This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 217388 Rectangular Ring Seal, manufactured by Cummins, is a critical component in commercial trucks, designed to maintain the integrity of various systems by preventing leaks and ensuring efficient operation. Cummins, a reputable manufacturer in the automotive industry, produces this seal to meet the demanding requirements of heavy-duty applications.

Basic Concepts of Rectangular Ring Seals

A Rectangular Ring Seal is a gasket designed to create a tight seal between two surfaces. It functions by being compressed between the mating surfaces, deforming the seal material to fill any irregularities and create a barrier against fluid or gas leakage. Compared to other seals, such as O-rings or spiral wound gaskets, rectangular ring seals offer specific advantages in applications with high pressure and temperature. They are particularly effective in dynamic sealing applications where there is relative motion between the sealing surfaces 1.

Purpose of the 217388 Rectangular Ring Seal

This Cummins part is employed in commercial trucks to ensure the sealing of various systems, including the fuel system, engine components, and transmission systems. Its role is to maintain system integrity by preventing leaks of fluids such as fuel, oil, or coolant, which are vital for the proper operation of the truck. This seal is applied in environments where it must withstand high pressures and temperatures, as well as dynamic movements.

Key Features

The 217388 Rectangular Ring Seal is characterized by its material composition, typically made from high-performance elastomers or composite materials that offer resistance to a wide range of chemicals and operating conditions. Its design includes a rectangular cross-section that allows for greater surface contact area compared to circular seals, enhancing its sealing capabilities. Additionally, the seal may feature unique characteristics such as anti-extrusion elements or reinforcement materials to improve durability and performance.

Benefits

The use of the 217388 Rectangular Ring Seal provides several benefits, including enhanced sealing efficiency due to its design and material properties. It offers improved durability under high-pressure and high-temperature conditions, ensuring long-term performance. The seal’s ability to accommodate dynamic movements without compromising the seal integrity contributes to its effectiveness in heavy-duty truck applications.

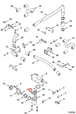

Installation Process

Installing the 217388 Rectangular Ring Seal requires careful attention to ensure its effectiveness. The process involves cleaning the mating surfaces to remove any contaminants that could compromise the seal. The seal should be lubricated with a compatible lubricant to facilitate installation and reduce the risk of damage. It is important to use the correct tools to install the seal without over-compressing it, ensuring that it sits properly within the groove or between the surfaces it is designed to seal. Following manufacturer guidelines for torque specifications and installation procedures is recommended to achieve the best results.

Common Issues and Troubleshooting

Common issues with the 217388 Rectangular Ring Seal may include leaks due to improper installation, wear from dynamic movements, or degradation from exposure to harsh chemicals or operating conditions. Troubleshooting these issues involves inspecting the seal for signs of damage or wear, ensuring that it is correctly installed, and verifying that the mating surfaces are clean and free from imperfections. In cases where the seal is worn or damaged, replacement with a new seal is necessary to restore system integrity.

Maintenance Tips

To ensure the longevity and optimal performance of the 217388 Rectangular Ring Seal, regular maintenance is recommended. This includes periodic inspection of the seal for signs of wear or damage, cleaning the mating surfaces to prevent contamination, and replacing the seal according to the manufacturer’s recommendations or when signs of degradation are observed. Adhering to these maintenance practices helps to maintain the seal’s effectiveness and contribute to the overall reliability of the truck’s systems.

Cummins Overview

Cummins is a manufacturer with a long-standing reputation in the automotive and heavy-duty truck industries. Known for its commitment to quality and innovation, Cummins produces a wide range of components designed to meet the rigorous demands of commercial vehicles. The company’s history of excellence and dedication to advancing automotive technology underscores its position as a trusted provider of high-performance parts, including the 217388 Rectangular Ring Seal 2.

Role of Part 217388 Rectangular Ring Seal in Engine Systems

The 217388 Rectangular Ring Seal is instrumental in ensuring the integrity and efficiency of various engine systems. Its application is particularly significant in the following components:

Fuel Control Module

In the Fuel Control Module, the Rectangular Ring Seal is used to maintain a secure seal between the module and its housing. This ensures that fuel delivery is precise and uncontaminated, which is essential for optimal engine performance and fuel efficiency.

Heat Exchanger and Heat Exchanger Systems

Within Heat Exchanger systems, the seal plays a key role in preventing leaks between the coolant and the engine oil. This separation is vital for maintaining the correct temperature gradients necessary for efficient heat transfer and engine cooling.

Keel Cooling System

In the Keel Cooling System, the Rectangular Ring Seal is employed to ensure a tight seal around the cooling passages. This helps in maintaining the structural integrity of the keel and preventing any coolant loss, which is essential for consistent cooling performance.

Engine Control Module

The Engine Control Module relies on the Rectangular Ring Seal to ensure that electrical connections remain secure and free from moisture or contaminants. This is important for the reliable operation of the engine’s electronic systems.

Oil Pan

In the Oil Pan, the seal is used to create a robust barrier that prevents oil leaks. This is essential for maintaining proper lubrication levels and protecting the engine from damage due to oil starvation.

Water Transfer Connection

Finally, in the Water Transfer Connection, the Rectangular Ring Seal ensures that the transfer of coolant between different parts of the engine system is efficient and leak-free. This is important for consistent engine temperature management and overall system reliability.

Conclusion

The 217388 Rectangular Ring Seal plays a vital role in the maintenance and efficiency of commercial truck systems. Its design and material properties make it well-suited for high-pressure and high-temperature applications, ensuring long-term performance and reliability. Proper installation, regular maintenance, and understanding its role in various engine systems are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.