This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 148291 O-Ring Seal is a critical component designed to maintain the integrity of fluid systems in commercial trucks. It ensures reliable sealing in various applications, contributing to the efficient operation of the vehicle. The importance of this part lies in its ability to prevent leaks and maintain system pressure, which is essential for the performance and safety of commercial trucks.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a toroidal (donut-shaped) elastomer ring used to create a seal between two or more parts. It functions by deforming under compression to fill the gap between mating surfaces, thereby preventing the escape of fluids or gases. O-Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications, including hydraulic, pneumatic, and fuel systems 1.

Purpose of the Cummins 148291 O-Ring Seal

This Cummins part plays a specific role in the operation of commercial trucks by ensuring the sealing of fluid passages within the engine and other systems. It is typically placed in grooves or around components where fluid transfer occurs. Its function is to maintain the integrity of the system by preventing leaks, which could lead to loss of efficiency or potential safety hazards 2.

Key Features

The Cummins 148291 O-Ring Seal is characterized by several key features that make it suitable for heavy-duty applications. It is composed of durable elastomer materials that can withstand high temperatures, pressures, and a range of chemical exposures. The design specifications of this O-Ring Seal ensure a precise fit and optimal sealing performance, contributing to its longevity and reliability in demanding environments 3.

Benefits

Utilizing the Cummins 148291 O-Ring Seal offers several benefits. It provides improved sealing efficiency, which helps in maintaining system pressure and preventing fluid leaks. The durability of the material ensures a longer service life, reducing the frequency of replacements. Additionally, its resistance to various environmental factors, such as temperature fluctuations and chemical exposure, enhances the overall reliability of the sealing solution 4.

Installation Process

Proper installation of the Cummins 148291 O-Ring Seal is crucial for ensuring its effectiveness. The process involves cleaning the groove where the O-Ring will be placed to remove any debris or old sealant. The O-Ring should be lubricated with a compatible fluid to facilitate insertion and prevent damage. It is important to ensure that the O-Ring is not twisted or kinked during installation, as this could compromise its sealing ability.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals include leaks, which can be caused by improper installation, damage to the O-Ring, or degradation of the material over time. Diagnosing these issues involves inspecting the O-Ring for signs of wear, checking the groove for debris or damage, and ensuring that the system is operating within the specified parameters for temperature and pressure. Addressing these issues may require replacing the O-Ring or repairing the groove.

Maintenance Tips

Regular maintenance of the Cummins 148291 O-Ring Seal is important for ensuring optimal performance and longevity. This includes periodic inspection for signs of wear or damage, cleaning the groove to prevent contamination, and replacing the O-Ring according to the manufacturer’s guidelines or when signs of degradation are observed. Adhering to these maintenance practices helps in preventing unexpected failures and ensuring the continued efficiency of the sealing system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industries. The company’s focus on research and development ensures that its products, including the Cummins 148291 O-Ring Seal, meet the high standards required for reliable performance in commercial applications.

Role of Part 148291 O-Ring Seal in Engine Systems

In the intricate assembly of engine systems, the part 148291 O-Ring Seal serves as a vital component, ensuring the integrity and efficiency of various engine parts.

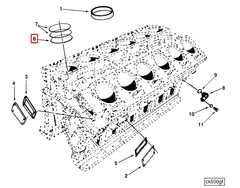

Integration with the Cylinder Block

The cylinder block, a fundamental part of the engine, houses the cylinders where combustion occurs. The O-Ring Seal, when installed in conjunction with the cylinder block, plays a significant role in preventing leaks. It ensures that the fluids and gases remain contained within the designated pathways, maintaining the pressure and efficiency of the combustion process. This seal is typically placed in grooves or around ports where external components connect to the cylinder block, such as fuel injectors or coolant passages.

Functionality within the Gasket Set

A gasket set is a collection of gaskets used to seal the various mating surfaces in an engine, preventing the escape of fluids and gases. The O-Ring Seal complements the gasket set by providing a dynamic seal in areas where static gaskets cannot suffice, such as around moving parts or in areas subject to vibration. It is often used in conjunction with head gaskets, intake manifold gaskets, and oil pan gaskets to enhance the sealing capabilities and ensure a robust barrier against leaks.

Conclusion

By understanding the specific applications and benefits of the part 148291 O-Ring Seal within these components, engineers and mechanics can better appreciate its contribution to the overall performance and reliability of engine systems.

-

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Naunheimer, Harald, et al. Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg, 2011.

↩ -

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.