3957063

Studded Flange Cap Screw

Cummins®

IN STOCK

1 is currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

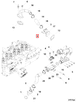

The Studded Flange Cap Screw, identified by Part #3957063, is a specialized fastener produced by Cummins, a renowned manufacturer in the automotive and heavy-duty truck industry. This component is integral to commercial truck applications, where it ensures secure fastenings and contributes to the structural integrity of various assemblies. Cummins, with its reputation for high-quality components, provides this screw as part of its extensive range of automotive parts designed to meet the demanding requirements of commercial vehicles.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener characterized by a threaded stud that extends through a flange, which is a flat, disk-shaped part that enhances the screw’s ability to distribute load and resist loosening. In fastening applications, this screw operates by securing two or more components together, utilizing the threads to create a clamping force when tightened. This mechanism is fundamental in mechanical systems where reliable and durable connections are required 1.

Purpose and Role in Truck Operation

The 3957063 Studded Flange Cap Screw serves a specific purpose in the context of commercial trucks. It is designed to provide secure fastenings in applications where high load-bearing capacity and resistance to vibration are necessary. By ensuring that components remain firmly attached, this screw plays a role in maintaining the structural integrity of the truck, which is vital for safe and efficient operation.

Key Features

The 3957063 Studded Flange Cap Screw features a design that includes a threaded stud and a flange, which enhances its performance and durability. The material composition typically involves high-strength steel, which provides the necessary tensile strength and resistance to wear. Additionally, the screw may have unique attributes such as a corrosion-resistant coating, which further enhances its longevity in harsh operating environments 2.

Benefits

Utilizing the 3957063 Studded Flange Cap Screw offers several advantages. Its high load-bearing capacity ensures that it can withstand the stresses encountered in commercial truck applications. The resistance to corrosion, often provided by a protective coating, allows the screw to maintain its integrity in various environmental conditions. Furthermore, the design of the screw facilitates ease of installation, reducing the time and effort required during assembly.

Installation Process

Proper installation of the 3957063 Studded Flange Cap Screw involves several steps to ensure optimal performance. Begin by aligning the screw with the designated hole in the assembly. Insert the stud through the flange and engage the threads with the corresponding nut or tapped hole. Tighten the screw to the specified torque using a torque wrench to achieve the recommended clamping force without over-tightening, which could damage the threads or the components being fastened 3.

Troubleshooting and Maintenance

Common issues with Studded Flange Cap Screws include loosening due to vibration or corrosion. Regular inspection for signs of wear or damage is recommended to identify potential problems early. Maintenance practices such as applying a thread locker or anti-seize compound can help prevent loosening and corrosion, respectively. If corrosion is detected, cleaning the affected area and reapplying a protective coating may be necessary to prolong the screw’s lifespan.

Safety Considerations

When working with Studded Flange Cap Screws, it is important to observe safety precautions and best practices. Proper handling involves using the appropriate tools to avoid damage to the screw or the components being fastened. Storage should be in a dry, secure location to prevent corrosion. Disposal should comply with local regulations to ensure environmental safety. Always wear personal protective equipment (PPE) when installing or maintaining these screws to mitigate risks and ensure workplace safety.

Cummins Overview

Cummins is a well-established manufacturer with a strong reputation in the automotive industry. Founded with a commitment to innovation and quality, Cummins has consistently delivered high-performance components for commercial vehicles. The company’s dedication to manufacturing excellence is evident in its wide range of products, including the 3957063 Studded Flange Cap Screw, which is designed to meet the rigorous demands of heavy-duty truck applications.

Studded Flange Cap Screw 3957063 Compatibility with Cummins Engines

The Studded Flange Cap Screw part number 3957063, manufactured by Cummins, is a critical component in securing flanges and ensuring a tight seal in various engine systems. This part is designed to fit seamlessly with several Cummins engine models, providing robust and reliable fastening solutions.

Flange Cap Screws in F Series Engines

The F Series engines, including the F2.8 CM2620 F135B, F3.8 CM2350 F128C, F4.5 CM2620 F141C, and F3.8 CM2350 F107, utilize the 3957063 Studded Flange Cap Screw for securing flanges in their exhaust systems. These engines are known for their durability and efficiency, and the use of this specific screw ensures that the flanges remain tightly sealed, preventing leaks and maintaining optimal performance.

