This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

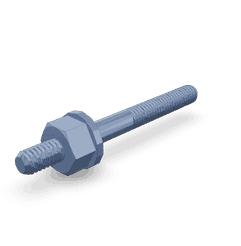

The 3930320 Studded Flange Cap Screw is a specialized fastener produced by Cummins, a well-established manufacturer known for its high-quality automotive components. This particular screw is designed for use in commercial trucks, where it plays a significant role in ensuring the secure assembly of various components. Its robust construction and precise engineering make it suitable for the demanding conditions encountered in heavy-duty applications 1.

Basic Concepts of Studded Flange Cap Screws

A Studded Flange Cap Screw is a type of fastener that incorporates a threaded stud and a flanged head. This design allows it to secure components effectively by distributing clamping force over a larger area compared to traditional bolts. The flange provides additional stability and resistance to rotation, making it ideal for applications where vibration and movement are common 2. In mechanical assemblies, these screws are often used to join parts that require a strong, permanent connection.

Purpose of the 3930320 Studded Flange Cap Screw

In the context of commercial trucks, the 3930320 Studded Flange Cap Screw serves to secure critical components, ensuring they remain firmly in place under various operating conditions. This screw is particularly important in applications where components are subjected to significant stress, vibration, or thermal expansion. By providing a reliable fastening solution, it contributes to the overall durability and performance of the truck 3.

Key Features

The 3930320 Studded Flange Cap Screw boasts several key features that enhance its functionality and reliability. It is constructed from high-strength materials, ensuring it can withstand the rigors of heavy-duty use. The screw’s design includes a flanged head that offers increased resistance to loosening, and the threaded stud allows for easy installation and removal. Additionally, the screw may feature unique characteristics such as corrosion-resistant coatings or specialized threading to further improve its performance in challenging environments 4.

Benefits

Using the 3930320 Studded Flange Cap Screw offers several advantages. Its durable construction ensures long-lasting performance, reducing the need for frequent replacements. The screw’s design enhances reliability by providing a secure connection that resists loosening over time. Furthermore, its ability to distribute clamping force effectively contributes to the overall stability and integrity of the assembled components, leading to improved performance in heavy-duty applications 5.

Installation Process

Proper installation of the 3930320 Studded Flange Cap Screw is crucial to ensure optimal performance and longevity. Begin by cleaning the mating surfaces to remove any debris or contaminants. Next, align the screw with the designated hole and insert the threaded stud. Use a torque wrench to tighten the screw to the manufacturer’s specified torque settings, ensuring even clamping force is applied. Finally, inspect the installation to confirm that the screw is securely fastened and that there are no signs of damage or misalignment 6.

Troubleshooting Common Issues

Common issues with Studded Flange Cap Screws may include loosening, corrosion, or damage to the threading. To address these problems, first, ensure that the screw is properly torqued during installation. If loosening occurs, re-tighten the screw to the specified torque settings. In cases of corrosion, clean the affected area and apply a corrosion-resistant coating if necessary. If the threading is damaged, replace the screw to maintain the integrity of the connection 7.

Maintenance Tips

Regular maintenance practices can help prolong the life of the 3930320 Studded Flange Cap Screw and ensure continued reliable operation. Inspect the screw periodically for signs of wear, corrosion, or damage. Clean the mating surfaces and the screw itself to remove any buildup of dirt or debris. Re-torque the screw as needed to maintain the proper clamping force. Additionally, apply a corrosion-resistant coating if the environment is particularly harsh to protect the screw from degradation 8.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer with a long-standing reputation in the automotive industry. Founded in 1919, the company has built a legacy of producing high-quality components for a variety of applications, including commercial trucks, agricultural equipment, and industrial machinery. Cummins is committed to innovation, quality, and customer satisfaction, consistently delivering products that meet the demanding requirements of heavy-duty use. Their expertise and dedication to excellence make them a trusted name in the industry 9.

Compatibility of 3930320 Studded Flange Cap Screw with Cummins Engines

The 3930320 Studded Flange Cap Screw, manufactured by Cummins, is a critical component in various engine configurations. This part is designed to secure flanges and other components, ensuring a tight and reliable seal. Here is a detailed look at its compatibility with different Cummins engines:

- 4B3.9

- 6B5.9

- 6C8.3

- B6.7 CM2670 B153B

- ISB/ISD4.5 CM2150 B119

- ISB5.9 CM2880 B127

- ISBE CM2150

- ISBE4 CM850

- ISZ13 CM2150 Z105

- L9.3 L105

- QSB5.9 CM2880 B139

- QSZ13 CM2150 Z101

- V903

This part is engineered to fit seamlessly into these engines, providing the necessary strength and durability to withstand the operational stresses of the engine environment. Its studded design ensures a secure fit, which is crucial for maintaining the integrity of flange connections and preventing leaks 10.

Role of 3930320 Studded Flange Cap Screw in Engine Systems

The 3930320 studded flange cap screw is instrumental in securing and maintaining the integrity of various components within engine systems. In the context of the Air Heater Starting Aid, this screw ensures that the air heater components are firmly attached, allowing for efficient preheating of the intake air, which is essential for smooth engine start-ups in cold conditions.

Within the Injection Starting Aid, the 3930320 screw plays a significant role in securing fuel injection components. This ensures precise fuel delivery and consistent engine performance during start-up, particularly in environments where low temperatures could otherwise impede efficient fuel injection.

For the Air Intake Heater, the 3930320 screw is used to fasten the heater elements securely in place. This is vital for the uniform distribution of heat across the intake air, enhancing combustion efficiency and reducing emissions.

In the Heater Kit, this screw is employed to assemble various heater components, ensuring they function cohesively to provide the necessary warmth to critical engine parts, thus facilitating easier starts and better overall performance.

Lastly, in the Engine Control Module (ECM), the 3930320 screw is utilized to secure the module housing. This ensures that the ECM remains stable and protected, allowing it to accurately monitor and control engine operations, including the coordination of the aforementioned starting aids and heaters 11.

Conclusion

The 3930320 Studded Flange Cap Screw is a vital component in the assembly and maintenance of commercial truck engines. Its robust design, compatibility with a wide range of Cummins engines, and critical role in securing various engine components make it an indispensable part in ensuring the durability and performance of heavy-duty applications. Proper installation, regular maintenance, and understanding its role in engine systems are essential for maximizing the benefits of this Cummins part.

-

Peters, G., & Peters, B. J. (2002). Automobile Vehicle Safety. CRC Press.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Reif, K. (Ed.). (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). QST30 CM2350 T103C Service Manual (6309062).

↩ -

Peters, G., & Peters, B. J. (2002). Automobile Vehicle Safety. CRC Press.

↩ -

Cummins Inc. (n.d.). QST30 CM2350 T103C Service Manual (6309062).

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Reif, K. (Ed.). (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Company History. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). QST30 CM2350 T103C Service Manual (6309062).

↩ -

Cummins Inc. (n.d.). QST30 CM2350 T103C Service Manual (6309062).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.