3944816

Studded Flange Cap Screw

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Studded Flange Cap Screw, Part #3944816, manufactured by Cummins, is a specialized fastener designed for heavy-duty truck applications. Cummins, a renowned name in the automotive industry, is known for its commitment to quality and innovation. This particular screw is significant in ensuring the secure attachment of various components within a truck’s engine or chassis, contributing to the overall reliability and performance of the vehicle.

Basic Concepts and Functionality

A Studded Flange Cap Screw is a type of fastener that combines the features of a stud and a flanged bolt. It operates by threading into a pre-tapped hole, with the flange providing additional surface area for securing components. This design allows for a more robust connection, particularly in applications where vibrations and dynamic loads are common. In the context of heavy-duty trucks, these screws play a role in securing critical components, ensuring they remain firmly in place under various operating conditions 1.

Purpose and Role in Truck Operation

The 3944816 Studded Flange Cap Screw is specifically designed to address the demanding requirements of heavy-duty truck operations. It is used in areas where secure fastening is paramount, such as engine mounts, chassis components, and other critical assemblies. By providing a stable and vibration-resistant connection, this screw contributes to the longevity and reliability of the truck’s mechanical systems 2.

Key Features

The 3944816 Studded Flange Cap Screw boasts several key features that enhance its performance and durability. It is constructed from high-strength materials, ensuring it can withstand the rigors of heavy-duty applications. The screw features a precise threading type that allows for easy installation and removal, while the flange design provides additional security by distributing the load over a larger surface area. Additionally, the screw may include unique attributes such as corrosion-resistant coatings or specialized threading to further improve its functionality in harsh environments 3.

Benefits

Using the 3944816 Studded Flange Cap Screw offers several advantages. Its design provides improved security, making it less likely for components to become loose over time. The screw’s resistance to vibration ensures that connections remain stable, even under dynamic operating conditions. Furthermore, its durability contributes to the longevity of the truck’s components, reducing the need for frequent replacements and maintenance.

Installation and Usage Guidelines

Proper installation of the 3944816 Studded Flange Cap Screw is vital to ensure optimal performance. Begin by ensuring the mating surface is clean and free of debris. Thread the screw into the pre-tapped hole by hand to avoid cross-threading. Use a torque wrench to tighten the screw to the manufacturer’s specified torque settings. It is important to follow these guidelines to prevent over-tightening, which can damage the screw or the component being fastened.

Troubleshooting and Maintenance

Common issues with Studded Flange Cap Screws include loosening due to vibration or corrosion. Regular inspection and maintenance can help identify and address these problems early. If a screw appears loose, it should be re-tightened to the specified torque. In cases of corrosion, the screw may need to be replaced to ensure a secure connection. Keeping the mating surfaces clean and applying an appropriate lubricant can also help prolong the life of the screw.

Safety Considerations

When handling, installing, or maintaining the 3944816 Studded Flange Cap Screw, it is important to follow safety guidelines to prevent accidents. Wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against injury. Ensure that the work area is clean and free of hazards. Follow all torque specifications and installation guidelines to avoid over-tightening, which can lead to component failure. Additionally, be aware of any specific safety instructions provided by Cummins for this part.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality, innovation, and customer satisfaction. The company’s extensive product range includes engines for on-highway and off-highway applications, as well as components and systems that enhance the performance and reliability of vehicles. Cummins’ dedication to excellence is evident in every product they offer, including the 3944816 Studded Flange Cap Screw.

Studded Flange Cap Screw 3944816 in Cummins Engines

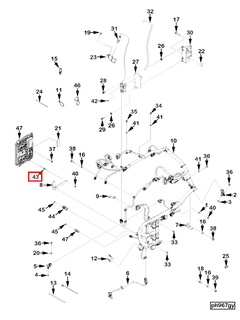

The Studded Flange Cap Screw 3944816, manufactured by Cummins, is a critical component in various Cummins engine models. This screw is integral in securing flanges and ensuring the integrity of the engine’s sealing and structural components. Below is a detailed description of how this part fits within different Cummins engine series:

15N CM2380 M104B Series

The 15N CM2380 M104B engine utilizes the Studded Flange Cap Screw 3944816 to secure the flanges that connect different sections of the engine. This ensures that the engine’s internal components are properly sealed and aligned, maintaining optimal performance and efficiency.

4B3.9, 6B5.9, 6C8.3 Series

In the 4B3.9, 6B5.9, and 6C8.3 engines, the Studded Flange Cap Screw 3944816 is used to fasten various flanges, including those for the exhaust system and coolant passages. This screw’s studded design provides a robust grip, preventing loosening due to vibrations and thermal expansion.

