This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

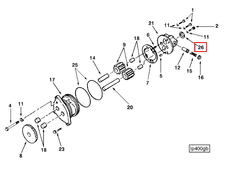

The 207135 Rectangular Ring Seal, manufactured by Cummins, is a specialized component designed for use in commercial truck applications. Cummins, a well-established name in the commercial vehicle industry, produces a range of parts and systems that enhance the performance and reliability of heavy-duty trucks. This Cummins part plays a role in ensuring the efficient operation of truck engines and other systems.

Basic Concepts of Rectangular Ring Seals

Rectangular ring seals are mechanical components used to create a seal between two surfaces. They function by deforming slightly when compressed, filling the gap between the surfaces and preventing the leakage of fluids or gases. These seals are commonly used in various mechanical systems, including engines, hydraulic systems, and pneumatic systems, where maintaining a tight seal is crucial for optimal performance and safety 1.

Purpose of the 207135 Rectangular Ring Seal in Truck Operations

In commercial truck operations, the 207135 Rectangular Ring Seal serves a vital function within the engine and other systems. It is designed to provide a reliable seal in environments where high pressure and temperature fluctuations are common. By ensuring that fluids and gases remain contained within their designated pathways, the seal contributes to the overall efficiency and reliability of the truck’s engine and associated systems 2.

Key Features of the 207135 Rectangular Ring Seal

The 207135 Rectangular Ring Seal is characterized by its specific design and material properties, which enhance its performance and durability. Made from high-quality materials, it is engineered to withstand the demanding conditions found in commercial truck engines. Its rectangular shape allows for a larger sealing surface area compared to traditional O-rings, providing superior sealing capabilities. Additionally, the seal is designed to accommodate slight misalignments between mating surfaces, ensuring a consistent seal even under dynamic conditions 3.

Benefits of Using the 207135 Rectangular Ring Seal

The use of the 207135 Rectangular Ring Seal offers several advantages. Its design allows for improved sealing efficiency, reducing the risk of leaks and enhancing the overall performance of the truck’s engine and systems. The seal’s durability ensures a longer service life, minimizing the need for frequent replacements. Furthermore, its resistance to various operating conditions, including high temperatures and pressures, makes it a reliable choice for commercial truck applications.

Installation Considerations

Proper installation of the 207135 Rectangular Ring Seal is crucial for ensuring optimal performance and longevity. It is important to follow manufacturer guidelines for installation, including the use of the correct tools and techniques to avoid damaging the seal. Ensuring that the mating surfaces are clean and free of debris is also essential for achieving a reliable seal. Additionally, careful attention should be paid to the orientation and positioning of the seal to ensure it functions as intended.

Troubleshooting Common Issues

Common problems associated with rectangular ring seals include leaks, seal extrusion, and premature wear. These issues can often be traced back to improper installation, incorrect sizing, or exposure to incompatible fluids. Troubleshooting steps may include re-evaluating the installation process, checking for proper sizing and fit, and ensuring compatibility with the system’s fluids and operating conditions. In some cases, replacing the seal with a correctly sized and installed one may be necessary to resolve the issue.

Maintenance Tips

Regular maintenance of the 207135 Rectangular Ring Seal can help prolong its service life and maintain its effectiveness. This includes periodic inspections for signs of wear or damage, ensuring that the seal remains properly seated, and checking for any leaks in the system. Additionally, maintaining clean and well-lubricated mating surfaces can contribute to the seal’s performance and longevity. Following the manufacturer’s recommended maintenance schedule and guidelines is key to ensuring the continued reliability of the seal.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial vehicle industry for producing high-quality, reliable components and systems. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ commitment to innovation, quality, and customer satisfaction has made it a trusted name in the industry.

Rectangular Ring Seal (Part 207135) Compatibility with Cummins Engines

The Rectangular Ring Seal, identified by part number 207135, is a critical component in various Cummins engine models. This seal is designed to ensure optimal performance and longevity by preventing leaks and maintaining pressure integrity. Here’s how it fits with the listed engines:

K-Series Engines

- K19

- K38

- K50

The Rectangular Ring Seal is compatible with the K-series engines, including the K19, K38, and K50. These engines are known for their robust design and are often used in heavy-duty applications. The seal ensures that the engine maintains its operational efficiency by preventing unwanted fluid leakage.

KTA19 Series Engines

- KTA19GC

- KTA19GC CM558

For the KTA19GC and KTA19GC CM558 engines, the Rectangular Ring Seal is essential in maintaining the integrity of the engine’s hydraulic and lubrication systems. These engines are typically used in marine and industrial applications, where reliability and performance are paramount.

