This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

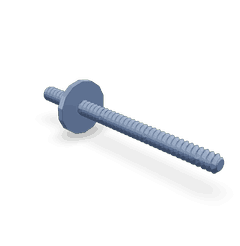

The 3045205 Studded Captive Washer Screw, manufactured by Cummins, is a critical component in the automotive and heavy-duty truck industries. This screw provides reliable fastening solutions, contributing to the efficient maintenance and operation of truck systems. Understanding its function and significance is essential for the upkeep and performance of truck systems.

Basic Concepts

A studded captive washer screw is a fastener that includes a stud, a captive washer, and a screw. The stud is a threaded rod that extends beyond the screw head, allowing for the attachment of additional components. The captive washer is integrated into the screw design, ensuring it remains in place during installation and operation. This type of screw secures various components within a truck’s mechanical system, providing stability and support 1.

Role and Function

The 3045205 Studded Captive Washer Screw secures components within a truck’s mechanical system, maintaining structural integrity. It is used in applications requiring a strong, reliable fastening solution. By securing parts in place, it ensures that the mechanical systems within a truck operate smoothly and efficiently 2.

Key Features

The 3045205 features a design that includes a stud and a captive washer, which are integral to its function. It is composed of materials that provide durability and resistance to wear, ensuring long-lasting performance. The screw’s design allows for easy installation and removal, while the captive washer ensures that the fastening solution remains secure over time 3.

Benefits

Using the 3045205 provides several advantages. Its design enhances durability, offering resistance to wear and tear that can occur over time. The captive washer ensures that the screw remains secure, providing a reliable fastening solution. Additionally, the screw’s material composition contributes to its performance, making it suitable for use in demanding applications 4.

Installation Process

Installing the 3045205 involves several steps. First, ensure that the area where the screw will be installed is clean and free of debris. Next, align the screw with the designated mounting point and begin threading it into place. Use a torque wrench to tighten the screw to the manufacturer’s specified torque setting, ensuring a secure fit without over-tightening. Finally, inspect the installation to confirm that the screw is properly seated and the captive washer is in place.

Maintenance and Troubleshooting

Maintaining the 3045205 involves regular inspection to check for signs of wear or damage. Look for any indications of corrosion, loosening, or damage to the captive washer. If any issues are detected, address them promptly to prevent further complications. Troubleshooting common issues may involve re-tightening the screw, replacing worn components, or addressing any underlying mechanical issues that may be affecting the screw’s performance.

Compatibility and Applications

The 3045205 is designed for use in heavy-duty truck applications, where reliable fastening solutions are required. It is compatible with various truck models and systems, providing a versatile fastening option for mechanics and technicians.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins has established a strong reputation within the automotive and heavy-duty truck industries. The company’s product range includes components and systems that contribute to the efficient operation and maintenance of vehicles, demonstrating its expertise and authority in the field.

Studded Captive Washer Screw (Part 3045205) in Cummins Engines

The Studded Captive Washer Screw, identified by the part number 3045205, is a critical component in the assembly and maintenance of several Cummins engines. This part is designed to provide a secure fastening mechanism, ensuring that various engine components remain tightly connected under operational stresses.

N14 CELECT and N14 MECHANICAL Engines

In the N14 CELECT and N14 MECHANICAL engines, the Studded Captive Washer Screw is utilized in several key areas. These engines, known for their robust design and reliability, often require precise and durable fastening solutions to maintain performance and longevity. The screw’s studded design ensures that it can withstand the high torque and vibrations typical of these engines, providing a reliable connection that is essential for the engine’s operation.

NH/NT 855 Engines

Similarly, in the NH/NT 855 engines, the Studded Captive Washer Screw is employed to secure various components. These engines are designed for heavy-duty applications, and the use of this screw helps to maintain the structural integrity of the engine under demanding conditions. The studded feature of the screw is particularly beneficial in this context, as it provides an additional layer of security, preventing loosening due to the rigors of continuous operation.

The integration of the Studded Captive Washer Screw in these engines highlights its importance in ensuring the overall reliability and performance of the engine. Its design and application across different engine models underscore its versatility and effectiveness in maintaining the integrity of engine components.

Role of Part 3045205 Studded Captive Washer Screw in Engine Systems

The 3045205 is instrumental in ensuring the secure and efficient assembly of various engine components. Its primary function is to provide a robust fastening solution that can withstand the dynamic forces and vibrations inherent in engine operation.

Aftercooler and Aftercooler Mounting

In the aftercooler system, the 3045205 is used to fasten the aftercooler to its mounting brackets. This secure attachment is essential for maintaining the structural integrity of the aftercooler, which is responsible for cooling the compressed air from the turbocharger before it enters the intake manifold. Proper fastening ensures that the aftercooler remains in place, allowing for optimal cooling efficiency and preventing potential damage from vibrations.

EBM: Location

At the EBM (exhaust brake module) location, the 3045205 plays a key role in securing the module to the engine block or exhaust system. This fastening is vital for the EBM to function correctly, as it relies on a stable and vibration-resistant mounting to modulate exhaust flow and provide engine braking. The screw’s design helps in distributing the load evenly, reducing the risk of loosening over time.

Turbocharger and Turbocharger Arrangement

In the turbocharger arrangement, the 3045205 is employed to secure various components such as the turbocharger housing to the engine block or the intake manifold. This secure attachment is necessary to maintain the turbocharger’s alignment and operational efficiency. The screw’s studded captive washer design ensures that the turbocharger remains firmly in place, even under high-stress conditions, thereby enhancing the overall performance and reliability of the turbocharger system.

Intake Manifold

The intake manifold often requires precise and secure fastening to ensure a leak-free seal and optimal air flow into the engine cylinders. The 3045205 is used to attach the intake manifold to the engine block, providing the necessary tension to maintain a seal while withstanding the thermal and mechanical stresses encountered during engine operation. This secure attachment is fundamental for the efficient operation of the engine, ensuring that air enters the cylinders without restriction or leakage.

Mounting Aftercooler

When mounting the aftercooler, the 3045205 is critical in securing the aftercooler to its designated location within the engine bay. This secure fastening is essential for the aftercooler’s function in cooling the compressed air, which directly impacts the engine’s performance and efficiency. The screw’s design ensures that the aftercooler remains stable and aligned, contributing to the overall effectiveness of the cooling process.

Conclusion

The 3045205 Studded Captive Washer Screw is a versatile and reliable fastening solution that plays a significant role in the secure and efficient assembly of various engine components, including the aftercooler, EBM, turbocharger, and intake manifold. Its robust design ensures that these components remain firmly in place, contributing to the engine’s overall performance and durability.

-

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ -

Zhan, Q., Eben, S., & Deng, L. K. (2018). Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning.

↩ -

Jazar, R. N. (2017). Vehicle Dynamics: Theory and Application. Springer.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.