This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2870453 O-Ring Seal is a component designed to ensure the integrity of fluid systems within commercial trucks. Its role is to prevent leaks and maintain system efficiency, contributing to the overall performance and reliability of the vehicle 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, used to create a seal between two or more parts. It operates by being compressed within a groove, forming a barrier that prevents the passage of fluids or gases. O-Ring Seals are widely utilized in mechanical systems for their simplicity and effectiveness in sealing applications 2.

Purpose of the 2870453 O-Ring Seal in Truck Operation

This Cummins part is specifically designed to function within the fluid systems of commercial trucks. It is associated with components such as fuel injectors, where it plays a role in maintaining the seal around moving parts, ensuring that fuel is delivered efficiently without leakage. This seal is integral to the operation of the fuel system, contributing to the engine’s performance and the truck’s overall efficiency 3.

Key Features of the 2870453 O-Ring Seal

The 2870453 O-Ring Seal is characterized by its material composition, typically made from nitrile rubber, which offers resistance to a variety of chemicals and temperatures encountered in truck applications. Its design specifications include precise dimensions to ensure a proper fit within the designated grooves, enhancing its durability and effectiveness in sealing applications 4.

Benefits of Using the 2870453 O-Ring Seal

Utilizing this part provides several advantages, including improved system performance through effective sealing, enhanced longevity due to its durable material composition, and increased reliability in demanding truck applications. These benefits contribute to the overall efficiency and maintenance of the vehicle 5.

Installation Considerations

For optimal performance and longevity, this Cummins part should be installed according to manufacturer guidelines. This includes ensuring the groove is clean and free of debris before installation, using the appropriate lubrication to facilitate seating, and avoiding over-tightening which could damage the seal 6.

Common Issues and Troubleshooting

Typical problems associated with O-Ring Seals include leaks due to wear, improper installation, or exposure to incompatible fluids. Diagnosing these issues involves inspecting the seal for signs of damage or deformation and ensuring it is correctly seated within the groove. Recommended troubleshooting steps may include replacing the seal if damage is detected or re-evaluating the installation process 7.

Maintenance Tips

To prolong the life of the 2870453 O-Ring Seal, routine maintenance practices should be observed. This includes regular inspections for signs of wear or damage, adhering to recommended replacement schedules, and ensuring that the seal is compatible with the fluids and operating conditions of the truck’s system 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a comprehensive product range, Cummins has established a reputation for quality and reliability in the commercial truck industry, providing solutions that enhance the performance and efficiency of vehicles worldwide 9.

Application in Cummins Engines

QSK60 G and CM2358 K110 Engines

The O-Ring Seal part 2870453 is integral to the operation of the QSK60 G and CM2358 K110 engines. These engines, known for their robust performance and reliability, benefit from the seal’s ability to maintain system integrity under high-pressure conditions. The seal’s placement in these engines is crucial for ensuring that the engine operates smoothly and efficiently, minimizing the risk of leaks that could lead to performance degradation or damage 10.

QSK60G Engine

Similarly, the QSK60G engine also utilizes the O-Ring Seal part 2870453. This seal plays a vital role in the engine’s hydraulic and lubrication systems, where it helps to maintain the necessary pressure and prevent fluid loss. Its application in the QSK60G engine underscores its importance in maintaining the engine’s operational efficiency and longevity 11.

Role of Part 2870453 O-Ring Seal in Engine Systems

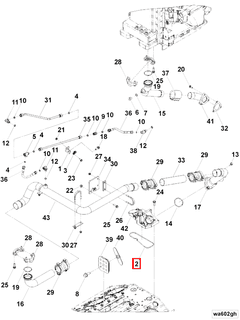

Cooling System Gasket Kit

In the cooling system gasket kit, the O-Ring Seal plays a significant role in maintaining the integrity of the cooling system. It ensures that coolant flows smoothly without leaks, which is essential for regulating engine temperature and preventing overheating. The seal is positioned at critical junctions where coolant passages meet, providing a tight seal that withstands the pressure and temperature variations within the cooling system 12.

