile fastener that plays a significant role in the assembly and functionality of various engine components. Its design allows for secure and efficient fastening, which is essential for maintaining the integrity and performance of engine systems.

Actuator Kit

In the actuator kit, the Socket Head Cap Screw is used to secure the actuator to the engine block or other mounting surfaces. This ensures that the actuator remains firmly in place, allowing for precise control of engine functions such as variable valve timing or fuel injection.

Cam Housing and Cam Housing Module

Within the cam housing and cam housing module, the Socket Head Cap Screw is employed to fasten the housing to the engine block. This secure attachment is vital for maintaining the alignment and stability of the camshaft, which is essential for the proper operation of the valve train.

Fuel Control Housing and Fuel Control Module

For the fuel control housing and fuel control module, the Socket Head Cap Screw is utilized to attach the housing to the engine or fuel system components. This secure fastening ensures that the fuel control module operates within specified parameters, contributing to efficient fuel delivery and engine performance.

Fuel Injection Pump and Fuel Pump

In the fuel injection pump and fuel pump, the Socket Head Cap Screw is critical for securing various components within the pump assembly. This includes attaching the pump body to the engine or fuel system, ensuring that the pump operates smoothly and delivers fuel consistently.

Fuel Pump Assembly and Fuel Pump Body

The Socket Head Cap Screw is used in the fuel pump assembly and fuel pump body to fasten components such as the pump housing, impeller, and other internal parts. This secure attachment is necessary for the pump to function correctly, providing the necessary fuel pressure and flow for engine operation.

Fuel Pump Kit and Gear Fuel Pump

In the fuel pump kit and gear fuel pump, the Socket Head Cap Screw is employed to secure the pump to the engine or fuel system. This ensures that the pump remains stable and operates efficiently, delivering fuel to the engine under various conditions.

Gear Fuel Pump Kit

For the gear fuel pump kit, the Socket Head Cap Screw is used to fasten the pump components together and to the engine or fuel system. This secure attachment is essential for the reliable operation of the gear pump, ensuring consistent fuel delivery.

Pump, Fuel, and Pump, Fuel Injection

In both the fuel pump and fuel injection pump systems, the Socket Head Cap Screw is utilized to secure various components, ensuring that the pump operates within specified parameters. This includes attaching the pump body, impeller, and other internal parts, as well as securing the pump to the engine or fuel system.

The Socket Head Cap Screw’s role in these engine components underscores its importance in maintaining the structural integrity and operational efficiency of the engine system.

Conclusion

The 3348182 Socket Head Cap Screw by Cummins is a critical component in the maintenance and operation of commercial trucks. Its design, material properties, and compatibility with various Cummins engine models make it an essential fastener for securing critical engine components. Proper installation, maintenance, and adherence to safety practices ensure the longevity and reliability of this part, contributing to the overall performance and safety of commercial trucks.

-

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.