4992199

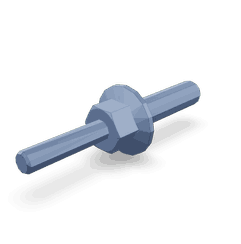

Studded Flange Cap Screw

Cummins®

AVAILABLE

7 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Studded Flange Cap Screw, identified by Part #4992199, is a component manufactured by Cummins, a well-established name in the automotive industry. This part is significant in heavy-duty truck applications due to its role in ensuring the secure attachment of various components. Cummins, known for its robust and reliable parts, provides this screw as part of its extensive product range designed to meet the demanding requirements of heavy-duty vehicles.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that includes a threaded stud and a cap screw. The stud is designed to pass through holes in flanges or other components, while the cap screw is used to secure the stud in place. This design allows for a strong and durable connection, essential for the mechanical integrity of heavy-duty trucks. The screw’s components work together to distribute load and stress evenly, ensuring stability and reliability in operation 1.

Purpose and Role in Truck Operation

The Studded Flange Cap Screw plays a role in the operation of a truck by securing flanges and other components that require a strong, permanent connection. It is commonly used in applications where vibration and dynamic loads are present, such as in the engine, transmission, and chassis components. By providing a secure attachment, the screw helps maintain the alignment and integrity of these components, contributing to the overall performance and safety of the truck 2.

Key Features

The Studded Flange Cap Screw is characterized by several key features that enhance its performance. Its design includes a threaded stud that allows for easy installation and removal, while the cap screw provides a tight and secure fit. The material composition typically includes high-strength steel, which offers excellent resistance to wear, corrosion, and fatigue. Additionally, the screw may feature a flanged head that distributes load more effectively and prevents loosening due to vibration.

Benefits

Using a Studded Flange Cap Screw offers several benefits in truck operations. Its high-strength material composition contributes to improved durability, allowing it to withstand the rigors of heavy-duty use. The secure attachment provided by the screw enhances the reliability of connected components, reducing the risk of failure. Furthermore, the efficient load distribution and resistance to loosening ensure optimal performance and longevity, contributing to the overall efficiency of truck operations.

Installation Process

Proper installation of the Studded Flange Cap Screw involves several steps to ensure a secure and lasting connection. Begin by aligning the threaded stud with the holes in the flanges or components to be connected. Insert the stud through the holes, ensuring it passes completely through. Next, place the cap screw over the stud and tighten it using the appropriate tool, taking care not to over-tighten, which could damage the threads or components. It is also important to check for proper alignment and torque specifications to avoid common pitfalls such as stripped threads or component damage.

Troubleshooting and Maintenance

Common issues with the Studded Flange Cap Screw may include loosening due to vibration or corrosion. To troubleshoot, inspect the screw and surrounding components for signs of wear, corrosion, or misalignment. If loosening is detected, re-tighten the cap screw to the recommended torque specification. Regular maintenance involves checking the screw for signs of wear or damage and ensuring that all connected components remain properly aligned. Applying a thread locker or anti-seize compound can help prevent loosening and corrosion, respectively.

Compatibility and Applications

The Studded Flange Cap Screw is typically used in a variety of applications within heavy-duty trucks, including engine, transmission, and chassis components. It is important to ensure compatibility with other components to maintain the integrity of the connection. When replacing or installing a new screw, verify that it matches the specifications and requirements of the application to ensure optimal performance and longevity.

Cummins Overview

Cummins is a leading manufacturer in the automotive industry, known for its wide range of products designed for heavy-duty applications. With a history of innovation and quality, Cummins has established a strong reputation for producing reliable and durable components. The company’s product range includes engines, powertrain components, and aftermarket parts, all of which are designed to meet the demanding requirements of heavy-duty vehicles. Cummins’ commitment to quality and performance makes it a trusted choice for professionals in the automotive industry.

