This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

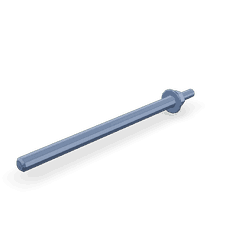

The Studded Flange Cap Screw, Part #4892989 by Cummins, is a specialized fastener designed for heavy-duty truck applications. Cummins, a renowned manufacturer in the automotive industry, produces this component to meet the demanding requirements of truck mechanics and operators. This screw is integral to ensuring the structural integrity and performance of heavy-duty trucks 1.

Basic Concepts of Studded Flange Cap Screws

A Studded Flange Cap Screw is a type of fastener that includes a threaded stud and a flanged head. The stud provides a continuous thread that can be secured with a nut, while the flange offers additional surface area for load distribution and resistance to rotation. This design allows for secure fastening in applications where high loads and vibrations are common. Within a truck’s mechanical system, these screws are used to join components that require robust and reliable connections 2.

Role and Function in Truck Operation

The 4892989 Studded Flange Cap Screw plays a significant role in the operation of a truck by securing critical components that are subject to high stress and vibration. It is commonly used in areas such as engine mounts, transmission housings, and chassis components. By providing a secure and stable connection, this screw helps maintain the structural integrity and performance of the truck, ensuring that components remain firmly in place under various operating conditions 3.

Key Features

The 4892989 Studded Flange Cap Screw boasts several key features that enhance its performance and durability. It is made from high-strength materials, typically alloy steel, which provides excellent tensile strength and resistance to wear. The threading type is designed to offer a tight and secure fit, while the flange design distributes loads more effectively and prevents the screw from rotating during tightening. Additionally, the screw may feature coatings or treatments that provide resistance to corrosion and further extend its service life 4.

Benefits

Using the 4892989 Studded Flange Cap Screw offers several benefits. Its design allows for improved load distribution, which reduces the risk of component failure under stress. The secure fastening provided by the screw enhances overall system reliability. Furthermore, its resistance to vibration and corrosion ensures longevity in harsh operating environments, making it a valuable component for heavy-duty truck applications 5.

Installation Guidelines

Proper installation of the 4892989 Studded Flange Cap Screw is crucial for optimal performance. Begin by ensuring the mating surfaces are clean and free of debris. Use the appropriate tools to insert the screw into the designated hole. Tighten the screw to the specified torque using a torque wrench to avoid over-tightening, which can lead to damage. It is also recommended to use a thread locker to prevent loosening due to vibration. Following these guidelines will help ensure the screw functions as intended and maintains its integrity over time 6.

Troubleshooting Common Issues

Common issues with Studded Flange Cap Screws include loosening, corrosion, and damage. If a screw appears loose, it should be re-tightened to the specified torque and a thread locker applied if not already used. Corrosion can be addressed by cleaning the affected area and applying a corrosion-resistant coating. Damaged screws should be replaced to prevent further complications. Regular inspections can help identify these issues early, allowing for timely intervention 7.

Maintenance Tips

To prolong the lifespan of the 4892989 Studded Flange Cap Screw, regular maintenance is recommended. Inspect the screws periodically for signs of wear, corrosion, or loosening. Clean the screws and surrounding areas to remove any buildup that could affect performance. If corrosion is present, apply a suitable protective coating. Replace screws that show significant wear or damage to maintain the integrity of the truck’s mechanical system 8.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the automotive industry, known for its high-quality components and engines. With a rich history of innovation and a strong reputation for reliability, Cummins is committed to producing components that meet the rigorous demands of heavy-duty applications. Their expertise in designing and manufacturing critical parts like the 4892989 Studded Flange Cap Screw ensures that truck operators can rely on their equipment for durable and efficient performance 9.

Integration of Studded Flange Cap Screw in Cummins Engines

The Studded Flange Cap Screw, part number 4892989, manufactured by Cummins, plays a crucial role in the assembly and functionality of various Cummins engines. This part is integral to ensuring the secure fastening of flanges, which are essential components in the engine’s design.

