4336706

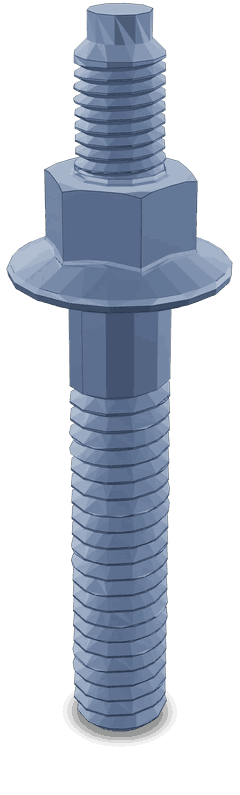

Studded Flange Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 4336706 Studded Flange Cap Screw is a specialized fastener produced by Cummins, a leading manufacturer in the commercial truck industry. This component is designed for use in commercial trucks, where it plays a role in securing various mechanical components. Its robust design and high-quality materials make it suitable for the demanding conditions encountered in truck operations 3.

Basic Concepts of Studded Flange Cap Screws

Studded flange cap screws are a type of fastener that combines the features of a stud and a flanged bolt. They are commonly used in mechanical systems to secure components that require a high degree of stability and resistance to vibration. The studded design allows for easy installation and removal, while the flange provides additional surface area for load distribution and prevents the screw from turning when tightened 1.

Role of the 4336706 Studded Flange Cap Screw in Truck Operation

In commercial trucks, this Cummins part is used in various applications where secure fastening is required. It is often found in engine components, transmission systems, and chassis assemblies. The screw helps maintain structural integrity by ensuring that critical parts remain firmly attached, even under the dynamic loads and vibrations experienced during truck operation 3.

Key Features of the 4336706 Studded Flange Cap Screw

The 4336706 is characterized by several key features that enhance its functionality and durability. It is made from high-strength materials, typically alloy steel, which provides excellent resistance to wear and corrosion. The threading type is designed to offer a secure grip, while the flange design distributes loads more effectively and prevents rotation during tightening. Additionally, the screw may feature unique attributes such as a corrosion-resistant coating or specialized threading to further improve performance 2.

Benefits of Using the 4336706 Studded Flange Cap Screw

Using this part offers several benefits. Its design allows for improved load distribution, which reduces stress on the fastened components. The flange enhances security by preventing the screw from loosening over time, even in high-vibration environments. Furthermore, the material and design contribute to increased resistance to corrosion and wear, ensuring long-term reliability 3.

Installation and Usage Guidelines

Proper installation of the 4336706 is vital for optimal performance. It is recommended to use the appropriate torque specifications provided by Cummins to ensure the screw is tightened to the correct level without over-tightening, which could lead to damage. Using the recommended tools, such as a torque wrench, will help achieve the desired tightness. Best practices include cleaning the installation area to remove any debris that could affect the screw’s performance and ensuring that all components are properly aligned before tightening 3.

Troubleshooting Common Issues

Common issues with studded flange cap screws include corrosion, stripping, and loosening. Corrosion can be addressed by applying a protective coating or using screws made from corrosion-resistant materials. Stripping may occur if the screw is over-tightened; using the correct torque specifications can prevent this. If loosening is detected, it may be necessary to re-tighten the screw or replace it if damage is present. Regular inspections can help identify these issues early, allowing for timely maintenance 3.

Maintenance Recommendations

Regular maintenance of the 4336706 is important to ensure continued reliability and safety. Inspection intervals should be established based on the truck’s usage and operating conditions. Cleaning the screw and surrounding area can prevent the buildup of dirt and debris that could affect performance. If signs of wear or damage are observed, the screw should be replaced to maintain the integrity of the fastened components 3.

Cummins: A Brief Overview

Cummins Inc. is a globally recognized manufacturer with a strong presence in the commercial truck industry. The company has a history of innovation and quality, producing a wide range of components and systems for trucks and other heavy-duty applications. Cummins is known for its commitment to developing reliable and high-performance parts, such as the 4336706, which contribute to the efficiency and durability of commercial vehicles 3.

Studded Flange Cap Screw in Cummins Engines

The Studded Flange Cap Screw, part number 4336706, is a critical component in several Cummins engine models. This part is integral to the assembly and maintenance of the following engines:

ISX CM570 and ISX CM870

In the ISX CM570 and ISX CM870 engines, the Studded Flange Cap Screw is used in various applications to secure flanges and other components. Its robust design ensures reliable fastening, which is crucial for maintaining the integrity of the engine’s structure and performance.

ISX CM871

Similar to its counterparts, the ISX CM871 engine also utilizes the Studded Flange Cap Screw for securing flanges. This screw’s studded feature provides additional grip and stability, which is essential in high-stress environments typical of heavy-duty engines.

ISX15 CM2250

The ISX15 CM2250 engine incorporates the Studded Flange Cap Screw in its design to ensure that all flanged components are securely fastened. This is particularly important in maintaining the engine’s operational efficiency and longevity.

Grouping of Engines

The ISX CM570, ISX CM870, and ISX CM871 engines share many common features and design principles, making the Studded Flange Cap Screw a versatile component across these models. The ISX15 CM2250, while part of the same family, represents a more advanced iteration with enhanced capabilities and performance metrics. Despite these differences, the fundamental role of the Studded Flange Cap Screw remains consistent across all these engines.

Role of Part 4336706 Studded Flange Cap Screw in Engine Systems

In the intricate network of an engine system, the 4336706 serves as a pivotal fastening component. It is integral in securing various assemblies and ensuring the structural integrity and operational efficiency of the engine.

Lever and Rocker Mechanisms

The 4336706 is employed in the assembly of levers and rockers, which are fundamental in translating motion within the engine. These components often require precise alignment and secure attachment to function correctly. The screw’s design allows for a robust connection, minimizing the risk of displacement or failure under the dynamic conditions of engine operation.

Rocker Lever Assembly

Within the rocker lever assembly, the 4336706 plays a significant role. This assembly is responsible for transferring motion from the camshaft to the valves, a process that demands exactitude and reliability. The screw ensures that the components of the rocker lever assembly remain firmly in place, facilitating smooth and consistent valve operation.

Rocker Lever Top Level Assembly

In the rocker lever top level assembly, the 4336706 contributes to maintaining the assembly’s stability. This top-level assembly often includes additional components that require secure fastening to prevent any form of misalignment or movement that could affect the engine’s performance. The screw’s studded flange provides enhanced grip and resistance to vibrational forces, ensuring that the assembly operates within specified parameters.

Conclusion

Overall, the 4336706 Studded Flange Cap Screw is a key component in the securement and stability of various engine assemblies, playing a significant role in the reliable operation of the engine system. Its robust design, high-quality materials, and specialized features make it an essential part for maintaining the structural integrity and performance of Cummins engines.

-

Charging the Internal Combustion Engine, Hermann Hiereth, Peter Prenninger and Klaus W Drexl, Springer, 2010

↩ -

Synthesis Lectures on Advances in Automotive Technology, Amir Khajepour, Springer, 2023

↩ -

Heavy Duty Truck Systems Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011

↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.