3944874

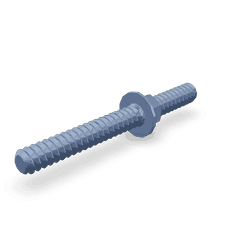

Studded Flange Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3944874 Studded Flange Cap Screw by Cummins is a specialized fastener designed for heavy-duty truck applications. Its purpose is to provide secure fastening in environments where high stress and vibration are common. This screw is significant due to its robust design and reliable performance, which contribute to the overall durability and safety of truck components.

Basic Concepts of Studded Flange Cap Screws

Studded flange cap screws are a type of fastener that includes a threaded shank and a flange at one end. The flange serves to distribute the load more evenly across the surface it contacts, reducing the risk of damage to the material being fastened. These screws are commonly used in mechanical applications where a high degree of fastening security is required. They function by threading into a corresponding nut or directly into a tapped hole, creating a strong and stable connection 1.

Purpose and Role in Truck Operation

In the operation of a truck, the 3944874 Studded Flange Cap Screw plays a specific role in securing various components. It is often used in applications where components are subjected to significant stress or vibration, such as in the engine compartment or chassis. By providing a secure and stable connection, this screw helps maintain the structural integrity of the truck, ensuring that components remain firmly in place under operating conditions 2.

Key Features

The 3944874 Studded Flange Cap Screw features several key attributes that enhance its performance. It is typically made from high-strength materials, such as alloy steel, to withstand the rigors of heavy-duty use. The threading type is designed to provide a strong grip, while the flange design helps distribute the load and prevent loosening. Additionally, the screw may have unique attributes such as a corrosion-resistant coating to improve durability in harsh environments.

Benefits

Using the 3944874 Studded Flange Cap Screw offers several benefits. Its durable material composition and robust design contribute to improved longevity and reliability. The secure fastening provided by the screw helps prevent components from loosening over time, even in high-vibration environments. Furthermore, its resistance to corrosion ensures that it maintains its performance in various weather conditions, enhancing the overall durability of the truck.

Installation Guidelines

Proper installation of the 3944874 Studded Flange Cap Screw is vital to ensure optimal performance. Begin by cleaning the installation area to remove any debris or contaminants. Thread the screw into the corresponding nut or tapped hole by hand to avoid cross-threading. Use a torque wrench to tighten the screw to the manufacturer’s specified torque settings. This ensures that the screw is securely fastened without over-tightening, which could damage the threads or the material being fastened.

Troubleshooting and Maintenance

Common issues with studded flange cap screws include loosening due to vibration and corrosion. To troubleshoot these problems, regularly inspect the screws for signs of wear or damage. If a screw appears loose, re-tighten it to the specified torque settings. To prevent corrosion, apply a protective coating or use screws with a corrosion-resistant finish. Regular maintenance, such as cleaning and inspecting the screws, can help prolong their lifespan and ensure continued reliable performance.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for quality and innovation in the automotive and heavy-duty truck industry. The company offers a wide range of products designed to meet the demanding requirements of various applications, including heavy-duty trucks. Cummins’ commitment to excellence and customer satisfaction has established it as a trusted name in the industry.

Compatibility with Cummins Engines

The Studded Flange Cap Screw, part number 3944874, manufactured by Cummins, is a critical component in the assembly and maintenance of various Cummins engines. This part is designed to secure flanges, ensuring a tight and reliable connection that is essential for the proper functioning of the engine.

ISB Series Engines

The ISB series engines, which include the ISB (Chrysler), ISB CM850, ISB4.5 CM2350 B104, ISB5.9G CM2180, ISX12 CM2350 X102, ISX12 G CM2180 EJ, ISX12/ISX11.9 CM2250, ISX15 CM2250, and ISX15 CM2350 X101, all utilize the Studded Flange Cap Screw in their construction. These engines are known for their robust design and are used in a variety of applications, from heavy-duty trucks to industrial machinery. The screw’s role in these engines is to maintain the integrity of flange connections, which are crucial for sealing and preventing leaks.

ISC Series Engines

Similarly, the ISC series engines, including the ISC CM2150, ISC CM554, ISC CM850, ISC8.3 CM2250, ISL CM2150, ISL CM554, ISL G CM2180, ISL9 CM2150 SN, ISL9 CM2250, ISL9.5 CM2880 L138, and ISM CM876, also incorporate the Studded Flange Cap Screw. These engines are designed for a range of applications, from agricultural equipment to marine vessels. The screw’s function in these engines is to ensure that flanges are securely fastened, which is vital for maintaining the engine’s performance and longevity.