Application in Cummins Engines

ISBE CM800 Series

The ISBE CM800 engine series, known for its robust performance and reliability, utilizes the Studded Flange Cap Screw in several critical areas. These screws are employed in the assembly of exhaust systems, where they help maintain the integrity of flange connections. The studded design of the screw provides additional grip and stability, which is vital for withstanding the high pressures and temperatures encountered in the engine’s exhaust system.

Other Cummins Engines

Beyond the ISBE CM800 series, the Studded Flange Cap Screw is also a key component in various other Cummins engine models. These engines, which span a range of applications from industrial to marine, benefit from the enhanced fastening capabilities of the studded screw. The screw’s design ensures that flanges remain tightly secured, preventing leaks and maintaining the overall efficiency and safety of the engine’s operation.

Importance of the Studded Flange Cap Screw

The use of studded flange cap screws in Cummins engines is not merely a matter of convenience but a necessity for ensuring the longevity and reliability of the engine components. The studded design provides a mechanical advantage, allowing for tighter and more secure connections. This is particularly important in high-stress environments where flanges are subjected to significant forces and vibrations.

By integrating these screws into their engine designs, Cummins ensures that their products can perform reliably under demanding conditions, thereby maintaining the trust and satisfaction of their customers 10.

Role of Part 4892989 Studded Flange Cap Screw in Engine Systems

The 4892989 studded flange cap screw is integral to ensuring secure and reliable connections within various engine systems. Its design allows it to effectively fasten components together, maintaining the integrity of the system under operational conditions.

Connection

In engine systems, the 4892989 studded flange cap screw is often used to join components that require a robust and leak-proof seal. It ensures that parts remain firmly attached, preventing any unwanted movement or separation that could lead to performance issues or failures.

Air Intake

Within the air intake system, this screw plays a significant role in securing the connections between the air filter housing and the intake manifold. A secure connection here is essential to maintain the correct airflow into the engine, which is vital for optimal combustion and overall engine efficiency.

Injector Plumbing

The injector plumbing system relies on the 4892989 studded flange cap screw to maintain the integrity of fuel lines and connections. It ensures that fuel is delivered consistently and without leaks, which is important for the precise operation of fuel injectors and the overall fuel delivery system.

Plumbing

In broader plumbing applications within the engine, this screw is used to connect various hoses and pipes that carry fluids such as coolant, oil, and other essential liquids. Its ability to create a tight seal helps prevent leaks and ensures that these fluids are delivered where needed without loss.

Injector

Finally, the screw is utilized in the assembly and connection of fuel injectors to the engine block or cylinder head. This ensures that the injectors are held in place securely, allowing them to function correctly and deliver fuel in the precise amounts and timing required for efficient engine operation 11.

Conclusion

The 4892989 Studded Flange Cap Screw by Cummins is a critical component in heavy-duty truck and engine systems. Its robust design, high-strength materials, and secure fastening capabilities make it essential for maintaining the integrity and performance of various engine components. Proper installation, regular maintenance, and timely troubleshooting are key to ensuring the longevity and reliability of this part in demanding applications.

-

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ -

Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems, Owen C Duffy and Gus Wright, Jones Bartlett Learning, 2016.

↩ -

Diesel Engine System Design, Qianfan Xin, Woodhead Publishing, 2011.

↩ -

Modern Diesel Technology Electricity Electronics, Joseph A Bell, Delmar Cengage Learning, 2014.

↩ -

Cummins Inc., Service Manual (5504636), QSK78 CM2350 K137.

↩ -

Cummins Inc., Service Manual (5504636), QSK78 CM2350 K137.

↩ -

Cummins Inc., Service Manual (5504636), QSK78 CM2350 K137.

↩ -

Cummins Inc., Service Manual (5504636), QSK78 CM2350 K137.

↩ -

Cummins Inc., Service Manual (5504636), QSK78 CM2350 K137.

↩ -

Cummins Inc., Service Manual (5504636), QSK78 CM2350 K137.

↩ -

Cummins Inc., Service Manual (5504636), QSK78 CM2350 K137.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.