160196

Rectangular Ring Seal

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

Minimum Quantity 2

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 160196 Rectangular Ring Seal, manufactured by Cummins, is a specialized component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of high-quality parts that contribute to the efficiency and reliability of truck systems. This part is significant in maintaining the integrity of various mechanical systems within commercial trucks.

Basic Concepts of Rectangular Ring Seals

A Rectangular Ring Seal is a type of gasket used in mechanical systems to create a seal between two or more parts. It functions by filling the gap between mating surfaces, preventing the leakage of fluids or gases. These seals are commonly used in applications where a reliable seal is required under varying conditions, including temperature and pressure fluctuations. Their design allows them to conform to irregularities in surface finishes, ensuring a tight seal 1.

Purpose of the 160196 Rectangular Ring Seal in Truck Operations

This part plays a role in the operation of commercial trucks by ensuring the integrity of seals in various systems. It is specifically designed to withstand the demanding conditions found in truck environments, such as high temperatures, pressure variations, and exposure to chemicals. Its applications include sealing connections in fuel systems, hydraulic systems, and other critical areas where fluid or gas containment is necessary 2.

Key Features of the 160196 Rectangular Ring Seal

The 160196 Rectangular Ring Seal is characterized by its material composition, typically a durable elastomer or composite material that offers resistance to wear and environmental factors. Its design includes precise dimensions that ensure a snug fit in the application area, enhancing sealing efficiency. Additionally, the seal may possess unique properties such as resistance to specific chemicals or the ability to operate within a wide temperature range, further contributing to its performance in truck systems.

Benefits of Using the 160196 Rectangular Ring Seal

Utilizing this Cummins part provides several advantages in truck operations. It offers improved sealing efficiency, reducing the risk of leaks that could lead to system failures or inefficiencies. The seal’s durability ensures long-term performance, even under the harsh conditions typical of commercial truck use. Its reliability contributes to the overall safety and efficiency of truck operations, minimizing downtime and maintenance costs 3.

Installation and Maintenance Guidelines

Proper installation of the 160196 Rectangular Ring Seal is vital to ensure optimal performance. It should be installed in a clean, dry environment to prevent contamination that could compromise the seal. Careful handling is required to avoid damaging the seal during installation. Regular maintenance, including inspection for wear or damage, is recommended to prolong the seal’s lifespan and ensure continued effectiveness. Replacement should be considered if any signs of degradation are observed.

Troubleshooting Common Issues

Common issues with Rectangular Ring Seals in truck applications may include leaks, seal deformation, or failure to create a proper seal. These problems can often be traced back to incorrect installation, environmental factors, or wear and tear. Troubleshooting steps may involve re-evaluating the installation process, ensuring the mating surfaces are clean and undamaged, and replacing the seal if necessary. Regular inspections can help identify potential issues before they lead to system failures.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s commitment to excellence and customer satisfaction makes it a trusted source for high-quality truck components, including the 160196 Rectangular Ring Seal.

Rectangular Ring Seal (Part 160196) Compatibility with Cummins Engines

The Rectangular Ring Seal, identified by the part number 160196, is a crucial component in ensuring the operational integrity of various Cummins engines. This seal is designed to fit seamlessly with a range of Cummins engine models, providing a reliable barrier against leaks and maintaining system pressure.

K Series Engines

The Rectangular Ring Seal is compatible with the K19, K38, and K50 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The seal ensures that the engine’s internal components remain protected from contaminants and wear, contributing to the longevity and efficiency of the engine.

L Series Engines

For the L10 MECHANICAL engine, the Rectangular Ring Seal is an essential part of the engine’s sealing system. This engine is designed for durability and efficiency, and the seal plays a critical role in maintaining the engine’s performance by preventing oil and fluid leaks.

M Series Engines

The M11 CELECT PLUS and M11 MECHANICAL engines also benefit from the use of the Rectangular Ring Seal. These engines are equipped with advanced technology for improved performance and fuel efficiency. The seal ensures that the engine’s internal pressure is maintained, which is crucial for the proper functioning of the engine’s components.

