3935105

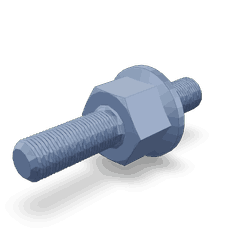

Studded Flange Cap Screw

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Studded Flange Cap Screw, identified by Part #3935105, is a component manufactured by Cummins, a renowned name in the automotive and heavy-duty truck industry. This screw is integral to the mechanical systems of heavy-duty trucks, ensuring the secure attachment of various components. Cummins, with its extensive history and reputation for quality, provides this part as part of its comprehensive range of products designed to enhance the performance and reliability of heavy-duty vehicles 2.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener characterized by its threaded shank and a head with a flange. The flange provides a larger surface area for distribution of clamping force, reducing the risk of damage to the fastened material. In the context of a truck’s mechanical system, this screw plays a role by securely attaching components, ensuring they remain in place under various operational stresses 3.

Purpose and Role in Truck Operation

The 3935105 Studded Flange Cap Screw is utilized in various truck systems where secure fastening is required. It is commonly found in engine components, transmission systems, and other critical areas where vibrations and stresses are prevalent. By providing a robust connection, it contributes to the overall stability and efficiency of the truck’s operation 4.

Key Features

The 3935105 Studded Flange Cap Screw is crafted from high-quality materials, ensuring durability and resistance to corrosion. Its design includes a studded flange that enhances the distribution of clamping force, minimizing the risk of damage to the fastened components. Additionally, the screw is engineered to withstand high torque applications, making it suitable for the demanding environments of heavy-duty trucks 1.

Benefits

Utilizing the 3935105 Studded Flange Cap Screw offers several advantages. Its robust construction ensures longevity, reducing the need for frequent replacements. The design enhances reliability by providing a secure attachment, even in high-stress environments. Furthermore, its efficiency in maintaining component integrity contributes to the overall performance and safety of the truck 2.

Installation Process

Proper installation of the 3935105 Studded Flange Cap Screw involves several steps. Begin by ensuring the mating surfaces are clean and free from debris. Apply the appropriate torque specifications to secure the screw in place, taking care not to over-tighten, which could damage the components or the screw itself. It is also important to verify the alignment of the screw with the flange to ensure optimal performance 3.

Troubleshooting and Maintenance

Common issues with the 3935105 Studded Flange Cap Screw may include loosening over time due to vibrations or corrosion. Regular inspection and maintenance are recommended to address these concerns. If loosening is detected, re-tightening to the specified torque is advised. Additionally, applying a thread locker can help prevent future loosening. For corrosion, cleaning the affected area and applying a protective coating may be necessary 4.

Safety Considerations

When working with the 3935105 Studded Flange Cap Screw, it is important to observe safety guidelines. Ensure proper handling to avoid injury from sharp edges or high torque applications. Store the screws in a dry, corrosion-resistant environment to maintain their integrity. Always use the correct tools and follow torque specifications to prevent damage to the screw or the components it secures 1.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industry. Their product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of vehicles across the globe 2.

Compatibility with Cummins Engines

The Studded Flange Cap Screw part number 3935105, manufactured by Cummins, is a critical component used in various engine applications. This part is designed to secure flanges and other components, ensuring a tight and reliable seal. Below is a detailed overview of its compatibility with the listed Cummins engines:

ISB Series Engines

- ISB (Chrysler)

- ISB CM850

- ISB6.7 G CM2180 B118

The Studded Flange Cap Screw 3935105 is compatible with the ISB series engines, including the ISB (Chrysler), ISB CM850, and ISB6.7 G CM2180 B118. These engines are known for their robust performance and reliability, often used in heavy-duty applications.

ISC Series Engines

- ISC CM2150

- ISC CM850

- ISC8.3 CM2250

This part fits seamlessly with the ISC series engines, such as the ISC CM2150, ISC CM850, and ISC8.3 CM2250. These engines are designed for medium-duty applications, providing a balance between power and efficiency.

ISG Series Engines

- ISG11 CM2880 G108

- ISG12 CM2880 G107

- ISG12 G CMOH6.0 G111

The Studded Flange Cap Screw 3935105 is also suitable for the ISG series engines, including the ISG11 CM2880 G108, ISG12 CM2880 G107, and ISG12 G CMOH6.0 G111. These engines are typically used in applications requiring high power output and durability.

