4980975

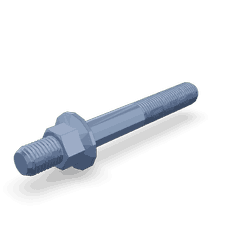

Studded Flange Cap Screw

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4980975 Studded Flange Cap Screw is a specialized fastener designed for heavy-duty truck applications. Manufactured by Cummins, a renowned name in the automotive industry, this component is integral to ensuring the secure assembly of various truck components. Its robust design and high-quality materials make it suitable for the demanding conditions encountered in heavy-duty trucking 1.

Basic Concepts of Studded Flange Cap Screws

A studded flange cap screw is a type of fastener that includes a threaded stud and a flanged head. The stud extends beyond the nut, providing additional length and strength. This design allows for secure fastening in applications where standard cap screws may not suffice. Unlike standard cap screws, which have a simple head and thread, studded flange cap screws offer enhanced stability and resistance to loosening. They are often used in applications requiring high torque and durability 2.

Role of the 4980975 Studded Flange Cap Screw in Truck Operation

The 4980975 Studded Flange Cap Screw plays a significant role in the operation of heavy-duty trucks by securing critical components and assemblies. It is commonly used in engine mounts, transmission housings, and other high-stress areas where reliable fastening is paramount. The screw’s design ensures that components remain firmly in place, even under extreme vibrations and loads, contributing to the overall safety and performance of the truck 3.

Key Features

The 4980975 Studded Flange Cap Screw boasts several key features that enhance its performance. It is made from high-strength alloy steel, providing excellent durability and resistance to wear. The threading is precision-machined to ensure a secure fit, while the flanged head distributes load more effectively than standard screws. Additionally, the screw’s design includes a studded extension that allows for greater torque application without risking damage to the fastener or the components being joined 4.

Benefits of Using the 4980975 Studded Flange Cap Screw

Using the 4980975 Studded Flange Cap Screw offers several advantages. Its high-strength material composition ensures longevity and reliability in demanding applications. The flanged head provides better load distribution, reducing the risk of component failure. The studded design allows for higher torque application, making it ideal for securing heavy and critical truck components. Additionally, the screw’s resistance to vibration and loosening ensures that assemblies remain secure over time, enhancing safety and performance 5.

Installation Guidelines

Proper installation of the 4980975 Studded Flange Cap Screw is crucial for ensuring secure and effective fastening. Begin by cleaning the mating surfaces to remove any debris or contaminants. Insert the screw through the designated hole and use a torque wrench to tighten it to the specified torque setting. It is important to follow the manufacturer’s torque specifications to avoid over-tightening, which can damage the screw or the components being joined. Additionally, ensure that the flange is seated properly against the surface to maximize load distribution 6.

Troubleshooting Common Issues

Common issues with studded flange cap screws include loosening, corrosion, and damage. If a screw appears loose, it should be re-torqued to the specified setting. Corrosion can be addressed by cleaning the affected area and applying a corrosion-resistant coating. Damaged screws should be replaced to ensure the integrity of the assembly. Regular inspections can help identify these issues early, allowing for timely maintenance and repairs 7.

Maintenance Tips

Regular maintenance of the 4980975 Studded Flange Cap Screw is essential for ensuring longevity and reliable performance. Inspect the screw and surrounding components periodically for signs of wear, corrosion, or damage. Re-torque the screw at recommended intervals to maintain secure fastening. Applying a corrosion-resistant coating can further protect the screw from environmental factors. Following these maintenance practices will help ensure the screw continues to perform effectively over time 8.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is known for its commitment to quality and innovation. The company’s extensive experience in manufacturing truck components ensures that products like the 4980975 Studded Flange Cap Screw meet the highest standards of performance and reliability. Cummins’ dedication to advancing technology and improving product quality makes it a trusted name in the industry 9.

