4022820

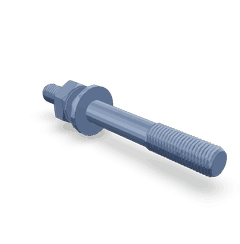

Studded Captive Washer Screw

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4022820 Studded Captive Washer Screw is a specialized fastener produced by Cummins, a well-established manufacturer in the commercial truck industry. This screw is designed for use in commercial trucks, where it plays a role in securing various components and ensuring the structural integrity of the vehicle.

Basic Concepts of Studded Captive Washer Screws

A studded captive washer screw consists of a threaded stud, a captive washer that is permanently attached to the stud, and a nut for fastening. The captive washer is designed to distribute the load more evenly across the surface it contacts, reducing the risk of damage to the fastened material. This type of screw is particularly useful in applications where vibration or movement could cause standard screws to loosen over time 1.

Purpose and Role in Truck Operation

In the context of commercial truck operations, the Studded Captive Washer Screw serves to secure critical components, ensuring they remain firmly in place under various driving conditions. Its design helps maintain the structural integrity of the truck by providing a reliable fastening solution that resists loosening due to vibration or other dynamic forces encountered during operation.

Key Features

The 4022820 features a robust design that includes a high-strength steel stud and a captive washer made from a durable material. This Cummins part is engineered to withstand the rigors of commercial truck environments, offering enhanced performance through its resistance to wear and corrosion. Additionally, the captive washer design ensures that the washer remains in place, simplifying the installation process and reducing the likelihood of loss during maintenance.

Benefits

The benefits of using the Studded Captive Washer Screw include improved fastening security, enhanced resistance to vibration, and increased longevity in harsh operating conditions. Its design contributes to more reliable fastening solutions, reducing the need for frequent re-tightening or replacement. This results in lower maintenance costs and improved safety for commercial truck operations 2.

Installation Process

To install the 4022820, begin by ensuring the surface is clean and free of debris. Position the screw so that the stud aligns with the intended fastening point. Use a compatible wrench to tighten the nut until the desired torque is achieved, ensuring the screw is securely fastened without over-tightening, which could damage the screw or the fastened material.

Troubleshooting Common Issues

Common issues with studded captive washer screws may include loosening over time or corrosion in exposed areas. To address loosening, ensure the screw is properly torqued during installation and consider the use of lock washers or thread locker for additional security. For corrosion, regular inspection and cleaning can help prevent buildup, and applying a corrosion-resistant coating may further protect the screw.

Maintenance Tips

Regular maintenance of studded captive washer screws involves periodic inspection for signs of wear, corrosion, or loosening. Cleaning the screws and surrounding areas can help prevent buildup that may lead to corrosion. Additionally, ensuring that all screws are properly torqued during routine maintenance checks can help maintain the integrity of the fastening system.

Cummins: Manufacturer Overview

Cummins is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality products. With a history of innovation and excellence, Cummins has established a strong reputation for producing reliable and durable components. Their product range includes engines, powertrains, and various aftermarket parts, all designed to meet the demanding requirements of commercial truck operations.

Studded Captive Washer Screw (Part 4022820) in Cummins Engines

The Studded Captive Washer Screw, identified by the part number 4022820, is a critical component in various Cummins engine models. This part is integral to the assembly and maintenance of these engines, ensuring secure fastening and stability. Here’s how it fits into different Cummins engine configurations:

ISM Series Engines

-

ISM CM570 and ISM CM570/870: The Studded Captive Washer Screw is used in these engines to secure various components, ensuring that parts remain tightly fastened under operational conditions. This is particularly important in maintaining the integrity of the engine’s structure and performance.

-

ISM CM876 and ISM11 CM876 SN: In these models, the screw is employed in several critical areas, including the attachment of engine mounts and other structural components. Its design ensures that the washer remains captive, preventing loss during operation.

ISX Series Engines

-

ISX12 G CM2180 EJ: The Studded Captive Washer Screw is utilized in this engine to secure various parts, including those in the exhaust system and other high-stress areas. Its studded design provides additional grip and stability, crucial for the engine’s longevity and performance.

-

ISX12/ISX11.9 CM2250: This engine model also benefits from the use of the Studded Captive Washer Screw, particularly in areas where high torque and vibration are common. The screw’s design ensures that the washer stays in place, providing reliable fastening.

QSX Series Engines

-

QSX11.9 CM2250 ECF: In this engine, the screw is used in several key locations, including the attachment of components that are subject to significant stress and vibration. Its studded feature helps maintain the washer’s position, ensuring the engine’s components remain securely fastened.

-

QSX15 CM2350 X105: This engine model also incorporates the Studded Captive Washer Screw in various critical areas. The screw’s design is particularly beneficial in high-stress environments, ensuring that the washer remains captive and the components are securely fastened.

Role of Part 4022820 Studded Captive Washer Screw in Engine Systems

The part 4022820 studded captive washer screw is integral to the secure and efficient operation of various engine components. In the arrangement of the turbocharger, this screw ensures that the compressor and turbine are held firmly in place, allowing for optimal air compression and exhaust gas flow.

Within the air module, the screw plays a key role in maintaining the integrity of the air intake manifold. By securing the mounting points, it ensures that the manifold remains stable under varying engine loads and conditions. This stability is essential for consistent air delivery to the engine cylinders.

In the engine control system, the studded captive washer screw is used in the intake connection mounting. This ensures that the connection between the air intake manifold and the engine is secure, preventing any leaks that could affect engine performance.

Furthermore, in the intake manifold plumbing, the screw helps in maintaining the precise alignment and sealing of various components. This is vital for the efficient flow of air into the engine, directly influencing combustion efficiency and overall engine performance.

Overall, the 4022820 studded captive washer screw is a fundamental component in ensuring the secure and efficient integration of various engine systems, contributing to the reliable operation of the engine as a whole.

Conclusion

The 4022820 Studded Captive Washer Screw is a critical component in the commercial truck industry, offering reliable fastening solutions that enhance the structural integrity and performance of commercial trucks. Its robust design, resistance to wear and corrosion, and ease of installation make it an invaluable part in the maintenance and operation of Cummins engines. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, ensuring long-term reliability and efficiency in commercial truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.