This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

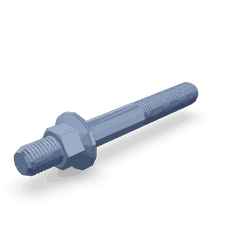

The Studded Flanged Cap Screw, Part #3972984, manufactured by Cummins, is a specialized fastener designed for use in commercial truck applications. Cummins is recognized for its high-quality components that enhance the performance and reliability of commercial vehicles. This part plays a significant role in ensuring the secure assembly of various truck components, contributing to the overall efficiency and durability of the vehicle 1.

Basic Concepts of Studded Flanged Cap Screws

Studded flanged cap screws are characterized by a threaded shank and a flanged head, which provides additional surface area for torque application. These screws are commonly used in mechanical applications where a secure and robust connection is required. The flanged head aids in tightening and helps distribute the load more evenly across the surface, reducing the risk of damage to the material being fastened 2.

Purpose and Role in Truck Operation

This Cummins part is specifically designed for use in commercial trucks. Its primary role is to provide a secure fastening solution for components that are subject to significant stress and vibration. By ensuring that parts remain firmly in place, this screw contributes to the overall functionality and reliability of the truck. It is often used in applications where the connection must withstand high loads and dynamic forces, such as in the engine compartment or chassis assembly 3.

Key Features

The 3972984 features a robust design that includes a threaded shank and a flanged head. The screw is typically made from high-strength materials, such as alloy steel, which provides excellent durability and resistance to wear. The flanged head is designed to offer a larger surface area for torque application, enhancing the screw’s fastening capabilities. Additionally, the screw may include features such as a corrosion-resistant coating to extend its lifespan in harsh environments 4.

Benefits

Using the 3972984 offers several benefits. Its high-strength material composition ensures improved durability, making it suitable for applications where the fastener is subject to significant stress. The flanged head provides enhanced fastening capabilities, allowing for secure and reliable connections. Furthermore, the screw’s resistance to wear and corrosion helps prolong its lifespan, reducing the need for frequent replacements and maintenance 5.

Installation Guidelines

Proper installation of the 3972984 is crucial for ensuring optimal performance. To install the screw, first, ensure that the mating surfaces are clean and free of debris. Use a torque wrench to tighten the screw to the specified torque value, which can typically be found in the manufacturer’s guidelines. It is important to avoid over-tightening, as this can lead to damage to the screw or the material being fastened. Additionally, ensure that the screw is installed in the correct orientation, with the flanged head facing the appropriate direction for maximum effectiveness 6.

Troubleshooting and Maintenance

Common issues with studded flanged cap screws may include loosening over time due to vibration or wear. To identify these problems, regularly inspect the screws for signs of movement or damage. If a screw appears loose, it should be re-tightened to the specified torque value. Additionally, check for any signs of corrosion or wear on the screw and the mating surfaces. Regular maintenance, such as cleaning and lubricating the screw, can help prolong its lifespan and ensure continued reliable performance 7.

Compatibility and Applications

The 3972984 is commonly used in various applications within commercial trucks. It is often found in the engine compartment, where it secures components such as engine mounts or brackets. Additionally, it may be used in the chassis assembly to fasten parts that are subject to significant stress and vibration. Its robust design and high-strength material make it suitable for a wide range of applications where a secure and durable fastening solution is required 8.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer in the automotive industry, with a long-standing reputation for producing high-quality components. Founded in 1919, Cummins has a history of innovation and excellence, providing reliable and durable parts for a variety of applications. The company is committed to delivering products that meet the demanding requirements of commercial vehicles, ensuring that they operate efficiently and reliably. Cummins’ dedication to quality and performance is evident in their wide range of automotive components, including the Studded Flanged Cap Screw Part #3972984 9.

Role of Part 3972984 Studded Flanged Cap Screw in Engine Systems

The 3972984 is integral to the secure assembly and operation of various engine components. Its primary function is to provide a robust fastening solution that ensures components remain firmly in place under the dynamic and often harsh conditions within an engine system.

Component Integration

-

Arrangement: The studded flanged cap screw plays a significant role in the precise arrangement of engine components. It ensures that parts are correctly aligned and secured, which is essential for the efficient operation of the engine. Proper arrangement is vital for maintaining the structural integrity and performance of the engine.

-

Oil Fill: In the oil fill system, the studded flanged cap screw is used to secure the oil fill cap. This ensures that the cap remains tightly sealed, preventing oil leaks and maintaining the proper oil level within the engine. Consistent oil levels are necessary for lubrication and cooling, which are critical for engine longevity and performance.

-

Cover: The screw is often employed to fasten various covers within the engine, such as the valve cover or timing cover. These covers protect internal components from debris and contaminants. Secure fastening prevents the covers from becoming dislodged, which could lead to damage or failure of the protected components.

-

Hand Hole: Hand holes are essential for accessing certain parts of the engine for maintenance or repair. The studded flanged cap screw ensures that hand hole covers are securely attached, allowing technicians to safely and effectively perform necessary tasks without the risk of covers becoming loose or detached.

-

Harness: Wiring harnesses are vital for the electrical systems within the engine. The screw is used to secure harnesses in place, ensuring they do not move or become damaged during engine operation. This is important for maintaining the integrity of the electrical connections and the overall functionality of the engine’s electronic systems.

-

Electronic Control Module (ECM) Wiring: The ECM is a central component in modern engines, controlling various functions through electronic signals. The studded flanged cap screw is used to secure ECM wiring and related components, ensuring that connections remain stable and reliable. This is essential for the accurate and consistent operation of the ECM and the engine as a whole.

Conclusion

In summary, the studded flanged cap screw is a versatile and essential component in the assembly and maintenance of engine systems. Its role in securing various parts ensures the engine operates efficiently and reliably, highlighting the importance of proper fastening in mechanical systems.

-

Alma Hillier, Fundamentals of Motor Vehicle Technology Book 1 6th Edition, Oxford University Press, 2014.

↩ -

Nigel Calder, Diesel Engine Care and Repair, The McGraw-Hill Companies, 2007.

↩ -

John C Dixon, Tyres Suspension and Handling Second Edition, SAE International, 1996.

↩ -

Cummins, Operation and Maintenance Manual, Bulletin Number 5579936, B5.9 CM2670 B166C.

↩ -

Cummins, Operation and Maintenance Manual, Bulletin Number 5579936, B5.9 CM2670 B166C.

↩ -

Cummins, Operation and Maintenance Manual, Bulletin Number 5579936, B5.9 CM2670 B166C.

↩ -

Cummins, Operation and Maintenance Manual, Bulletin Number 5579936, B5.9 CM2670 B166C.

↩ -

Cummins, Operation and Maintenance Manual, Bulletin Number 5579936, B5.9 CM2670 B166C.

↩ -

Cummins, Operation and Maintenance Manual, Bulletin Number 5579936, B5.9 CM2670 B166C.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.