Studded Flange Cap Screw 4992199 Compatibility with Cummins Engines

The Studded Flange Cap Screw part number 4992199, manufactured by Cummins, is a critical component used in various engine assemblies. This part is designed to secure flanges and other components, ensuring a tight and reliable connection. Here is a detailed overview of its compatibility with different Cummins engines:

15N CM2380 M104B, 6C8.3, B5.9 CM2670 B166C, B6.7 CM2350 B135B

The Studded Flange Cap Screw 4992199 is suitable for use in the 15N CM2380 M104B, 6C8.3, B5.9 CM2670 B166C, and B6.7 CM2350 B135B engines. These engines are part of the smaller to medium-sized engine lineup, often used in various industrial and commercial applications. The screw’s design ensures it can withstand the operational stresses and provide a secure fastening solution.

ISB5.9 CM2880 B127, ISL9 CM2150 SN, ISL9.5 CM2880 L138

For the ISB5.9 CM2880 B127, ISL9 CM2150 SN, and ISL9.5 CM2880 L138 engines, the Studded Flange Cap Screw 4992199 is an ideal choice. These engines are known for their robust performance and reliability in heavy-duty applications. The screw’s studded design provides additional grip and stability, which is crucial for maintaining the integrity of flange connections in these high-performance engines.

L8.9 CM2670 L134C, L8.9G CMOH2.0 L125B, L9 CM2670 L128B, L9.3 L105

The engines L8.9 CM2670 L134C, L8.9G CMOH2.0 L125B, L9 CM2670 L128B, and L9.3 L105 also benefit from the use of the Studded Flange Cap Screw 4992199. These engines are typically used in medium to large-scale applications, and the screw’s design ensures it can handle the specific demands of these engine configurations.

QSC8.3 CM2880 C102, QSL9.3 CM2880 L113, Z14 CM2670 Z103B

Finally, the QSC8.3 CM2880 C102, QSL9.3 CM2880 L113, and Z14 CM2670 Z103B engines are also compatible with the Studded Flange Cap Screw 4992199. These engines are often used in demanding environments, and the screw’s robust design ensures it can provide the necessary security and stability in these applications.

In summary, the Studded Flange Cap Screw 4992199 is a versatile and reliable component that is compatible with a wide range of Cummins engines, providing essential fastening for flange connections across various engine types and applications.

Role of Part 4992199 Studded Flange Cap Screw in Engine Systems

The 4992199 studded flange cap screw is integral to the assembly and functionality of various engine components. Its primary role is to secure and maintain the integrity of connections within the engine system.

Cover and Gear Cover

In the context of the engine cover and gear cover, the 4992199 screw ensures that these protective enclosures are firmly attached. This is essential for safeguarding internal components from external contaminants and ensuring that the covers remain in place during operation.

Front Gear and Manifold

When used with the front gear and manifold, the studded flange cap screw plays a key role in maintaining the alignment and structural stability of these components. Proper fastening is necessary to prevent misalignment, which could lead to inefficient operation or mechanical failure.

Air Intake and Exhaust Recirculation Air

For the air intake system and exhaust recirculation air components, the screw helps in securing connections that are vital for the smooth flow of air. This is important for maintaining optimal engine performance and efficiency.

Water Manifold and Plumbing

In water manifolds and plumbing systems, the 4992199 screw ensures that coolant pathways are securely sealed. This is essential for effective heat management within the engine, preventing leaks that could lead to overheating or system failure.

Mounting

The screw is also used in mounting various engine components. Its studded design provides additional stability and resistance to vibration, which is crucial for components that experience significant mechanical stress during engine operation.

In summary, the 4992199 studded flange cap screw is a versatile fastener that enhances the reliability and performance of multiple engine systems by ensuring secure and stable connections.

Conclusion

The Studded Flange Cap Screw, part number 4992199, manufactured by Cummins, is a critical component in heavy-duty truck applications. Its robust design and high-strength material composition ensure secure and durable connections across various engine components. Proper installation, maintenance, and understanding of its compatibility with different Cummins engines are essential for optimal performance and longevity in heavy-duty vehicle operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.