3954857

Studded Flange Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Studded Flange Cap Screw Part #3954857 is a specialized fastener produced by Cummins, a well-established manufacturer in the commercial truck industry. This component is designed for use in various mechanical assemblies within commercial trucks, ensuring secure and reliable connections.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that includes a threaded stud and a flanged head. It is commonly used in mechanical assemblies to provide a secure connection between components. The flanged head distributes the load over a larger area, reducing the risk of damage to the connected parts. Within a system, it plays a role by maintaining the integrity of the assembly under various operational conditions 1.

Purpose and Role in Truck Operation

The Studded Flange Cap Screw Part #3954857 is utilized in commercial trucks for applications that require robust and durable fastening solutions. It is often found in engine components, transmission systems, and chassis assemblies. Its role is to ensure that critical parts remain securely attached, contributing to the overall reliability and performance of the truck.

Key Features

The Studded Flange Cap Screw Part #3954857 is crafted from high-strength materials, ensuring durability and resistance to wear. Its design includes a flanged head that provides additional surface area for load distribution, enhancing the security of the connection. The screw is also treated to resist corrosion, making it suitable for use in harsh environments typical of commercial truck operations.

Benefits

Using the Studded Flange Cap Screw Part #3954857 offers several advantages. Its high-strength material composition ensures longevity and reliability under demanding conditions. The flanged design enhances the stability of the connection, reducing the likelihood of loosening over time. Additionally, its corrosion-resistant treatment prolongs the component’s service life, even in challenging environments.

Installation Process

To install the Studded Flange Cap Screw Part #3954857, begin by ensuring the mating surfaces are clean and free of debris. Use a torque wrench to tighten the screw to the manufacturer’s specified torque settings, ensuring a secure fit without over-tightening. It is advisable to apply a thread locker to the threads to prevent loosening due to vibrations. Follow best practices for tightening sequences to maintain even pressure across the flange.

Troubleshooting Common Issues

Common issues with studded flange cap screws include loosening due to vibrations and corrosion. To address loosening, inspect the screw and ensure it is tightened to the correct torque specification. Applying a thread locker can help prevent future loosening. For corrosion, regular inspection and cleaning of the screw and surrounding areas can mitigate issues. In cases of severe corrosion, replacement of the screw may be necessary.

Maintenance Tips

Regular maintenance of the Studded Flange Cap Screw Part #3954857 involves periodic inspection for signs of wear, corrosion, or loosening. Clean the screw and surrounding areas to remove any buildup that could affect performance. Re-torque the screw as per the manufacturer’s recommendations during routine maintenance checks to ensure it remains securely fastened.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality and reliability in the commercial truck industry. Their product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations 2.

Application of Studded Flange Cap Screw Part 3954857 in Cummins Engines

The Studded Flange Cap Screw part number 3954857, manufactured by Cummins, is a critical component in the assembly and maintenance of various Cummins engine models. This part is integral to securing flanges and ensuring the integrity of the engine’s sealing and structural components. Below is a detailed description of its application across different engine series.

ISB Series

- ISB CM850: The Studded Flange Cap Screw is used in the ISB CM850 engine to secure various flanges, ensuring a tight seal and proper alignment of components.

- ISB6.7 CM2350 B101: This engine utilizes the part to maintain the structural integrity of the exhaust system and other critical flanges.

ISC Series

- ISC CM2150: The screw is employed to secure flanges in the ISC CM2150 engine, ensuring that connections remain tight and leak-free.

- ISC8.3 CM2250: Similar to the ISC CM2150, this engine also uses the Studded Flange Cap Screw to maintain the integrity of its flange connections.

ISL Series

- ISL CM2150: In the ISL CM2150 engine, the part is used to secure flanges, contributing to the overall reliability and performance of the engine.

- ISL9 CM2250: This engine model also relies on the Studded Flange Cap Screw to ensure that flanges are properly secured and aligned.

ISM Series

- ISM CM570/870: The screw is used in the ISM CM570/870 engine to secure various flanges, ensuring that the engine operates efficiently and reliably.

