This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Studded flange cap screws are vital for the assembly and maintenance of commercial trucks, offering secure fastening solutions essential for the integrity and functionality of various truck systems. The 3941976 Studded Flange Cap Screw by Cummins is particularly notable for its specialized design and application in heavy-duty truck environments.

Basic Concepts

A studded flange cap screw is a fastener with a threaded shank and a flanged head, which distributes the load over a larger area, reducing the risk of the screw pulling through the material it secures. This type is especially useful in applications with vibration and dynamic loads, as the flange maintains a tight connection. The 3941976 model by Cummins is designed with these principles in mind, ensuring robust performance in demanding truck applications 1.

Purpose and Function

The 3941976 Studded Flange Cap Screw is crucial in commercial trucks, used in areas requiring secure fastening to withstand high stress and vibration, such as the engine compartment and transmission housing. It provides a reliable connection point for components subject to significant mechanical stress 2.

Key Features

Crafted from high-strength materials, the 3941976 Studded Flange Cap Screw ensures durability and resistance to wear. Its design includes a hexagonal head for easy tightening with standard tools and a flange that enhances the screw’s ability to resist pull-out. The screw’s threading is precise, allowing for a secure fit that minimizes the risk of loosening over time. Additionally, the screw’s surface may be treated to resist corrosion, extending its service life in harsh environments 3.

Benefits

Using the 3941976 Studded Flange Cap Screw in truck operations offers enhanced durability, reliability, and efficiency. Its robust construction and design features contribute to the overall stability and performance of truck systems. The screw’s ability to maintain a secure connection under dynamic conditions helps prevent component failure and reduces the need for frequent maintenance, leading to more efficient truck operations 4.

Troubleshooting and Maintenance

Common issues with studded flange cap screws may include loosening due to vibration, corrosion, or damage from over-tightening. Regular inspections are recommended to ensure screws are properly torqued and show no signs of wear or corrosion. Maintenance practices should include cleaning the screw and surrounding area, applying an appropriate lubricant if necessary, and replacing screws that show signs of damage or excessive wear. Proper torque settings should be followed to avoid over-tightening, which can lead to screw or component damage.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles.

Studded Flange Cap Screw 3941976 in Cummins Engines

The Studded Flange Cap Screw 3941976, manufactured by Cummins, is a critical component used in various Cummins engines. This part is designed to secure flanges, ensuring a tight and reliable seal, which is essential for maintaining engine integrity and performance.

Engines Utilizing 3941976

ISB Series

- ISB CM2150

- ISB CM550

- ISB4.5 CM2350 B104

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

The ISB series engines benefit from the 3941976 screw in their flange connections, ensuring robust sealing and structural integrity.

ISC Series

- ISC CM2150

- ISC CM850

In the ISC series, the 3941976 screw is used to secure flanges, maintaining the necessary seals and structural connections.

ISF Series

- ISF2.8 CM2220 F129

- ISF3.8 CM2220 AN

- ISF3.8 CM2350 F109

- ISF4.5 CM2220 F123

The ISF series engines incorporate the 3941976 screw to ensure flanges are tightly secured, crucial for the engine’s operational efficiency.

ISM Series

- ISM CM570/870

The ISM series engines use the 3941976 screw in their flange connections, providing the necessary sealing and structural support.

ISX Series

- ISX CM570

The ISX series engine utilizes the 3941976 screw to secure flanges, ensuring optimal sealing and structural integrity.

B Series

- B4.5 CM2350 B129B

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

The B series engines incorporate the 3941976 screw to secure flanges, ensuring the engine’s flanges are tightly sealed and structurally sound.

C GAS PLUS Series

- C GAS PLUS CM556

The C GAS PLUS series engine uses the 3941976 screw to secure flanges, maintaining the necessary seals and structural connections.

F Series

- F2.8 CM2620 F135B

- F3.8 CM2620 F137B

The F series engines utilize the 3941976 screw to secure flanges, ensuring the engine’s flanges are tightly sealed and structurally sound.

