153994

Rectangular Ring Seal

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 153994 Rectangular Ring Seal, manufactured by Cummins, is a critical component designed to enhance the operation of commercial trucks. This seal is essential for maintaining the integrity of various systems within these vehicles, meeting the demanding requirements of heavy-duty applications 1.

Basic Concepts of Rectangular Ring Seals

A Rectangular Ring Seal is a type of gasket designed to create a tight seal between two surfaces. It functions by filling the gap between mating surfaces, preventing the leakage of fluids or gases. These seals are commonly used in mechanical systems where reliable sealing is required under varying conditions. Materials used in the construction of Rectangular Ring Seals typically include rubber, silicone, and various types of synthetic compounds, chosen for their durability and resistance to environmental factors 2.

Purpose of the 153994 Rectangular Ring Seal in Truck Operation

The 153994 Rectangular Ring Seal is integral to the operation of commercial trucks, particularly in systems where fluid or gas containment is necessary. It is often associated with engine components, transmission systems, and hydraulic systems. By providing a reliable seal, it helps maintain system efficiency and prevent leaks that could lead to performance issues or safety hazards.

Key Features of the 153994 Rectangular Ring Seal

The 153994 Rectangular Ring Seal is characterized by its rectangular cross-section, which allows it to conform to irregular surfaces and provide a consistent seal. The seal is made from materials that offer excellent resistance to wear, temperature extremes, and chemical exposure. Its design ensures that it can withstand the high pressures and dynamic conditions typical in commercial truck applications 3.

Benefits of Using the 153994 Rectangular Ring Seal

Utilizing the 153994 Rectangular Ring Seal offers several advantages. It provides improved sealing efficiency, ensuring that systems operate without leaks. Its durability allows it to maintain performance over extended periods, even under harsh operating conditions. Additionally, its resistance to various environmental factors enhances the reliability of the systems it is part of.

Installation Considerations

Proper installation of the 153994 Rectangular Ring Seal is vital for ensuring optimal performance and longevity. Guidelines recommend that the mating surfaces be clean and free of debris to allow the seal to form a proper fit. Careful handling of the seal during installation helps prevent damage that could compromise its effectiveness.

Troubleshooting Common Issues

Common issues with Rectangular Ring Seals include leaks and seal failure. These problems can often be traced to improper installation, surface contamination, or exposure to conditions beyond the seal’s designed tolerances. Diagnosing these issues involves inspecting the seal and mating surfaces for damage or misalignment and addressing any identified problems to restore system integrity.

Maintenance Tips

Regular maintenance of the 153994 Rectangular Ring Seal can prolong its service life and maintain its effectiveness. This includes periodic inspection for signs of wear or damage, ensuring that mating surfaces remain clean, and replacing the seal as necessary to prevent leaks and maintain system performance.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer in the commercial truck industry, known for its wide range of products and commitment to quality. With a history of innovation and excellence, Cummins has established a strong reputation for producing reliable and high-performance components, including the 153994 Rectangular Ring Seal. Their product range encompasses engines, powertrain components, and aftermarket parts, catering to the diverse needs of the commercial trucking sector.

Role of Part 153994 Rectangular Ring Seal in Engine Systems

In the context of engine systems, the Rectangular Ring Seal (Part 153994) is integral to ensuring the efficiency and reliability of various components.

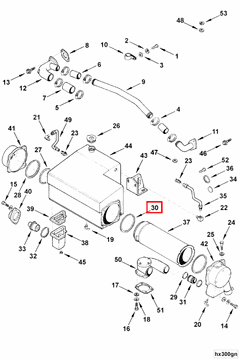

Heat Exchanger

The Rectangular Ring Seal is utilized in the heat exchanger to maintain a secure seal between the components. This seal is essential for preventing leaks and ensuring that the transfer of heat between the engine’s coolant and the ambient air is efficient. Proper sealing helps in maintaining the optimal temperature of the engine, which is vital for performance and longevity.

Kit

When included in a kit, the Rectangular Ring Seal serves as a key component to ensure that all parts within the kit function cohesively. It provides the necessary sealing properties required for the assembly of various engine components, ensuring that there are no gaps or leaks that could compromise the system’s integrity.

PDC (Powertrain Control Module)

Although the PDC itself does not directly interact with the Rectangular Ring Seal, the seal plays a supporting role in maintaining the overall health of the engine. By ensuring that all fluid systems are sealed properly, the Rectangular Ring Seal helps in maintaining consistent engine performance, which is monitored and adjusted by the PDC.

Lower Engine Gasket Set

In the lower engine gasket set, the Rectangular Ring Seal is often used to provide additional sealing where standard gaskets may not suffice. This is particularly important in areas where high pressure or temperature variations occur. The seal helps in preventing oil or coolant leaks, which can lead to engine damage if not addressed promptly.

By integrating the Rectangular Ring Seal into these engine systems, engineers and mechanics can ensure that each component operates within its designed parameters, leading to enhanced engine performance and durability.

Conclusion

The 153994 Rectangular Ring Seal plays a vital role in the operation and maintenance of commercial trucks. Its design and materials ensure durability and reliability under harsh conditions, contributing to the overall efficiency and safety of the vehicle. Proper installation, maintenance, and understanding of its role in various engine systems are crucial for maximizing its benefits and ensuring the longevity of the truck’s components.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.