This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

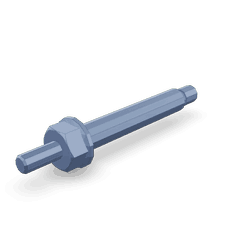

The 3920345 Studded Flange Cap Screw is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This screw is designed for use in heavy-duty truck applications, where it plays a role in ensuring the reliability and functionality of various truck components.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that includes a threaded stud and a cap screw. It is commonly used in mechanical systems to secure flanges, which are flat discs or plates that connect pipes, valves, and other equipment. Within an assembly, the studded flange cap screw provides a secure connection that can withstand significant stress and vibration 1.

Purpose and Role in Truck Operation

In heavy-duty trucks, the 3920345 Studded Flange Cap Screw serves a specific purpose by securing flanges in critical areas such as the engine, transmission, and exhaust systems. Its role is to maintain the integrity of these connections, ensuring that components remain firmly in place under the demanding conditions typical of heavy-duty operations. This contributes to the overall functionality and reliability of the truck 2.

Key Features

The 3920345 Studded Flange Cap Screw is characterized by several key features that enhance its performance. It is made from high-quality materials, typically a durable alloy steel, which provides strength and longevity. The design includes a studded flange that allows for a secure fit, and the cap screw is engineered to distribute stress evenly across the connection. Additionally, the screw may feature unique characteristics such as a corrosion-resistant coating to improve its durability in various environments 3.

Benefits

Using the 3920345 Studded Flange Cap Screw offers several benefits. Its durable material composition and robust design contribute to improved longevity and reliability. The screw’s ability to provide a strong and secure connection enhances the fastening capabilities in heavy-duty applications. Furthermore, its resistance to wear and corrosion ensures that it maintains performance over time, even in harsh operating conditions.

Installation Process

Proper installation of the 3920345 Studded Flange Cap Screw is crucial for ensuring a secure fit. The process involves aligning the screw with the flange, using appropriate tools to tighten it to the manufacturer’s specified torque, and verifying that the connection is secure. Best practices include checking for any signs of damage or wear before installation and ensuring that all mating surfaces are clean and free of debris.

Troubleshooting and Maintenance

Common issues with the 3920345 Studded Flange Cap Screw may include loosening over time or corrosion. Troubleshooting steps involve inspecting the screw for signs of wear, ensuring that it is tightened to the correct torque, and addressing any environmental factors that may contribute to corrosion. Regular maintenance, such as periodic inspection and re-torquing, can help prolong the lifespan of the screw and ensure optimal performance.

Compatibility and Applications

The 3920345 Studded Flange Cap Screw is typically used in various applications within heavy-duty trucks, including but not limited to, engine, transmission, and exhaust system connections. It is compatible with a range of systems and components, making it a versatile choice for maintaining secure connections in demanding environments.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. The company’s product range includes a variety of components and systems designed to meet the needs of demanding applications, ensuring that vehicles operate efficiently and reliably.

Studded Flange Cap Screw (Part 3920345) in Cummins Engines

The Studded Flange Cap Screw, part number 3920345, is a component in the assembly and maintenance of various Cummins engines. This part is designed to secure flanges, ensuring a tight and reliable seal, which is essential for the proper functioning of the engine.

Application in Cummins Engines

6C8.3

In the 6C8.3 engine, the Studded Flange Cap Screw is used in several critical areas where flanges need to be fastened securely. This includes connections for exhaust systems, fuel lines, and other fluid pathways. The screw’s design ensures that these connections remain leak-proof under high-pressure conditions.

C GAS PLUS CM556

For the C GAS PLUS CM556 engine, the Studded Flange Cap Screw is integral to maintaining the integrity of the engine’s gas handling components. It is used in the assembly of various flanges that connect to the intake and exhaust systems, ensuring that the engine operates efficiently and safely.

ISL G CM2180

In the ISL G CM2180 engine, this screw is employed in numerous applications, including securing flanges in the cooling system, exhaust system, and other critical fluid pathways. Its robust design helps maintain the structural integrity of these connections, which is vital for the engine’s performance and longevity.

Grouping of Engines

The Studded Flange Cap Screw is a versatile component that finds application across different Cummins engine models. The 6C8.3 and C GAS PLUS CM556 engines share similar design philosophies, making the screw a common element in their assemblies. The ISL G CM2180 engine, while more advanced, also relies on this screw for its flange connections, ensuring that the engine’s various systems remain securely fastened.

Role of Part 3920345 Studded Flange Cap Screw in Engine Systems

The 3920345 studded flange cap screw is a component in various engine systems, providing secure and reliable fastening for multiple parts. Its design and functionality are integral to the proper operation and maintenance of these systems.

Valve Cover Assembly

In the valve cover assembly, the 3920345 studded flange cap screw ensures a tight and leak-proof seal. This is vital for maintaining the integrity of the engine’s lubrication system. The screw secures the valve cover to the cylinder head, preventing oil leaks and ensuring that the valve train components are properly lubricated.

Valve and Mounting Arrangements

When it comes to valve and mounting arrangements, the 3920345 screw plays a role in securing valve components to their respective mounts. This ensures that the valves operate smoothly and efficiently, contributing to the overall performance and reliability of the engine. The screw’s studded flange design provides additional stability and resistance to vibration, which is crucial for high-performance engines.

Plumbing and Air Fuel Control Systems

In plumbing and air fuel control systems, the 3920345 screw is used to fasten various components, such as sensors, regulators, and control units. Its robust design ensures that these components remain securely in place, even under varying engine conditions. This is particularly important in systems where precise control and measurement are required, such as in fuel injection and emissions control systems.

General Engine Components

Across various engine components, the 3920345 studded flange cap screw is employed to fasten covers, plates, and other structural elements. Its ability to provide a strong and durable connection makes it a preferred choice for applications where reliability and longevity are paramount. Whether securing an engine cover or a critical sensor, this screw ensures that all components remain firmly in place, contributing to the engine’s overall stability and performance.

Conclusion

The 3920345 Studded Flange Cap Screw is a critical component in heavy-duty truck applications, ensuring the reliability and functionality of various truck components. Its robust design, durable material composition, and secure fastening capabilities make it an essential part in the assembly and maintenance of Cummins engines. Proper installation, regular maintenance, and understanding its role in engine systems are key to maximizing the performance and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.