This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 213045 Orange Ring Seal is a specialized component designed for use in heavy-duty truck applications. This part plays a role in maintaining the integrity of various systems within these vehicles, ensuring efficient operation and longevity. Understanding its purpose and functionality is key to appreciating its importance in the context of heavy-duty truck components.

Basic Concepts of Orange Ring Seals

An Orange Ring Seal is a type of mechanical seal that provides a reliable barrier between different fluids or between a fluid and the environment. It functions by creating a tight seal that prevents leakage, ensuring that systems operate under the correct pressure and conditions. These seals are commonly used in applications where there is a need to contain fluids under pressure, such as in hydraulic systems, fuel systems, and engine compartments 1.

Purpose of the 213045 Orange Ring Seal in Truck Operations

The 213045 Orange Ring Seal serves a vital function in the operation of heavy-duty trucks. It is designed to seal connections within the truck’s systems, preventing fluid leaks that could lead to system failure or inefficiency. By maintaining a secure seal, it ensures that the truck’s systems operate under the correct pressure, contributing to the overall performance and reliability of the vehicle 2.

Key Features of the 213045 Orange Ring Seal

The 213045 Orange Ring Seal is characterized by several design elements that make it suitable for its intended applications. These include its durable construction, which is capable of withstanding high pressures and temperatures, and its precise fit, which ensures a tight seal. Additionally, the seal is made from materials that offer resistance to a wide range of chemicals and operating conditions, enhancing its versatility and reliability 3.

Benefits of Using the 213045 Orange Ring Seal

Utilizing the 213045 Orange Ring Seal offers several advantages. Its design contributes to improved sealing performance, reducing the risk of leaks and system failures. The seal’s durability ensures long-term reliability, even under demanding operating conditions. Furthermore, its resistance to various chemicals and temperatures makes it a versatile choice for a wide range of applications within heavy-duty trucks.

Installation and Maintenance Guidelines

Proper installation and routine maintenance of the 213045 Orange Ring Seal are crucial for ensuring optimal performance and longevity. Installation should be carried out according to manufacturer guidelines, ensuring that the seal is correctly positioned and that all mating surfaces are clean and free from debris. Routine maintenance involves regular inspections for signs of wear or damage, and replacement as necessary to prevent system failures.

Troubleshooting Common Issues

Typical problems that may arise with the 213045 Orange Ring Seal include leaks, which can be caused by improper installation, wear, or damage. Diagnostic steps involve inspecting the seal and its mating surfaces for signs of damage or misalignment. Solutions may include reinstallation, repair, or replacement of the seal, depending on the severity of the issue.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the automotive and heavy-duty truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and global presence make it a trusted partner for businesses and individuals alike.

Cummins Engine Part 213045: Orange Ring Seal

The Cummins part number 213045, an Orange Ring Seal, is a critical component in various Cummins engine models. This seal is essential for maintaining the integrity of the engine’s sealing system, ensuring that there are no leaks and that the engine operates efficiently.

NH/NT 855 Engines

The NH/NT 855 engines are a series of heavy-duty diesel engines produced by Cummins. These engines are known for their durability and reliability, often used in agricultural, construction, and mining applications. The Orange Ring Seal (part 213045) is integral to these engines, providing a tight seal in areas where it is most needed.

Application in NH/NT 855 Engines

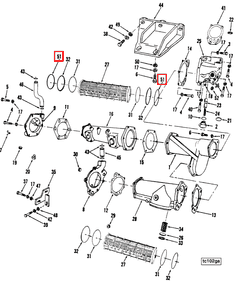

In the NH/NT 855 engines, the Orange Ring Seal is typically used in the following areas:

- Turbocharger Housing: Ensuring that the turbocharger operates efficiently by preventing air leaks.

- Fuel Injection System: Maintaining the integrity of the fuel system by preventing fuel leaks.

- Cooling System: Ensuring that the cooling system operates without leaks, which is crucial for maintaining the engine’s optimal temperature.

Importance of the Seal

The Orange Ring Seal is made from a durable material that can withstand high temperatures and pressures, making it ideal for use in heavy-duty engines like the NH/NT 855. Its primary function is to prevent leaks, which can lead to a loss of performance, increased fuel consumption, and potential engine damage.

Installation and Maintenance

Proper installation of the Orange Ring Seal is crucial to ensure its effectiveness. It should be installed with the correct torque specifications to avoid damage to the seal or the engine components it is sealing. Regular maintenance checks should be performed to ensure the seal remains in good condition and is replaced if any signs of wear or damage are detected.

Compatibility

The Orange Ring Seal (part 213045) is specifically designed for use with Cummins engines, including the NH/NT 855 series. It is important to use genuine Cummins parts to ensure compatibility and maintain the engine’s performance and reliability.

Role of Part 213045 Orange Ring Seal in Engine Systems

The Part 213045 Orange Ring Seal is instrumental in maintaining the integrity and efficiency of various engine systems by ensuring proper sealing in critical junctures.

In the Engine Oil Cooler, the Orange Ring Seal is positioned to prevent oil leaks, thereby maintaining consistent oil pressure and temperature regulation essential for engine longevity.

Within the Lubricating Oil and Turbocharger Cooler system, this seal plays a significant role in preventing oil contamination and ensuring that the lubricating oil remains clean and effective in reducing friction between moving parts.

In the Lubricating Oil and Turbocharger Cooler Assembly, the seal is vital for maintaining the structural integrity of the assembly, preventing any oil leakage that could lead to inefficient cooling and potential engine damage.

For the Lubricating Oil Cooler and its variants, including the Lubricating Oil Cooler and T C Cooler, the Orange Ring Seal ensures that the cooling process is efficient by maintaining a sealed environment, which is essential for optimal engine performance.

In the Oil Cooler and T C Cooler systems, the seal is employed to ensure that the cooling fluids are contained within the system, preventing any loss of coolant that could lead to overheating of engine components.

The Torque Converter Cooler and its associated systems, such as the Torque Converter and Turbocharger Cooler, rely on the Orange Ring Seal to maintain pressure and prevent leaks, ensuring that the torque converter operates within its designed parameters for efficient power transmission.

Overall, the Part 213045 Orange Ring Seal is a fundamental component in these engine systems, contributing to their reliability and efficiency by ensuring that fluids are properly contained and pressures are maintained.

Conclusion

The Cummins 213045 Orange Ring Seal is a critical component in the maintenance and operation of heavy-duty truck engines. Its role in preventing leaks, ensuring system integrity, and contributing to engine efficiency cannot be overstated. Proper installation, maintenance, and the use of genuine Cummins parts are essential for maximizing the performance and longevity of these engines.

-

Robert Bosch GmbH, Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Springer Vieweg, 2007.

↩ -

Michael Hilgers, The Diesel Engine Second Edition, Springer Nature, 2023.

↩ -

Joseph A Bell, Modern Diesel Technology Electricity Electronics, Delmar Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.