N Series Engines

Lastly, the N14 MECHANICAL engine utilizes the Rectangular Ring Seal to maintain its operational integrity. This engine is known for its power and reliability, and the seal is a key component in ensuring that the engine operates smoothly and efficiently.

In summary, the Rectangular Ring Seal (Part 160196) is a versatile and essential component that fits seamlessly with a variety of Cummins engines, ensuring their performance and longevity.

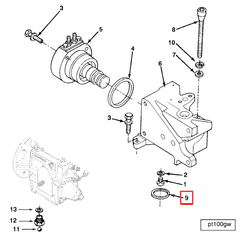

Role of Part 160196 Rectangular Ring Seal in Engine Systems

The Part 160196 Rectangular Ring Seal is an essential component that ensures the integrity and efficiency of various engine systems. Its application spans across multiple assemblies and kits, contributing to the overall performance and reliability of the engine.

Integration with Engine Installation and Spares

In the Engine Installation Kit and Engine Spares, the Rectangular Ring Seal is utilized to create a secure seal between mating surfaces. This is particularly important in preventing leaks and ensuring that all components are properly aligned during installation. The seal’s robust design helps maintain the structural integrity of the engine, facilitating a smoother installation process.

Fuel System Applications

Within the Fuel Base Pump and Fuel Top Level Assembly Pump, the Rectangular Ring Seal plays a significant role in maintaining the pressure and flow of fuel. By sealing the connections between the pump components, it ensures that fuel is delivered consistently and efficiently to the engine. This is vital for the proper functioning of the fuel injection system, where precise fuel delivery is necessary for optimal engine performance.

Gasket Sets and Hardware Kits

The Lower Engine Gasket Set and Upper Engine Gasket Set often incorporate the Rectangular Ring Seal to enhance the sealing capabilities between the engine block and other components. Similarly, in the Hardware Kit and On Board Spares Kit, these seals are used to ensure that all bolted connections remain tight and leak-free. This is especially important in high-stress areas where vibrations and thermal expansion can compromise seals over time.

Cooling and Manifold Systems

In the Engine Cooling System, the Rectangular Ring Seal is employed in the Manifold Water and Water Manifold Kit to prevent coolant leaks. Effective sealing in these areas is essential for maintaining the engine’s operating temperature and preventing overheating.

Pressure-Time Pacer Assemblies

The Pressure-Time Pacer Conversion Kit, Pressure-Time Pacer Mounting Kit, and Pressure-Time Pacer Mounting Module also benefit from the use of the Rectangular Ring Seal. These components require precise sealing to function correctly, ensuring that the pacing mechanisms operate within specified parameters. The seal helps in maintaining the integrity of the pressurized systems, which is crucial for the accurate timing and delivery of fuel and other fluids.

Overhaul and Spare Parts

During engine overhauls, the Overhaul Gasket Set and Spare Parts Kit often include the Rectangular Ring Seal to replace worn-out seals. This ensures that the engine can be restored to its original performance standards, with all connections sealed properly to prevent leaks and maintain efficiency.

In summary, the Part 160196 Rectangular Ring Seal is a versatile component that enhances the functionality and reliability of various engine systems. Its application across different kits and assemblies underscores its importance in maintaining the overall performance and longevity of the engine.

Conclusion

The 160196 Rectangular Ring Seal is a critical component in the maintenance and operation of commercial truck engines. Its role in ensuring the integrity of seals across various systems highlights its importance in the efficiency and reliability of truck operations. Proper installation, maintenance, and understanding of its applications are essential for maximizing the benefits of this Cummins part.

-

Andrew Brown Jr, Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, National Academy of Sciences, 2010.

↩ -

Dominique Bonneau, Aurelian Fatu, and Dominique Souchet, Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings, Wiley-ISTE, 2014.

↩ -

Amir Khajepour, Synthesis Lectures on Advances in Automotive Technology, Springer, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.