This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

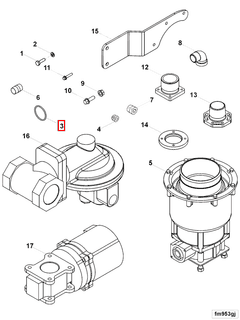

The 145538 O-Ring Seal, manufactured by Cummins, is a component used in the maintenance and operation of commercial trucks. Cummins, a well-established name in the commercial vehicle industry, produces a range of parts designed to enhance the performance and reliability of heavy-duty trucks. This Cummins part plays a role in ensuring the smooth operation of various truck systems.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket consisting of a toroidal piece of elastomer with a round cross-section designed to be seated in a groove and compressed during assembly between two or more parts, creating a seal at the interface 1. O-Ring Seals are widely used in mechanical systems to prevent the leakage of fluids and gases, and to keep out contaminants. They operate by deforming under compression, filling the space between mating surfaces and creating a seal.

Purpose of the 145538 O-Ring Seal in Truck Operation

This part is specifically designed for use in commercial trucks. It is applied in various systems where sealing is required to maintain system integrity and performance. This includes fuel systems, hydraulic systems, and engine components where it helps to prevent leaks and ensure efficient operation.

Key Features of the 145538 O-Ring Seal

This part is engineered with specific design and material characteristics to withstand the demanding conditions of heavy-duty truck applications. It is made from materials that offer durability, resistance to a range of chemicals, and the ability to operate effectively across a wide temperature range. These features make it suitable for the rigorous environments encountered in commercial trucking 2.

Benefits of Using the 145538 O-Ring Seal

Utilizing this Cummins part in truck systems can lead to improved reliability, reduced maintenance requirements, and enhanced overall performance. Its design and material properties contribute to a more dependable seal, which in turn supports the efficient operation of truck systems under various conditions.

Installation Considerations

Proper installation of this part is vital to ensure its optimal performance and longevity. Best practices include ensuring the groove is clean and free of debris before installation, using the correct amount of lubrication to facilitate seating, and avoiding over-compression which can lead to seal failure. Common pitfalls such as improper sizing or damage during installation should be avoided.

Troubleshooting Common Issues

O-Ring Seals in commercial trucks may encounter issues such as leaks or failure due to wear, incorrect installation, or environmental factors. Troubleshooting these problems involves a systematic approach to identify the root cause, which may include inspecting the seal and groove for damage, checking for proper installation, and assessing environmental conditions that may affect seal performance.

Maintenance Tips

Regular maintenance of the 145538 O-Ring Seal is recommended to ensure continued system reliability. This includes periodic inspections for signs of wear or damage, adhering to recommended replacement intervals, and following proper procedures for removal and installation to prevent damage to the seal or groove.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial vehicle industry. The company’s product range is designed to meet the demanding requirements of heavy-duty applications, ensuring reliability and performance in various operating conditions 3.

Compatibility of 145538 with Cummins Engines

This part is compatible with a range of Cummins engines, including the G5.9 CM558, G8.3 CM558, G855 CM558, GTA8.3 CM558, QSL9 G CM558, and V28 engines. It is engineered to fit seamlessly within these engines, providing essential sealing capabilities that are vital for maintaining engine integrity and performance.

Role of 145538 in Engine Systems

This part is integral to maintaining the integrity and efficiency of various engine systems. Its application spans across multiple components, ensuring that each system operates within optimal parameters.

Connection Points

At connection points, 145538 ensures a tight and leak-free seal between mating surfaces. This is particularly important in systems where fluid dynamics play a significant role, such as in the Air Intake system. Here, the seal prevents any air leaks that could compromise engine performance.

Air Intake System

In the Air Intake system, 145538 is used to secure connections between the intake manifold and other components. This ensures that the air entering the engine is clean and metered accurately, contributing to efficient combustion.

Cooler Lubricating Filter and Filter Cooler Assemblies

Within the Cooler Lubricating Filter and Filter Cooler Assemblies, 145538 plays a vital role in maintaining the pressure integrity of the system. It ensures that the cooling fluid circulates without any leaks, which is essential for the longevity and performance of the lubricating oil.

Lube Oil Filter and Cooler

In the Lube Oil Filter and Cooler, 145538 is employed to secure the connections between the filter housing and the cooler. This ensures that the oil filtration process is efficient and that the oil remains clean, which is critical for reducing wear on engine components.

Module and Fuel Control Systems

Within Modules and Fuel Control Systems, 145538 is used to ensure that fuel lines and connections remain sealed. This is important for maintaining the correct fuel pressure and preventing any fuel leaks, which could be hazardous.

Overhaul Gasket Set and Overhaul Kit

In Overhaul Gasket Sets and Overhaul Kits, 145538 is often included to replace worn-out seals during engine maintenance. This ensures that the engine can be reassembled with confidence, knowing that all seals are intact and functional.

Upper Engine Gasket Kit and Upper Engine Gasket Set

The Upper Engine Gasket Kit and Upper Engine Gasket Set utilize 145538 to ensure that the upper components of the engine, such as the Rocker Arm Housing, are sealed properly. This prevents any oil or coolant leaks that could affect engine performance.

PDC and Lever Systems

In PDC (Powertrain Control Module) and Lever Systems, 145538 is used to ensure that any fluid-operated components function without leaks. This is particularly important in systems where precise control and operation are required.

Rocker and Base Components

For Rocker and Base Components, 145538 ensures that any lubrication points are sealed effectively. This is important for reducing friction and wear on these moving parts.

Parts and Kits

In various Parts and Kits, 145538 is a common component used to ensure that all connections within the kit are sealed properly. This is essential for the kit to function as intended upon installation.

Conclusion

The application of 145538 across these components demonstrates its versatility and importance in maintaining the efficiency and reliability of engine systems. Proper installation, maintenance, and understanding of its role in various systems are crucial for maximizing the benefits of this Cummins part in commercial truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.