This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

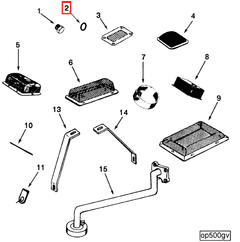

Introduction

The Cummins 185705 Rectangular Ring Seal is a critical component designed to maintain the integrity of fluid systems in commercial trucks. Its primary function is to provide a reliable seal in various applications, contributing to the efficient operation of the vehicle. Understanding its role and significance is essential for maintaining the performance and reliability of truck systems.

Basic Concepts of Rectangular Ring Seals

A Rectangular Ring Seal is a type of gasket designed to create a seal between two or more parts. It functions by filling the gap between mating surfaces, preventing the leakage of fluids or gases. These seals are commonly used in mechanical systems where a tight seal is required to maintain system efficiency and prevent contamination 1.

Purpose of the 185705 Rectangular Ring Seal

This Cummins part ensures that fluid systems remain sealed, which is crucial for maintaining system integrity, preventing leaks, and ensuring that fluids are directed correctly within the system. Its applications include use in fuel systems, hydraulic systems, and other areas where a reliable seal is necessary 2.

Key Features

The 185705 Rectangular Ring Seal is characterized by its material composition, designed to withstand the pressures and temperatures encountered in truck systems. Its design includes features that enhance its sealing capabilities, such as a rectangular cross-section that allows for a better fit in the sealing groove. Additionally, it may have unique attributes that improve its performance in specific applications 3.

Benefits

This part offers benefits such as improved sealing efficiency, which helps in maintaining system pressure and preventing leaks. Its durability ensures long-term performance, even under challenging operating conditions. The seal’s resistance to various fluids and temperatures further enhances its reliability in commercial truck applications.

Installation Process

Proper installation of the 185705 Rectangular Ring Seal involves ensuring that the sealing surfaces are clean and free of debris. The seal should be placed in the groove with care to avoid damage. Tools such as seal installation tools may be used to ensure that the seal is correctly fitted without distortion. Following the manufacturer’s guidelines for installation is crucial to ensure the seal functions as intended.

Troubleshooting Common Issues

Common problems with Rectangular Ring Seals may include leaks or seal failure. Troubleshooting these issues involves inspecting the seal and the mating surfaces for damage or wear. Ensuring that the seal is correctly installed and that the system is free of contaminants can help address these problems. In some cases, replacing the seal may be necessary to restore system integrity.

Maintenance Tips

Regular maintenance of the 185705 Rectangular Ring Seal includes inspecting the seal for signs of wear or damage. It is important to follow the manufacturer’s recommendations for inspection intervals and replacement guidelines. Keeping the sealing surfaces clean and ensuring that the system operates within specified parameters can help extend the life of the seal and maintain optimal performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s commitment to customer satisfaction and technological advancement has made it a preferred choice for truck manufacturers and operators worldwide.

Role of Part 185705 Rectangular Ring Seal in Engine Systems

This part is an essential component in various engine systems, ensuring the integrity and efficiency of these systems.

Integration with Kit Spares

In the context of kit spares, the Rectangular Ring Seal is often included to provide a reliable sealing solution for components that may experience wear and tear over time. This ensures that when replacements or repairs are needed, the seal maintains its effectiveness, preventing leaks and maintaining system pressure.

Functionality in the Kit

Within a comprehensive kit, the Rectangular Ring Seal plays a significant role in maintaining the seal between mating surfaces. This is particularly important in kits designed for engine maintenance, where the seal prevents fluid or gas leakage, ensuring the engine operates within specified parameters.

Application in PDC Systems

For Powertrain Control Modules (PDC), the Rectangular Ring Seal is used to ensure that electrical connections remain secure and free from contaminants. This is vital for the reliable operation of the PDC, as any ingress of moisture or debris can lead to malfunctions or failures.

Role in Lower Engine Gasket Kit

In a lower engine gasket kit, the Rectangular Ring Seal is employed to create a tight seal between various engine components, such as the cylinder head and engine block. This seal is essential for maintaining compression within the combustion chambers, directly impacting engine performance and efficiency.

Use in Lubricating Cooler Water Tubes

For lubricating cooler water tubes, the Rectangular Ring Seal ensures that the cooling system remains pressurized and free from leaks. This is important for maintaining the optimal temperature of the lubricant, which in turn protects various engine components from overheating and wear.

Conclusion

The Cummins 185705 Rectangular Ring Seal is a vital component in maintaining the integrity and efficiency of fluid systems in commercial trucks. Its reliable sealing capabilities, durability, and resistance to various fluids and temperatures make it an essential part for ensuring the optimal performance of truck systems. Proper installation, regular maintenance, and timely replacement are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.