This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 145589 O-Ring Seal is a component designed for use in commercial trucks. It serves to ensure the integrity of seals within various systems of the vehicle. Manufactured by Cummins, a well-established name in the automotive industry, this O-Ring Seal is crafted to meet the demanding requirements of heavy-duty applications 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a circular ring made from elastomer materials, designed to create a seal between two or more parts. It functions by being compressed within a groove, creating a barrier that prevents the leakage of fluids or gases. O-Ring Seals are widely used in mechanical systems for their simplicity, effectiveness, and versatility in sealing applications 2.

Role of the 145589 O-Ring Seal in Truck Operation

This Cummins part plays a specific role in the operation of commercial trucks by ensuring the seal integrity in various systems or components. It is typically associated with fluid systems where maintaining pressure and preventing leaks is necessary for optimal performance. This includes applications in fuel systems, hydraulic systems, and other areas where fluid dynamics are critical.

Key Features

This Cummins part is characterized by several key features that enhance its performance. These include its material composition, which is designed to withstand the harsh conditions encountered in commercial truck operations. The seal is also engineered for durability, ensuring long-term reliability even under stress. Its design specifications are tailored to provide an effective seal in the specific applications it is intended for.

Benefits of Using the 145589 O-Ring Seal

Incorporating this Cummins part into truck maintenance and operation offers several advantages. These include improved efficiency in sealing applications, enhanced reliability due to its robust construction, and increased longevity, reducing the need for frequent replacements. The seal contributes to the overall performance and durability of the truck’s systems.

Installation and Maintenance

Proper installation of this Cummins part is crucial for its effective function. Guidelines for installation include ensuring the groove is clean and free of debris before placing the seal. Maintenance practices involve regular inspection for signs of wear or damage and replacing the seal as necessary to maintain optimal performance. Following these guidelines helps ensure the seal continues to provide effective sealing over time.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals include leaks due to wear, improper installation, or exposure to incompatible fluids. Diagnostic methods involve inspecting the seal for physical damage and ensuring it is correctly seated in its groove. Solutions may include replacing the seal, cleaning the groove, or addressing any underlying issues that may have contributed to the seal’s failure.

Manufacturer - Cummins

Cummins is a reputable manufacturer in the automotive industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance components, Cummins has established itself as a leader in the field. Its products, including the 145589 O-Ring Seal, are designed with a focus on durability, efficiency, and compatibility with a wide range of applications.

Cummins O-Ring Seal 145589 Compatibility with Engine Models

145589, manufactured by Cummins, is designed to fit seamlessly within several of their engine models. This part is crucial for ensuring that various engine components maintain their integrity and operate efficiently by preventing leaks and maintaining pressure.

QSK60G Engine

In the QSK60G engine, 145589 plays a vital role in sealing critical areas. It is often used in conjunction with high-pressure systems, ensuring that the engine’s performance is not compromised by any form of leakage. This seal is integral to the engine’s overall functionality, providing a reliable barrier against oil, coolant, and other fluids.

QST30 CM552 Engine

Similarly, in the QST30 CM552 engine, 145589 is essential for maintaining the engine’s operational efficiency. This engine model, known for its robust performance, relies on precise sealing to function correctly. The O-Ring Seal ensures that the engine’s internal components are protected from contaminants and that the system’s pressure is maintained.

Grouping of Engines

Both the QSK60G and QST30 CM552 engines benefit from the use of 145589. These engines, while distinct in their applications and specifications, share a commonality in their requirement for high-quality sealing solutions. 145589 is engineered to meet the stringent demands of these engines, providing a reliable and durable solution for sealing purposes.

By ensuring that these engines have the appropriate sealing components, 145589 contributes to the longevity and reliability of the engines, making it a critical part in the maintenance and operation of the QSK60G and QST30 CM552 models.

Role of Part 145589 O-Ring Seal in Engine Systems

145589 is instrumental in maintaining the integrity and efficiency of various engine systems. Its application spans across several components, ensuring optimal performance and longevity.

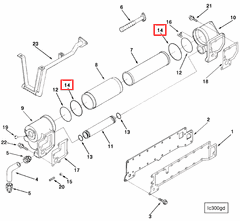

Aftercooler

In the aftercooler system, the O-Ring Seal is utilized to create a tight seal between the cooler body and its connecting components. This ensures that the compressed air is effectively cooled before entering the engine, enhancing overall engine efficiency and reducing the risk of overheating.

Kit

When included in a kit, the O-Ring Seal plays a pivotal role in ensuring that all components within the kit are securely sealed. This is particularly important in maintenance kits where the seal prevents leaks and ensures that the system operates within specified parameters.

PDC (Powertrain Control Module)

Although the PDC itself does not directly use O-Ring Seals, the seals are essential in the systems that the PDC monitors and controls. Proper sealing ensures that the data the PDC receives is accurate, allowing for precise control of engine functions.

Lower Engine Gasket Set

Within the lower engine gasket set, the O-Ring Seal is used to ensure that there are no gaps between mating surfaces. This is vital for maintaining compression and preventing oil or coolant leaks, which can lead to engine damage.

Oil Pan

The O-Ring Seal is often employed in the oil pan to ensure a secure fit between the pan and the engine block. This prevents oil leaks, which are not only messy but can also lead to a loss of lubrication and subsequent engine wear.

System

In broader engine systems, the O-Ring Seal is used in various joints and connections to maintain system integrity. Whether it’s in the fuel system, cooling system, or lubrication system, the seal ensures that fluids remain contained and pressures are maintained.

Auxiliary Cooling

For auxiliary cooling systems, the O-Ring Seal is used to ensure that coolant flows efficiently without leaks. This is essential for maintaining optimal engine temperature, especially under high-load conditions.

Water Inlet Connection

At the water inlet connection, the O-Ring Seal ensures that coolant enters the engine without any leaks. This is crucial for maintaining consistent coolant flow and engine temperature.

Water Pump Kit

In a water pump kit, the O-Ring Seal is used to ensure that the pump housing is securely sealed. This prevents coolant leaks and ensures that the pump can operate efficiently, providing consistent coolant circulation.

Water Pump Mounting

Finally, in the water pump mounting system, the O-Ring Seal is used to ensure that the pump is securely attached to the engine block. This not only prevents leaks but also ensures that the pump remains in the correct position, allowing for efficient operation.

Conclusion

The Cummins 145589 O-Ring Seal is a vital component in the maintenance and operation of commercial trucks and various engine systems. Its role in ensuring seal integrity, preventing leaks, and maintaining system pressure is critical for the efficient and reliable performance of these vehicles and engines. Proper installation, maintenance, and understanding of its applications are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.