3058686

Twelve Point Cap Screw

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Part #3058686 Twelve Point Cap Screw is a specialized fastener designed for use in commercial truck maintenance. This component is integral to the assembly and maintenance of heavy-duty trucks, ensuring that critical components are securely fastened and that the structural integrity of the vehicle is maintained. Its application spans various truck assemblies, making it a vital part in the upkeep and operation of commercial vehicles 2.

Basic Concepts of Twelve Point Cap Screws

A twelve point cap screw is a type of fastener that features a twelve-sided head, as opposed to the more common six-sided head found on standard cap screws. This design allows for a greater contact area between the screw head and the driving tool, which can enhance torque application and reduce the risk of cam-out—a situation where the tool slips off the screw head during tightening or loosening. The operation of a twelve point cap screw in fastening applications is similar to that of standard cap screws, involving the threading of the screw into a pre-drilled hole to secure components together 1.

Purpose and Role in Truck Operation

The Cummins Part #3058686 Twelve Point Cap Screw plays a specific role in truck assemblies by securing critical components. It is designed to ensure that parts remain firmly in place under the demanding conditions encountered in heavy-duty truck operation. This fastener contributes to the overall structural integrity of the truck, helping to maintain the alignment and functionality of various systems and components 2.

Key Features

The Cummins Part #3058686 Twelve Point Cap Screw is characterized by several key features that enhance its performance and durability. Its twelve-sided head design provides a larger contact area for tools, facilitating more efficient torque application. The screw is made from high-quality materials, ensuring resistance to corrosion and wear. It features precise threading specifications to ensure a secure fit, and its design includes unique attributes that contribute to its overall effectiveness in heavy-duty applications 3.

Benefits

The Cummins Part #3058686 Twelve Point Cap Screw offers several benefits in fastening applications. Its design allows for improved torque application, reducing the likelihood of cam-out during installation or removal. The enhanced grip provided by the twelve-sided head helps to prevent loosening over time, even under vibration and stress. Additionally, the material composition and threading specifications contribute to the screw’s durability and resistance to corrosion, making it a reliable choice for commercial truck maintenance 1.

Installation Guidelines

Proper installation of the Cummins Part #3058686 Twelve Point Cap Screw involves several steps to ensure secure and reliable fastening. Begin by selecting the appropriate tool that matches the twelve-sided head of the screw. Use a torque wrench to apply the specified torque, ensuring that the screw is tightened to the manufacturer’s recommendations. It is important to follow best practices, such as using the correct size and type of hole for the screw, to prevent damage to the fastener or the components being secured 2.

Troubleshooting and Maintenance

Common issues that may arise with twelve point cap screws include stripping, corrosion, or loosening. To address these problems, regular inspection and maintenance are recommended. If a screw shows signs of corrosion, it should be replaced to prevent further degradation. In cases of stripping, using the correct tool and applying torque within the specified range can help avoid damage. Regular tightening checks can ensure that screws remain secure over time 1.

Manufacturer Information - Cummins

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its commitment to producing high-quality components for commercial vehicles. With a history of innovation and excellence, Cummins has built a reputation for reliability and performance. The company’s dedication to quality is evident in its range of products, including the Cummins Part #3058686 Twelve Point Cap Screw, which is designed to meet the rigorous demands of heavy-duty truck applications 2.

Compatibility with Cummins Engines

The Twelve Point Cap Screw part number 3058686 is a critical component in the assembly and maintenance of several Cummins engines. This high-strength fastener is designed to provide reliable fastening in demanding environments, ensuring the integrity of engine components during operation.

M11 MECHANICAL and N14 MECHANICAL Engines

In the M11 MECHANICAL and N14 MECHANICAL engines, the 3058686 cap screw is utilized in various applications where robust fastening is required. These engines, known for their mechanical reliability, benefit from the precise fit and durability of this screw in securing critical engine parts. The screw’s twelve-point design allows for efficient torque application, reducing the risk of rounding and ensuring a secure connection.

N14 CELECT Engine

The N14 CELECT engine also incorporates the 3058686 cap screw in its construction. This engine, which combines mechanical and electronic control systems, relies on the screw’s strength and precision to maintain the alignment and stability of its components. The cap screw’s role in the CELECT engine is crucial for ensuring the engine’s performance and longevity.

NH/NT 855 Engines

Similarly, the NH/NT 855 engines utilize the 3058686 cap screw in their assembly. These engines, known for their versatility and power, depend on the screw’s ability to withstand high stresses and maintain tight tolerances. The screw’s application in these engines is essential for the proper functioning of various engine subsystems.

The consistent use of the 3058686 cap screw across these engines highlights its importance in Cummins’ engine design and manufacturing processes. This part’s compatibility with multiple engine models underscores its versatility and the trust Cummins places in its performance and reliability 2.

Role of Part 3058686 Twelve Point Cap Screw in Engine Systems

The part 3058686 Twelve Point Cap Screw is integral to the assembly and securement of various components within engine systems. Its application ensures the stability and proper functioning of these parts, contributing to the overall efficiency and reliability of the engine.

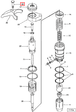

Cam Follower Housing

In the cam follower housing, the Twelve Point Cap Screw is used to fasten the housing securely to the engine block. This ensures that the cam follower operates within its designated path, maintaining the precise timing and movement essential for the engine’s performance.

Camshaft

For the camshaft, the Twelve Point Cap Screw plays a role in securing the camshaft bearings and sprockets. This securement is vital for maintaining the camshaft’s alignment and ensuring smooth operation of the valve train, which directly affects the engine’s combustion process.

Connecting Rod and Piston

Within the connecting rod and piston assembly, the Twelve Point Cap Screw is employed to fasten the connecting rod cap to the rod body. This connection is essential for withstanding the high stresses and forces generated during the engine’s operation, ensuring the piston’s reliable movement within the cylinder.

Cylinder Head

In the cylinder head, the Twelve Point Cap Screw is utilized to secure various components such as valve covers and intake manifolds. This securement is important for maintaining the integrity of the combustion chamber and ensuring a proper seal, which is critical for engine performance and efficiency.

EBM: Performance Parts

For EBM (Enhanced Performance Module) components, the Twelve Point Cap Screw is used to assemble and secure performance parts such as upgraded injectors and fuel connections. This ensures that these high-performance components are firmly in place, allowing for optimal fuel delivery and combustion.

Injector and Injector Mounting

In the context of injectors, the Twelve Point Cap Screw is crucial for mounting and plumbing the injectors. Secure fastening ensures that injectors are properly aligned and sealed, which is essential for precise fuel injection and overall engine performance.

Spacer and Fan Pilot

The Twelve Point Cap Screw also finds its application in securing spacers and fan pilots. These components require stable and precise mounting to function correctly, contributing to the engine’s cooling system and overall operational balance.

Fuel Connection

Lastly, in fuel connections, the Twelve Point Cap Screw ensures that fuel lines and fittings are securely attached. This is important for maintaining the integrity of the fuel system, preventing leaks, and ensuring consistent fuel delivery to the engine 3.

Conclusion

The Cummins Part #3058686 Twelve Point Cap Screw is a critical component in the maintenance and operation of heavy-duty trucks and Cummins engines. Its unique design, high-quality materials, and precise threading specifications make it a reliable and durable fastener for demanding applications. Proper installation and regular maintenance are essential to ensure the continued performance and reliability of this part in commercial vehicle operations.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ ↩ ↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ ↩ ↩ ↩ ↩ -

Hilgers, M. (2023). Chassis and Axles. Springer Vieweg.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.