193949

Grommet Seal

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 193949 Grommet Seal, manufactured by Cummins, is a critical component used in commercial trucks. This article provides an overview of the Grommet Seal, its purpose, key features, benefits, and maintenance suggestions.

Understanding Grommet Seals

A grommet seal is a type of gasket designed to provide a seal between two or more parts. It is typically made from rubber or silicone and is used to prevent fluid leaks, protect cables and wires, and reduce vibration and noise. Grommet seals are commonly found in automotive, aerospace, and industrial applications 1.

Purpose of the 193949 Grommet Seal

The 193949 Grommet Seal plays a crucial role in the truck’s system by providing a secure and leak-proof seal in various applications. It is designed to fit into specific openings or passages within the truck’s components, ensuring that fluids, such as oil or coolant, do not escape and that contaminants are kept out 2.

Key Features

This Cummins part features a durable construction, typically made from high-quality rubber or silicone. It is designed to withstand high temperatures, pressure, and chemical exposure. The seal is precision-engineered to fit snugly into its designated location, providing a reliable barrier against leaks and contaminants 3.

Benefits

The use of the 193949 Grommet Seal offers several benefits, including improved system efficiency by preventing fluid leaks, enhanced durability due to its robust construction, and reduced maintenance costs by minimizing the need for frequent repairs or replacements.

Troubleshooting and Maintenance

Regular inspection of the 193949 Grommet Seal is recommended to ensure its continued effectiveness. Signs of wear, such as cracks or deformation, should be addressed promptly. Maintenance may involve cleaning the seal and its surrounding area to remove any buildup or contaminants that could affect its performance. In some cases, replacement may be necessary to maintain system integrity.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a commitment to innovation and customer satisfaction, Cummins provides reliable and efficient solutions for various industries, including transportation, construction, and agriculture.

Role of Part 193949 Grommet Seal in Engine Systems

Part 193949 Grommet Seal is an essential component that ensures the integrity and efficiency of various engine systems. Its primary function is to provide a secure and leak-proof seal between different engine components, thereby maintaining optimal performance and longevity of the engine.

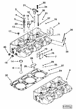

Integration with Cylinder Head and Gaskets

In the context of the cylinder head and associated gaskets, the Grommet Seal plays a significant role in sealing the passages where wires, hoses, or other components pass through the cylinder head. This seal prevents coolant, oil, or other fluids from leaking out, which could lead to engine damage or reduced efficiency. When paired with a cylinder head gasket or a single head gasket set, the Grommet Seal ensures that the combustion chamber remains sealed, maintaining compression and preventing fluid contamination.

Contribution to Engine Gasket Sets

Within an engine gasket set or an upper engine gasket kit, the Grommet Seal is often used to seal specific points where external components interface with the engine block or head. This is particularly important in maintaining the integrity of the engine’s cooling and lubrication systems. The Grommet Seal works in conjunction with other gaskets to create a comprehensive sealing solution that protects the engine from leaks and contaminants.

Role in Cylinder Long Block and Overhaul Kits

In a cylinder long block or an overhaul kit, the Grommet Seal is vital for ensuring that all fluid pathways are securely sealed. This is especially important during engine rebuilds or overhauls, where every component must be meticulously sealed to prevent leaks that could compromise the engine’s performance. The Grommet Seal, when used in conjunction with an overhaul gasket set, helps to guarantee that the engine operates efficiently post-overhaul.

Application in Performance Parts and Spares

For performance parts and engine spares, the Grommet Seal is often included in kits such as the kit spares or engine spares kit. Its role here is to enhance the sealing capabilities of high-performance engines, where even the smallest leak can significantly impact performance. By ensuring a tight seal, the Grommet Seal contributes to the overall reliability and efficiency of performance-oriented engine builds.

Usage in Lower and Upper Engine Gasket Sets

In both lower and upper engine gasket sets, the Grommet Seal is employed to seal critical points where fluids or wires pass through the engine block or head. This is particularly important in maintaining the separation between different fluid systems within the engine, such as the cooling and lubrication systems. The Grommet Seal, when used in these sets, helps to prevent cross-contamination and ensures that each system operates within its designed parameters.

Summary of Component Interactions

The Grommet Seal interacts with a variety of engine components, including the cylinder head, cylinder head gasket, engine gasket set, and various kits such as the overhaul kit and performance parts. Its role in sealing fluid pathways and preventing leaks is indispensable for maintaining the engine’s efficiency, reliability, and longevity. Whether used in routine maintenance, overhauls, or high-performance builds, the Grommet Seal is a key component in ensuring the engine operates at its best.

Conclusion

The 193949 Grommet Seal is a vital component in commercial trucks, ensuring the integrity and efficiency of engine systems. Its durable construction, precision engineering, and role in preventing leaks and contaminants make it indispensable for maintaining optimal engine performance. Regular maintenance and inspection are essential to ensure the continued effectiveness of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.