B4.5 CM2350 B129B, B5.6 CM2670 B152B, B6.7 CM2350 B135B, B6.7 CM2670 B153B

The engines in this series, such as the B4.5 CM2350 B129B, B5.6 CM2670 B152B, B6.7 CM2350 B135B, and B6.7 CM2670 B153B, rely on the Studded Flange Cap Screw 3944816 to secure critical flanges. These screws are essential for maintaining the structural integrity of the engine, ensuring that all connections are tight and secure.

F3.8 CM2350 F128C

In the F3.8 CM2350 F128C engine, the Studded Flange Cap Screw 3944816 is used to fasten flanges that are part of the engine’s cooling system. This ensures that the coolant passages are properly sealed, preventing leaks and maintaining the engine’s operational temperature.

ISB Series

The ISB series engines, including ISB (Chrysler), ISB CM2150, ISB CM550, ISB CM850, ISB/ISD4.5 CM2150 B119, ISB/ISD6.7 CM2150 SN, ISB4.5 CM2350 B104, ISB5.9 CM2880 B127, ISB5.9G CM2180, ISB6.7 CM2250, ISB6.7 CM2350 B101, ISB6.7 G CM2180 B118, ISBE CM2150, ISBE4 CM850, ISC CM2150, and ISC CM850, all incorporate the Studded Flange Cap Screw 3944816. This screw is used to secure various flanges throughout the engine, including those for the exhaust, coolant, and other critical systems. The studded design ensures that these connections remain tight, even under the high stresses and vibrations typical of engine operation.

The consistent use of the Studded Flange Cap Screw 3944816 across these engines highlights its importance in maintaining the structural and operational integrity of Cummins engines.

Role of Part 3944816 Studded Flange Cap Screw in Engine Systems

The Part 3944816 Studded Flange Cap Screw is an essential fastening component utilized in various engine systems to ensure secure and reliable connections between different parts. Its applications span across multiple critical areas within the engine, contributing to the overall performance and integrity of the system.

Cam Follower Cover and Cylinder Block

In the arrangement of the cam follower cover and cylinder block, the Studded Flange Cap Screw plays a significant role. It provides the necessary clamping force to maintain a tight seal, preventing oil leaks and ensuring that the cam follower cover remains securely attached to the cylinder block. This is vital for maintaining the lubrication system’s efficiency and protecting internal components from contamination.

Oil Fill and Breather Systems

The oil fill and breather systems are integral to the engine’s lubrication and ventilation. The Studded Flange Cap Screw is used to secure the oil fill cap and breather components to the crankcase. This ensures that the oil fill cap remains sealed, allowing for proper oil level management, while the breather system maintains pressure equilibrium within the crankcase, expelling moisture and contaminants.

Camshaft and Cylinder Head

When assembling the camshaft and cylinder head, the Studded Flange Cap Screw is employed to fasten various covers and housings. This includes securing the camshaft cover, which protects the camshaft and its associated components, and the cylinder head cover, which shields the valvetrain and combustion chambers. Proper fastening is essential to prevent oil leaks and ensure the camshaft and cylinder head operate within specified tolerances.

Front Gear and Electronic Control Module

In the front gear arrangement, the Studded Flange Cap Screw is used to secure the front gear cover, which houses the timing chain or belt and associated sprockets. This ensures the front gear components remain aligned and protected. Additionally, it is utilized in the electronic control module (ECM) assembly to secure the ECM housing, protecting the sensitive electronic components from environmental factors and ensuring reliable operation of the engine control system.

Fuel System Components

Within the fuel system, the Studded Flange Cap Screw is instrumental in securing the fuel filter, fuel gauge, and injector plumbing. It ensures that the fuel filter housing remains intact, preventing fuel leaks and maintaining filtration efficiency. The fuel gauge and injector components are also securely fastened, ensuring accurate fuel measurement and precise fuel delivery to the combustion chambers.

Harness and Wiring

The harness and electronic control module wiring are critical for the engine’s electrical system. The Studded Flange Cap Screw is used to secure various harness connectors and ECM wiring terminals, ensuring a robust and reliable electrical connection. This is essential for the proper functioning of the engine control system and various sensors.

Short Block Kit

In the context of a short block kit, the Studded Flange Cap Screw is used to assemble and secure various components within the kit. This includes fastening the cylinder block, crankcase, and associated covers, ensuring a solid and leak-free assembly. The secure fastening of these components is fundamental to the short block kit’s performance and durability.

Air Intake Manifold and Performance Parts

The air intake manifold and performance parts also benefit from the use of the Studded Flange Cap Screw. It is used to secure the manifold to the cylinder head, ensuring a tight seal for optimal airflow. Additionally, it is employed in the installation of performance parts, such as side oil catch systems, to ensure these components are securely mounted and function as intended.

Conclusion

In summary, the Part 3944816 Studded Flange Cap Screw is a versatile and reliable fastening solution across various engine systems, contributing to the secure assembly and efficient operation of critical components. Its robust design and high-strength materials make it an essential component in maintaining the structural and operational integrity of Cummins engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.