Plumbing

When it comes to the plumbing of engine systems, the O-Ring Seal is used to create secure connections between various pipes and fittings. This is particularly important in fuel lines, oil passages, and hydraulic systems where any leakage can lead to system failure or contamination. The seal’s elasticity allows it to conform to the surfaces it contacts, ensuring a leak-proof connection that can endure vibrations and movement typical in engine operations 13.

Aftercooler Water System

In the aftercooler water system, the O-Ring Seal is employed to seal connections in the water passages that cool the compressed air from the turbocharger. This system relies on the seal to maintain pressure and prevent water leaks, which ensures efficient cooling and optimal performance of the aftercooler. The seal’s resistance to water and various coolants makes it suitable for this application 14.

Auxiliary Cooling

For auxiliary cooling systems, which may include oil coolers or transmission coolers, the O-Ring Seal is used to seal the connections in the cooling lines. This ensures that the cooling fluid circulates effectively without any loss, maintaining the temperature of critical components such as engine oil or transmission fluid. The seal’s durability under varying temperatures and pressures is vital for the longevity and efficiency of the auxiliary cooling system 15.

Conclusion

The Cummins 2870453 O-Ring Seal is a vital component in the maintenance and operation of commercial truck engines. Its role in preventing leaks, ensuring system efficiency, and contributing to the overall performance and reliability of the vehicle cannot be overstated. Proper installation, maintenance, and understanding of its application across various engine systems are key to maximizing the benefits of this part.

-

Quansheng Zhan, Shengbo Eben, Li Kun Deng, Automotive Heating Ventilation and Air Conditioning, Jones Bartlett Learning, 2018.

↩ -

MJ Nunney, Light and Heavy Vehicle Technology, Fourth Edition, Butterworth-Heinemann, 2007.

↩ -

Paul Dempsey, Troubleshooting and Repairing Diesel Engines, 5th Edition, McGraw-Hill, 2018.

↩ -

John Kasab and Andrea Strzelec, Automotive Emissions Regulations and Exhaust Aftertreatment Systems, SAE International, 2020.

↩ -

Quansheng Zhan, Shengbo Eben, Li Kun Deng, Automotive Heating Ventilation and Air Conditioning, Jones Bartlett Learning, 2018.

↩ -

MJ Nunney, Light and Heavy Vehicle Technology, Fourth Edition, Butterworth-Heinemann, 2007.

↩ -

Paul Dempsey, Troubleshooting and Repairing Diesel Engines, 5th Edition, McGraw-Hill, 2018.

↩ -

John Kasab and Andrea Strzelec, Automotive Emissions Regulations and Exhaust Aftertreatment Systems, SAE International, 2020.

↩ -

Quansheng Zhan, Shengbo Eben, Li Kun Deng, Automotive Heating Ventilation and Air Conditioning, Jones Bartlett Learning, 2018.

↩ -

MJ Nunney, Light and Heavy Vehicle Technology, Fourth Edition, Butterworth-Heinemann, 2007.

↩ -

Paul Dempsey, Troubleshooting and Repairing Diesel Engines, 5th Edition, McGraw-Hill, 2018.

↩ -

John Kasab and Andrea Strzelec, Automotive Emissions Regulations and Exhaust Aftertreatment Systems, SAE International, 2020.

↩ -

Quansheng Zhan, Shengbo Eben, Li Kun Deng, Automotive Heating Ventilation and Air Conditioning, Jones Bartlett Learning, 2018.

↩ -

MJ Nunney, Light and Heavy Vehicle Technology, Fourth Edition, Butterworth-Heinemann, 2007.

↩ -

Paul Dempsey, Troubleshooting and Repairing Diesel Engines, 5th Edition, McGraw-Hill, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.