Flange Cap Screws in ISB Series Engines

The ISB Series engines, such as the ISB CM850, ISB4.5 CM2350 B104, and ISB6.7 G CM2180 B118, also benefit from the 3957063 Studded Flange Cap Screw. This screw is integral in securing various flanges within the engine’s cooling and exhaust systems. The studded design provides additional grip and stability, which is crucial for maintaining the integrity of the engine’s components under high-stress conditions.

Flange Cap Screws in ISF Series Engines

The ISF Series engines, including the ISF2.8 CM2220 F117 and ISF2.8 CM2220 F129, incorporate the 3957063 Studded Flange Cap Screw in their design. This screw is used to secure flanges in the engine’s exhaust and intake systems, ensuring that these components are tightly fastened and sealed. The studded feature of the screw provides enhanced holding power, which is essential for the longevity and reliability of the engine.

Flange Cap Screws in QSB and QSF Series Engines

The QSB5.9 CM850 and QSF3.8 CM2350 F107 engines also utilize the 3957063 Studded Flange Cap Screw. This screw is crucial for securing flanges in the engine’s exhaust and cooling systems, ensuring that these components are tightly fastened and sealed. The studded design of the screw provides additional grip and stability, which is vital for maintaining the integrity of the engine’s components under high-stress conditions.

Role of Part 3957063 Studded Flange Cap Screw in Engine Systems

The 3957063 studded flange cap screw is an essential component in various engine systems, providing secure fastening and reliable connections. Its application spans across multiple critical areas, ensuring the integrity and functionality of the engine.

Compressor and Air Systems

In compressor systems, the 3957063 screw is utilized to fasten components that manage air compression. This includes securing the compressor housing to its mounting bracket, ensuring stability under high operational pressures. Additionally, in air systems, it plays a role in attaching air filters and ducts, maintaining airtight seals that are vital for efficient air flow and engine performance.

Converter and Catalytic Systems

Within the converter and catalytic systems, the 3957063 screw is employed to secure catalytic converters to the exhaust system. This ensures that the converter remains firmly in place, allowing for effective emission control. It also aids in attaching sensors and monitoring devices to the converter, facilitating accurate readings and system diagnostics.

Module and Fuel Control Systems

In module and fuel control systems, the screw is integral in fastening electronic control modules (ECMs) and fuel injectors. This secure attachment is necessary for the precise operation of fuel delivery systems, ensuring consistent fuel flow and combustion efficiency. Moreover, it helps in mounting fuel pressure regulators and other control components, contributing to overall system reliability.

Mounting and Alternator Systems

For mounting purposes, the 3957063 screw is used to secure various engine components to the engine block or chassis. This includes attaching alternators, which are crucial for generating electrical power. A secure fastening ensures that the alternator operates efficiently without vibrations that could lead to malfunction.

Pan and Oil Systems

In oil systems, the screw is utilized to fasten oil pans and sumps, ensuring that the oil reservoir remains intact and leak-free. It also plays a role in securing oil filters and pressure relief valves, maintaining the integrity of the lubrication system and protecting engine components from wear.

Plumbing and Exhaust Recirculation Air Systems

Within plumbing systems, the 3957063 screw is used to secure hoses and pipes that transport fluids throughout the engine. This includes fastening coolant lines and fuel lines, ensuring that there are no leaks or disconnections. In exhaust recirculation air (ERA) systems, it is employed to attach ERA valves and pipes, facilitating the recirculation of exhaust gases to reduce emissions and improve combustion efficiency.

Conclusion

The 3957063 Studded Flange Cap Screw is a versatile and essential component in various Cummins engine models. Its studded design ensures a secure and tight seal, which is critical for the performance and longevity of the engine. Proper installation, maintenance, and safety considerations are vital to ensure the optimal functionality and durability of this component in commercial truck applications.

-

Kasab, John, and Andrea Strzelec. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩ -

Bonneau, Dominique, Aurelian Fatu, and Dominique Souchet. Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE, 2014.

↩ -

Osgood, Libby, Gayla Cameron, and Emma Christensen. Engineering Mechanics: Statics. Creative Commons, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.