- ISM CM876: This engine model also employs the Studded Flange Cap Screw to maintain the structural integrity of its flange connections.

- ISM11 CM876 SN: The part is used in this engine to secure flanges, ensuring that the engine’s components remain properly aligned and sealed.

ISX Series

- ISX15 CM2250 SN: The Studded Flange Cap Screw is used in the ISX15 CM2250 SN engine to secure flanges, ensuring that the engine operates efficiently and reliably.

- ISX15 CM2350 X101: This engine model also relies on the part to maintain the integrity of its flange connections.

QSC and QSL Series

- QSC9 CM2250/QSL9 CM2250: The screw is used in these engines to secure flanges, ensuring that the engine operates efficiently and reliably.

- QSL9 CM2250: This engine model also employs the Studded Flange Cap Screw to maintain the structural integrity of its flange connections.

- QSL9 CM2350 L102: The part is used in this engine to secure flanges, ensuring that the engine’s components remain properly aligned and sealed.

QSM and QSX Series

- QSM11 CM876: The screw is used in the QSM11 CM876 engine to secure flanges, ensuring that the engine operates efficiently and reliably.

- QSX15 CM2250: This engine model also relies on the Studded Flange Cap Screw to maintain the integrity of its flange connections.

- QSX15 CM2250 ECF: The part is used in this engine to secure flanges, ensuring that the engine’s components remain properly aligned and sealed.

- QSX15 CM2350 X105: The screw is used in this engine to secure flanges, ensuring that the engine operates efficiently and reliably.

X Series

- X12 CM2350 X119B: The Studded Flange Cap Screw is used in the X12 CM2350 X119B engine to secure flanges, ensuring that the engine operates efficiently and reliably.

- X15 CM2350 X116B: This engine model also employs the part to maintain the structural integrity of its flange connections.

- X15 CM2350 X123B: The screw is used in this engine to secure flanges, ensuring that the engine’s components remain properly aligned and sealed.

- X15 CM2450 X134B: The part is used in this engine to secure flanges, ensuring that the engine operates efficiently and reliably.

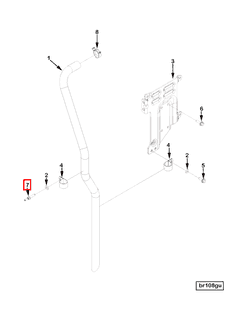

Role of Part 3954857 Studded Flange Cap Screw in Engine Systems

The 3954857 studded flange cap screw is integral to the secure and efficient operation of various engine components. It is commonly employed in the arrangement of the crankcase breather system, ensuring that the breather valve is properly fastened to the valve cover. This secure attachment is vital for maintaining the integrity of the crankcase ventilation, which helps in expelling contaminants and moisture from the crankcase.

In the context of the engine oil cooler, the 3954857 screw plays a role in attaching the cooler to the engine block or other mounting points. This ensures a stable and leak-free connection, which is essential for the efficient transfer of heat away from the engine oil. Proper attachment also prevents any potential oil leaks that could compromise engine performance.

The screw is also utilized in the harness arrangement for the electronic control module wiring and engine control wiring. It secures the wiring harness to the engine or chassis, protecting the wires from vibration and physical damage. This is important for maintaining the reliability of the engine’s electronic systems.

Additionally, the 3954857 screw is employed in the plumbing of the lubricating oil filter head. It ensures that the filter head is tightly secured to the engine block, which is essential for maintaining oil filtration efficiency and preventing oil leaks.

Overall, the 3954857 studded flange cap screw is a versatile fastener that contributes to the secure and efficient operation of multiple engine components, enhancing both performance and reliability.

Conclusion

The Studded Flange Cap Screw Part #3954857 by Cummins is a critical component in the assembly and maintenance of various engine models. Its robust design, high-strength materials, and corrosion-resistant treatment make it suitable for demanding commercial truck operations. Proper installation, maintenance, and troubleshooting are essential to ensure the longevity and reliability of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.