This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3942190 Studded Flange Cap Screw is a specialized fastener produced by Cummins, a well-established manufacturer in the commercial truck industry. This component is designed for use in various applications within commercial trucks, ensuring secure and reliable fastening solutions.

Basic Concepts of Studded Flange Cap Screws

A studded flange cap screw is a type of fastener that includes a threaded stud and a flanged head. The stud provides additional length and strength, while the flange offers a larger surface area for distribution of clamping force. This design allows for efficient and secure fastening in applications where standard bolts may not suffice. The screw functions by threading into a corresponding tapped hole, creating a strong and durable connection between components 1.

Role of the 3942190 Studded Flange Cap Screw in Truck Operation

The 3942190 Studded Flange Cap Screw plays a role in the operation and maintenance of commercial trucks by providing a robust fastening solution for various components. It is often used in applications where high strength and reliability are required, such as in engine mounts, transmission housings, and other critical assemblies. Its design ensures that components remain securely fastened, even under significant stress and vibration 2.

Key Features of the 3942190 Studded Flange Cap Screw

The 3942190 Studded Flange Cap Screw is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, typically alloy steel, which provides excellent strength and resistance to wear. The screw features a studded design with a flanged head, allowing for greater clamping force and stability. Additionally, the screw is coated to protect against corrosion, ensuring longevity in various operating environments 3.

Benefits of Using the 3942190 Studded Flange Cap Screw

Using the 3942190 Studded Flange Cap Screw offers several benefits. Its robust construction and design contribute to enhanced durability and reliability in fastening applications. The screw’s ability to distribute clamping force effectively reduces the risk of component failure under stress. Furthermore, its corrosion-resistant coating ensures that it maintains performance over time, even in harsh conditions 4.

Installation Process

Proper installation of the 3942190 Studded Flange Cap Screw is vital for ensuring optimal performance and longevity. The installation process involves several steps: First, ensure that the mating surfaces are clean and free of debris. Next, align the screw with the tapped hole and begin threading it in by hand to avoid cross-threading. Once started, use a torque wrench to tighten the screw to the specified torque setting, ensuring a secure and consistent connection. Finally, inspect the installation to confirm that the screw is properly seated and that there are no signs of damage or misalignment.

Troubleshooting Common Issues

Common issues with the 3942190 Studded Flange Cap Screw may include loosening over time, corrosion, or damage from improper installation. To address these problems, regular inspections should be conducted to identify any signs of wear or corrosion. If loosening is detected, the screw should be re-torqued to the specified setting. In cases of corrosion, the affected area should be cleaned, and a corrosion-resistant coating reapplied if necessary. Damaged screws should be replaced to maintain the integrity of the fastening application.

Maintenance Tips

To prolong the life of the 3942190 Studded Flange Cap Screw, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or loosening. Cleaning the screw and its mating surfaces can prevent the buildup of debris that may contribute to failure. Additionally, ensuring that the screw is properly torqued during installation and re-torqued as needed will help maintain a secure connection.

Compatibility and Applications

The 3942190 Studded Flange Cap Screw is compatible with a range of truck models and is used in various applications within the truck’s components. Its versatility and robust design make it suitable for use in engine mounts, transmission housings, and other critical assemblies where secure fastening is required.

Cummins: A Brief Overview

Cummins is a renowned manufacturer in the commercial truck industry, known for its high-quality engines, components, and aftermarket parts. With a history spanning several decades, Cummins has established a reputation for innovation, reliability, and performance. The company’s product range includes engines, powertrain components, and filtration systems, all designed to meet the demanding requirements of commercial trucking. Cummins’ commitment to quality and customer satisfaction has made it a trusted name in the industry.

Cummins Engine Compatibility with Part 3942190

The Studded Flange Cap Screw, part number 3942190, manufactured by Cummins, is a critical component in the assembly and maintenance of several Cummins engine models. This part is designed to secure flanges and caps, ensuring a tight and reliable connection that is essential for the engine’s operation.

ISB CM550 Engines

The ISB CM550 engines, known for their robust performance and reliability, utilize the Studded Flange Cap Screw in various applications. This part is integral to the engine’s assembly, particularly in securing components that require a high level of precision and durability. The studded design of the screw provides enhanced grip and stability, which is crucial for maintaining the integrity of the engine’s connections under operational stress.

Grouping of Engines

The Studded Flange Cap Screw is not limited to the ISB CM550 engines alone. It is also compatible with other Cummins engine models that share similar design and operational requirements. The commonality in the use of this part across different engine types underscores its versatility and importance in Cummins’ engine architecture.

By ensuring a secure fit and reliable performance, the Studded Flange Cap Screw plays a vital role in the overall functionality and longevity of Cummins engines.

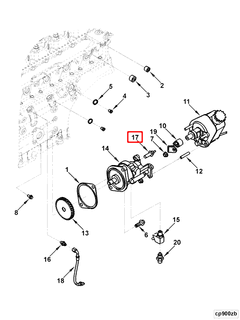

Role of Part 3942190 Studded Flange Cap Screw in Engine Systems

In the intricate world of engine systems, the part 3942190 studded flange cap screw plays a significant role in ensuring the secure assembly and operation of various components. This component is instrumental in the integration and functionality of both pumps and vacuum systems within an engine.

Integration with Pumps

When it comes to pumps, the 3942190 studded flange cap screw is often utilized to fasten critical components such as impellers, housings, and seals. Its design allows for a robust connection that can withstand the dynamic forces and pressures generated during pump operation. This secure fastening is essential for maintaining the alignment and integrity of the pump components, which directly influences the efficiency and reliability of the pump’s performance.

Functionality in Vacuum Systems

In vacuum systems, the 3942190 studded flange cap screw is employed to assemble and secure components like vacuum chambers, valves, and manifolds. The screw’s studded flange provides additional surface area for a tighter seal, which is vital in vacuum applications where even the smallest leaks can significantly impact system performance. By ensuring a secure and leak-free connection, this component helps maintain the vacuum integrity necessary for the precise operation of the system.

Overall Contribution

The 3942190 studded flange cap screw’s role extends beyond mere fastening; it contributes to the overall stability and performance of engine systems. Its application in both pumps and vacuum systems underscores its versatility and importance in ensuring that these components function as intended under various operational conditions.

Conclusion

The 3942190 Studded Flange Cap Screw is a critical component in the commercial truck industry, offering robust fastening solutions for various applications. Its design, featuring a threaded stud and flanged head, ensures secure and reliable connections in demanding environments. The screw’s construction from high-quality materials and its corrosion-resistant coating contribute to its durability and performance. Proper installation and regular maintenance are essential for maximizing the lifespan and effectiveness of this component. As a versatile and reliable fastening solution, the 3942190 Studded Flange Cap Screw plays a vital role in the operation and maintenance of commercial trucks and Cummins engines.

-

Viskup, R. (2020). Diesel and Gasoline Engines. IntechOpen.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.