ISL Series Engines

- ISL CM2150

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

- ISL9.5 CM2880 L138

This part is compatible with the ISL series engines, such as the ISL CM2150, ISL G CM2180, ISL9 CM2150 SN, ISL9 CM2250, and ISL9.5 CM2880 L138. These engines are widely used in various industries for their versatility and performance.

ISX Series Engines

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

The Studded Flange Cap Screw 3935105 is also suitable for the ISX series engines, including the ISX15 CM2250, ISX15 CM2250 SN, and ISX15 CM2350 X101. These engines are known for their high power output and are often used in heavy-duty applications.

L Series Engines

- L8.9

- L8.9 CM2670 L134C

- L8.9 L121

- L8.9G CMOH2.0 L125B

- L9 CM2670 L128B

The part fits the L series engines, such as the L8.9, L8.9 CM2670 L134C, L8.9 L121, L8.9G CMOH2.0 L125B, and L9 CM2670 L128B. These engines are designed for heavy-duty applications, providing exceptional power and reliability.

By ensuring the proper fitment of the Studded Flange Cap Screw 3935105, technicians and engineers can maintain the integrity and performance of these Cummins engines 2.

Role of Part 3935105 Studded Flange Cap Screw in Engine Systems

The 3935105 studded flange cap screw is an integral component in various engine systems, ensuring secure and reliable connections across multiple assemblies. Its application spans several key areas, enhancing the functionality and safety of the engine.

Accessories and Electric Starting

In the context of accessories and electric starting systems, the 3935105 studded flange cap screw is employed to fasten components securely. This includes mounting electric starters and ensuring that accessories like alternators and generators are firmly attached to the engine block. The screw’s design allows for a robust connection, minimizing the risk of vibration-induced loosening 3.

Compressor Coolant and Oil Systems

For compressor coolant and oil systems, the 3935105 studded flange cap screw plays a significant role in maintaining the integrity of plumbing and connections. It is used to secure fittings and gauges in oil fill and compressor coolant arrangements, ensuring that these systems operate under precise pressure and temperature conditions. The screw’s studded flange provides additional surface area for a tighter seal, preventing leaks that could compromise engine performance 4.

Hand Hole and Gauge Covers

In the assembly of hand holes and gauge covers, the 3935105 studded flange cap screw ensures that these components are securely fastened to the engine. This is particularly important for hand holes, which provide access for maintenance and inspection, and gauge covers, which protect sensitive instruments from damage. The screw’s design facilitates easy installation and removal, aiding in routine maintenance procedures 1.

Oil Level and Mounting Applications

When it comes to oil level indicators and mounting brackets, the 3935105 studded flange cap screw is utilized to secure these elements to the engine. Accurate oil level readings are essential for engine health, and the screw ensures that the gauge remains in place and functions correctly. Additionally, for lifting brackets and other mounting applications, the screw provides a strong and reliable connection, supporting the weight and stress during engine handling and transportation 2.

Auxiliary Support and Accessory Switches

In auxiliary support systems and accessory switches, the 3935105 studded flange cap screw is crucial for maintaining the structural integrity of these components. It is used to attach support brackets and secure switches, ensuring that auxiliary systems like fuel pumps and magnetic components operate efficiently. The screw’s design enhances the durability of these connections, contributing to the overall reliability of the engine system 3.

Plumbing and Pump Assemblies

Finally, in plumbing and pump assemblies, the 3935105 studded flange cap screw is instrumental in securing fittings and connections. It ensures that fluid pathways remain intact, preventing leaks and maintaining the efficiency of fluid transfer within the engine. The screw’s application in these systems underscores its versatility and importance in engine maintenance and operation 4.

Conclusion

The 3935105 Studded Flange Cap Screw is a critical component in the maintenance and operation of heavy-duty trucks and engines. Its robust design, compatibility with various Cummins engines, and versatile applications across different engine systems make it an essential part for ensuring the reliability and performance of these vehicles. Proper installation, regular maintenance, and adherence to safety guidelines are crucial for maximizing the benefits of this Cummins part.

-

ElSayed, M. (2017). Fundamentals of Integrated Vehicle Realization. SAE International.

↩ ↩ ↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ ↩ ↩ ↩ ↩ -

Halderman, J. D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩ ↩ ↩ ↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.