ISL Series

- ISL CM2150

- ISL9 CM2150 SN

- ISL9.5 CM2880 L138

The ISL series engines incorporate the 3941976 screw to secure flanges, ensuring optimal sealing and structural integrity.

ISG Series

- ISG12 G CMOH6.0 G111

The ISG series engine uses the 3941976 screw to secure flanges, maintaining the necessary seals and structural connections.

The 3941976 Studded Flange Cap Screw is a versatile and essential component in Cummins engines, ensuring flanges are securely fastened and maintaining the engine’s operational efficiency.

Role of Part 3941976 Studded Flange Cap Screw in Engine Systems

The 3941976 studded flange cap screw is an essential component in various engine systems, providing secure fastening and reliable performance across multiple applications. Its role can be observed in the following systems:

Air Compressor and Air Compressor Kit

In air compressor systems, the 3941976 studded flange cap screw ensures the secure attachment of components, maintaining the integrity of the air compressor kit. It plays a significant role in fastening the air intake connection, ensuring a stable and leak-free setup at the air intake connection location.

Belt Tensioner and Crankcase Breather

For the belt tensioner, this screw provides the necessary tension and stability required for optimal belt performance. In the crankcase breather system, it secures components, allowing for effective ventilation and pressure regulation within the cylinder block.

Cylinder Block Plumbing and Electronic Control Module Wiring Harness

Within the cylinder block plumbing, the 3941976 screw ensures that all plumbing connections are tightly sealed, preventing leaks and ensuring efficient fluid flow. For the electronic control module wiring harness, it secures wiring connections, ensuring reliable electrical conductivity and system performance.

Engine Control Module and Exhaust Recirculation

In the engine control module (ECM), this screw fastens critical components, ensuring the ECM operates within specified parameters. In exhaust recirculation systems, it secures both air and water plumbing, maintaining efficient recirculation and reducing emissions.

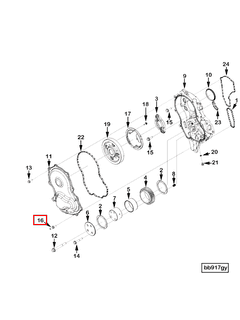

Front Gear Cover and Front Gear Housing

The screw is instrumental in fastening the front gear cover and front gear housing, ensuring these components remain securely in place during engine operation. This is vital for the smooth functioning of the gear system.

Fuel System Components

In the fuel system, the 3941976 screw is used in fuel drain plumbing, fuel filter location fastening, and overall fuel plumbing. It ensures that fuel lines are securely connected, preventing leaks and maintaining fuel system integrity. Additionally, it secures the fuel transfer pump, ensuring stable fuel delivery.

Oil Pan and Turbocharger Plumbing

For the oil pan, this screw ensures that the pan is securely attached, preventing oil leaks. In turbocharger plumbing, it fastens connections, ensuring that the turbocharger operates efficiently without fluid leaks.

Water Outlet Connection and Water Pump

Finally, in the water outlet connection and water pump systems, the 3941976 screw ensures that all water plumbing connections are secure. This is essential for maintaining coolant flow and engine temperature regulation.

Overall, the 3941976 studded flange cap screw plays a significant role in ensuring the secure fastening of various components across multiple engine systems, contributing to the overall reliability and performance of the engine.

Conclusion

The 3941976 Studded Flange Cap Screw by Cummins is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its robust design, high-strength materials, and specialized features make it an indispensable part in ensuring the secure fastening of various components across multiple engine systems. The screw’s ability to maintain a tight and reliable connection under dynamic conditions contributes to the overall reliability, performance, and efficiency of truck operations. Regular maintenance and proper use of this Cummins part are essential to maximize its benefits and ensure the longevity and stability of truck systems.

-

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Gifford, C. (2014). Cars Encyclopedia. DK Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.