Compatibility with Cummins Engines

The Studded Flange Cap Screw part number 4980975, manufactured by Cummins, is a critical component in the assembly and maintenance of several Cummins engine models. This part is essential for securing flanges and ensuring a tight seal in various engine applications. Below is a detailed description of its compatibility with the specified engines:

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- ISB/ISD6.7 CM2150 SN

- ISBE CM2150

- ISB6.7 G CM2180 B118

- ISBE4 CM850

- ISF3.8 CM2220 F103

- ISX12 G CM2180 EJ

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F114

These engines utilize the Studded Flange Cap Screw part 4980975 in their construction. This screw is integral for maintaining the integrity of flange connections, which are crucial for sealing and structural support in these engines 10.

Role of Part 4980975 Studded Flange Cap Screw in Engine Systems

The Part 4980975 Studded Flange Cap Screw is instrumental in securing and maintaining the integrity of various components within engine systems. Its application spans across multiple subsystems, ensuring that each part functions optimally and remains securely in place.

Cooler and Engine Oil Systems

In the cooler and engine oil systems, the Studded Flange Cap Screw is used to fasten components such as the oil filter housing and cooler modules. This ensures a tight seal, preventing leaks and maintaining the pressure integrity of the oil system. The screw’s design allows for easy installation and removal, facilitating routine maintenance and filter changes 11.

Fuel Control and Fuel Filter Location

Within the fuel control system, the Studded Flange Cap Screw plays a significant role in securing the fuel filter housing and related modules. This is essential for maintaining a consistent fuel flow and pressure, which are vital for engine performance. The screw’s studded flange provides additional stability, reducing the risk of vibrations loosening the connection over time 12.

Rear Gear and Engine Control Module

In the rear gear assembly, the Studded Flange Cap Screw is employed to secure components that are subject to significant stress and movement. This includes fastening the engine control module housing, ensuring that sensitive electronic components remain protected and securely mounted. The screw’s design helps distribute load evenly, enhancing the durability of the connection 13.

Plumbing and Exhaust Recirculation Air System

For the plumbing and exhaust recirculation air system, the Studded Flange Cap Screw is used to connect various pipes and housings. This is particularly important in maintaining the integrity of the exhaust recirculation system, where precise connections are necessary to regulate air flow and reduce emissions. The screw’s flange provides a robust connection point, capable of withstanding the high temperatures and pressures within the system 14.

Ignition System

In the ignition system, the Studded Flange Cap Screw is utilized to secure ignition modules and related components. This ensures that the ignition system remains stable and functions correctly, contributing to reliable engine start-up and operation. The screw’s design allows for secure fastening without risking damage to the sensitive ignition components 15.

Conclusion

Overall, the Part 4980975 Studded Flange Cap Screw is a versatile fastener that enhances the reliability and performance of various engine systems by providing secure, stable connections across a range of applications. Its robust design, high-strength materials, and precision machining make it an essential component in heavy-duty truck operations, ensuring the secure assembly of critical components and contributing to the overall safety and performance of the vehicle.

-

Williams, Daniel. Generalized Vehicle Dynamics. SAE International, 2022.

↩ -

Arora, Shashank, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi. Heavyduty Electric Vehicles: From Concept to Reality. Elsevier, 2021.

↩ -

Isermann, Rolf. Combustion Engine Diagnosis. Springer Vieweg, 2017.

↩ -

Cummins Inc. General Information. Bulletin Number 4021418, Troubleshooting and Repair Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021418, Troubleshooting and Repair Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021418, Troubleshooting and Repair Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021418, Troubleshooting and Repair Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021418, Troubleshooting and Repair Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021418, Troubleshooting and Repair Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021418, Troubleshooting and Repair Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021418, Troubleshooting and Repair Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021418, Troubleshooting and Repair Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021418, Troubleshooting and Repair Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021418, Troubleshooting and Repair Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021418, Troubleshooting and Repair Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.