L GAS PLUS Series Engine

The L GAS PLUS CM556 engine, which is part of the L series, also utilizes the Studded Flange Cap Screw. This engine is designed for use in natural gas applications, providing a cleaner and more efficient alternative to traditional fuel sources. The screw’s role in this engine is to maintain the secure connection of flanges, which is essential for the safe and efficient operation of the engine.

B Series Engines

The B series engines, including the B4.5 CM2350 B129B, B6.7 CM2670 B153B, and F3.8 CM2350 F128C, also rely on the Studded Flange Cap Screw. These engines are known for their versatility and are used in a variety of applications, from construction equipment to power generation. The screw’s function in these engines is to ensure that flanges are tightly secured, which is crucial for maintaining the engine’s efficiency and reliability.

Role of Part 3944874 Studded Flange Cap Screw in Engine Systems

The 3944874 Studded Flange Cap Screw is integral in securing various components within engine systems, ensuring stability, proper function, and efficient operation. Its application spans across multiple subsystems, each playing a vital role in the overall performance of the engine.

Aftertreatment Arrangement

In the aftertreatment arrangement, the 3944874 screw is used to fasten components such as the fluid doser and exhaust recirculation (EGR) system. This ensures that these parts remain securely in place, allowing for precise control of emissions and efficient aftertreatment processes.

Air Intake Manifold

Within the air intake manifold, the screw helps in attaching the manifold to the engine block. This secure attachment is essential for maintaining airtight seals, which are necessary for optimal air-fuel mixture and engine performance.

Crankcase Breather

The crankcase breather system relies on the 3944874 screw to attach the breather housing to the engine. This connection is important for venting crankcase gases, preventing pressure build-up, and maintaining engine lubrication integrity.

Engine Control Module (ECM)

For the ECM, the screw is utilized in mounting the module to its bracket. Secure attachment of the ECM ensures that it remains protected from vibrations and environmental factors, contributing to reliable engine control and diagnostics.

Engine Oil Cooler

In the engine oil cooler setup, the screw is employed to fasten the cooler to the engine block or mounting bracket. This secure fit is vital for efficient heat exchange, which helps in maintaining optimal oil temperature and engine longevity.

Exhaust Recirculation Air Plumbing

The EGR air plumbing system uses the 3944874 screw to connect various pipes and fittings. This ensures a leak-free system, allowing for effective recirculation of exhaust gases to reduce nitrogen oxides (NOx) emissions.

Fuel Filter Location and Mounting

At the fuel filter location, the screw is critical in mounting the filter housing to the engine or frame. This secure attachment prevents fuel leaks and ensures consistent fuel delivery to the injectors.

Fuel Shutoff Valve

The fuel shutoff valve is another component where the screw plays a key role. It ensures that the valve is firmly attached, allowing for reliable operation in stopping fuel flow when necessary, which is important for safety and engine protection.

Hardware Kit

In hardware kits, the 3944874 screw is often included for various fastening applications. Its versatility makes it suitable for securing a wide range of engine components, from sensors to brackets.

Injector Plumbing

For injector plumbing, the screw is used to secure injector lines and fittings. This ensures that the fuel delivery system remains intact, providing consistent fuel pressure and flow to the injectors.

Intake Assembly Connection

The intake assembly connection benefits from the use of the 3944874 screw to attach the intake manifold to the cylinder head. This secure connection is essential for maintaining proper air intake and engine sealing.

Lubricating Oil Filter Kit

In the lubricating oil filter kit, the screw is used to attach the oil filter housing to the engine. This ensures a tight seal, preventing oil leaks and maintaining efficient filtration.

Oil Filter Cooler Head

The oil filter cooler head assembly uses the screw to secure the cooler to the engine or mounting bracket. This attachment is important for effective oil cooling, which helps in prolonging engine life.

Turbocharger Arrangement

Finally, in the turbocharger arrangement, the screw is utilized to fasten the turbocharger to the engine and exhaust system. This secure fit is essential for maintaining turbocharger efficiency and preventing leaks in the exhaust system.

Conclusion

The 3944874 Studded Flange Cap Screw by Cummins is a critical component in the assembly and maintenance of various Cummins engines. Its robust design and reliable performance contribute to the overall durability and safety of truck components. Proper installation and regular maintenance of this screw are essential to ensure optimal performance and longevity of the engine systems it supports.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.