N-Series Engines

- N14 CELECT

- N14 MECHANICAL

The N14 CELECT and N14 MECHANICAL engines also benefit from the Rectangular Ring Seal. These engines are widely used in various industries, including construction and agriculture, and require a seal that can withstand high pressures and temperatures.

NH/NT Series Engines

- NH/NT 855

The NH/NT 855 engine incorporates the Rectangular Ring Seal to ensure that the engine operates smoothly and efficiently. This engine is known for its versatility and is used in a range of applications, from construction equipment to power generation.

QSK Series Engines

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

The QSK series engines, including the QSK19 CM2350 K105, QSK19 CM2350 K114, QSK19 CM2350 K144G, QSK19 CM500, QSK19 CM850 MCRS, and QSK19G, all utilize the Rectangular Ring Seal. These engines are designed for high-performance applications and require a seal that can handle extreme conditions. The seal ensures that these engines maintain their power output and efficiency, making it a crucial component in their operation.

Role of Part 207135 Rectangular Ring Seal in Engine Systems

The Rectangular Ring Seal, part number 207135, is integral to maintaining the integrity and efficiency of various engine systems. It is specifically designed to ensure proper sealing in applications where rectangular cross-sections are required. Here’s how it integrates with the provided components:

-

Base Parts and Base Parts Less Rgt: The Rectangular Ring Seal is often used in conjunction with base parts to ensure that any fluid or gas passages are sealed effectively. In configurations where the right section is omitted (Base Parts Less Rgt), the seal helps maintain the structural integrity and prevent leaks.

-

Gasket Coupling 2008 Kit and Gasket Coupling 2009 Kit: These kits typically include various gaskets designed to seal different components within the engine. The Rectangular Ring Seal complements these kits by providing additional sealing where standard gaskets may not fit due to the shape of the passage.

-

Gasket Kit: A comprehensive gasket kit will often include a variety of seals to address different sealing requirements. The Rectangular Ring Seal is a specialized component within such kits, used where rectangular seals are necessary.

-

Kit Spares and Overhaul Kit: During an engine overhaul, ensuring all seals are in perfect condition is vital. The Rectangular Ring Seal is a key spare part in these kits, used to replace worn-out seals and maintain the engine’s efficiency.

-

PDC (Power Distribution Center): Though primarily electrical, the PDC may have fluid passages for cooling. The Rectangular Ring Seal ensures these passages are sealed, preventing any coolant leaks that could affect electrical components.

-

Liner Kit: Engine liners require precise sealing to maintain compression and prevent oil leaks. The Rectangular Ring Seal is used in liner kits to ensure that the gaps between the liner and the engine block are effectively sealed.

-

Lower Engine Gasket Kit and Lower Engine Gasket Set: These kits are designed to seal the lower portion of the engine, including the oil pan and crankshaft area. The Rectangular Ring Seal is employed where standard gaskets cannot fit due to the geometry of the engine components.

-

Lubricating Oil Filter, Lubricating Oil Filter Head, Lubricating Oil Mounting Pump, and Lubricating Oil Pump: These components require secure sealing to maintain oil pressure and prevent leaks. The Rectangular Ring Seal is used in the assembly of these parts to ensure that oil passages are sealed correctly.

-

Lubricating Pump Repair Kit: When repairing the lubricating pump, ensuring all seals are intact is essential. The Rectangular Ring Seal is a critical component in this kit, used to replace any worn seals and maintain the pump’s efficiency.

-

Oil Pan: The oil pan must be sealed to the engine block to prevent oil leaks. The Rectangular Ring Seal is used in the gasket set for the oil pan to ensure a tight seal around irregularly shaped passages.

-

Service Coupling 2008 Assembly and Service Coupling 2009 Assembly: These assemblies often require precise sealing to function correctly. The Rectangular Ring Seal is used to ensure that all connections within these assemblies are leak-proof.

-

Short Block Kit: A short block kit includes all the essential components to rebuild the lower part of the engine. The Rectangular Ring Seal is included to ensure that all necessary passages within the engine block are sealed effectively.

Conclusion

In summary, the 207135 Rectangular Ring Seal plays a significant role in ensuring the sealing integrity of various engine components and systems. Its specialized design makes it indispensable in applications where rectangular seals are required. Proper installation, maintenance, and understanding of its compatibility with different Cummins engines are crucial for maximizing its effectiveness and longevity.

References

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.